CFBC, preferred Technology for lignite fuel - Experiences - Infraline

CFBC, preferred Technology for lignite fuel - Experiences - Infraline

CFBC, preferred Technology for lignite fuel - Experiences - Infraline

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>CFBC</strong> boiler is operational friendly. This boiler is called dark boiler because of<br />

absence of any flame in the combustor. Hence, there is no boiler tripping due to flame<br />

failure/ furnace disturbance. As this boiler has huge refractory and very large amount<br />

of bed ash in circulation, there is no need to trip the turbine in case of all <strong>fuel</strong> cut off<br />

to boiler <strong>for</strong> about 20 minutes. Boiler continues generating steam within specified<br />

parameters <strong>for</strong> sustaining turbine at reduced loads. <strong>CFBC</strong> combustor is a reservoir of<br />

heat energy. This energy is used in case of all <strong>fuel</strong> failure <strong>for</strong> short duration be<strong>for</strong>e<br />

restoration of one of the <strong>fuel</strong> available (<strong>lignite</strong> or oil). <strong>CFBC</strong> boilers do not<br />

experience large sharp fluctuations in boiler pressure due to very stable firing system.<br />

Oil support is not required even at part loads of about 25 % and combustor<br />

temperatures, steam parameters are maintained. <strong>CFBC</strong> boilers have almost zero<br />

combustibles in bottom ash with share of bottom ash of about 30-40%. The intense<br />

heat storage capacity of this boiler makes it useful <strong>for</strong> quick hot re-starts.<br />

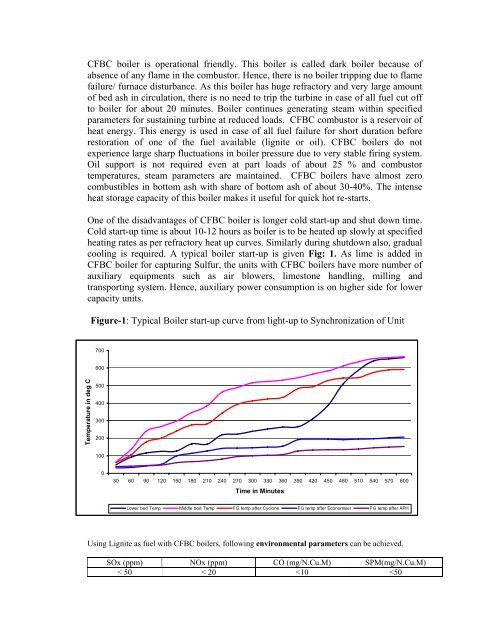

One of the disadvantages of <strong>CFBC</strong> boiler is longer cold start-up and shut down time.<br />

Cold start-up time is about 10-12 hours as boiler is to be heated up slowly at specified<br />

heating rates as per refractory heat up curves. Similarly during shutdown also, gradual<br />

cooling is required. A typical boiler start-up is given Fig: 1. As lime is added in<br />

<strong>CFBC</strong> boiler <strong>for</strong> capturing Sulfur, the units with <strong>CFBC</strong> boilers have more number of<br />

auxiliary equipments such as air blowers, limestone handling, milling and<br />

transporting system. Hence, auxiliary power consumption is on higher side <strong>for</strong> lower<br />

capacity units.<br />

Figure-1: Typical Boiler start-up curve from light-up to Synchronization of Unit<br />

700<br />

600<br />

Temperature in deg C<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

30 60 90 120 150 180 210 240 270 300 330 360 390 420 450 480 510 540 570 600<br />

Time in Minutes<br />

Lower bed Temp Middle bed Temp FG temp after Cyclone FG temp after Economiser FG temp after APH<br />

Using Lignite as <strong>fuel</strong> with <strong>CFBC</strong> boilers, following environmental parameters can be achieved.<br />

SOx (ppm) NOx (ppm) CO (mg/N.Cu.M) SPM(mg/N.Cu.M)<br />

< 50 < 20