CFBC, preferred Technology for lignite fuel - Experiences - Infraline

CFBC, preferred Technology for lignite fuel - Experiences - Infraline

CFBC, preferred Technology for lignite fuel - Experiences - Infraline

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

separate norms in respect of Auxiliary Power Consumption, reimbursement of complete<br />

<strong>fuel</strong> additive charges, if necessary.<br />

Introduction<br />

India has total estimated usable <strong>lignite</strong> reserves of 97,000 MMT , concentrated in the<br />

states of Tamilnadu, Gujarat and Rajasthan. Tamilnadu has 70,000 million Tones,<br />

Rajasthan has15,000 million Tones, Gujarat has 12,000 million Tones. All these states<br />

are far away from coal reserves located in India. It is economical to use <strong>lignite</strong> <strong>for</strong> power<br />

generation in these areas. These are more than 30% of coal reserves available in India.<br />

Estimated power generation capacity addition with this <strong>lignite</strong> reserves is around<br />

3,00,000 MW <strong>for</strong> 50 years. India has not exploited <strong>lignite</strong> reserves available <strong>for</strong> power<br />

generation as it has to be considering the available resources. Per<strong>for</strong>mance of units with<br />

PF technology using <strong>lignite</strong> has been low. Per<strong>for</strong>mance of Units with <strong>CFBC</strong><br />

technology using <strong>lignite</strong> is encouraging.<br />

<strong>CFBC</strong> operates with combustor temperatures in the region of 850 – 900 deg C. These<br />

combustor temperatures are much lower than ash fusion temperature. So, in <strong>CFBC</strong><br />

boilers problem of any clinker <strong>for</strong>mation is not encountered with <strong>lignite</strong> as primary <strong>fuel</strong>.<br />

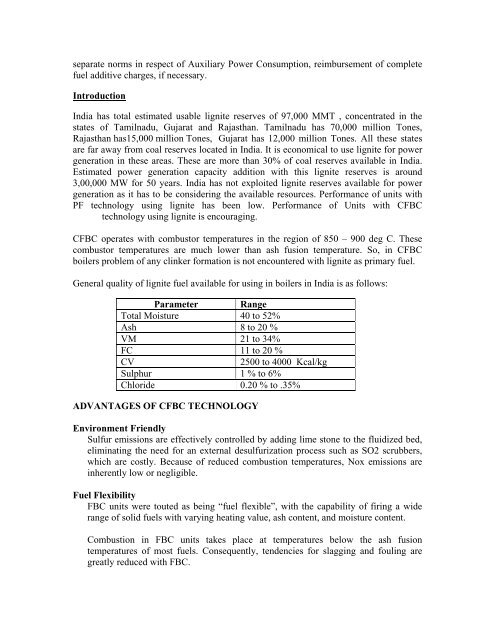

General quality of <strong>lignite</strong> <strong>fuel</strong> available <strong>for</strong> using in boilers in India is as follows:<br />

Parameter Range<br />

Total Moisture 40 to 52%<br />

Ash 8 to 20 %<br />

VM 21 to 34%<br />

FC 11 to 20 %<br />

CV<br />

2500 to 4000 Kcal/kg<br />

Sulphur 1 % to 6%<br />

Chloride 0.20 % to .35%<br />

ADVANTAGES OF <strong>CFBC</strong> TECHNOLOGY<br />

Environment Friendly<br />

Sulfur emissions are effectively controlled by adding lime stone to the fluidized bed,<br />

eliminating the need <strong>for</strong> an external desulfurization process such as SO2 scrubbers,<br />

which are costly. Because of reduced combustion temperatures, Nox emissions are<br />

inherently low or negligible.<br />

Fuel Flexibility<br />

FBC units were touted as being “<strong>fuel</strong> flexible”, with the capability of firing a wide<br />

range of solid <strong>fuel</strong>s with varying heating value, ash content, and moisture content.<br />

Combustion in FBC units takes place at temperatures below the ash fusion<br />

temperatures of most <strong>fuel</strong>s. Consequently, tendencies <strong>for</strong> slagging and fouling are<br />

greatly reduced with FBC.