CFBC, preferred Technology for lignite fuel - Experiences - Infraline

CFBC, preferred Technology for lignite fuel - Experiences - Infraline

CFBC, preferred Technology for lignite fuel - Experiences - Infraline

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Simplified Fuel Preparation And Feeding<br />

Normally crushers are sufficient <strong>for</strong> <strong>fuel</strong> preparation. A top size, in the range of 5 –<br />

12 mm is required <strong>for</strong> sub-bituminous coals. Pulverizes and associated maintenance<br />

are eliminated.<br />

Compact Plant Design<br />

<strong>CFBC</strong> boilers require less floor space than conventional steam generators with down<br />

stream flue gas cleaning equipment.<br />

Sustainability Under Cyclic Loading<br />

Minimizes stress on boiler tube material with low variation of combustor<br />

temperatures under cyclic loading of boiler particularly under varying grid<br />

frequencies.<br />

High Reliability<br />

Low flue gas velocities in combustor minimizes erosion and hence the boiler tube<br />

failures leading to very high reliability of the boiler.<br />

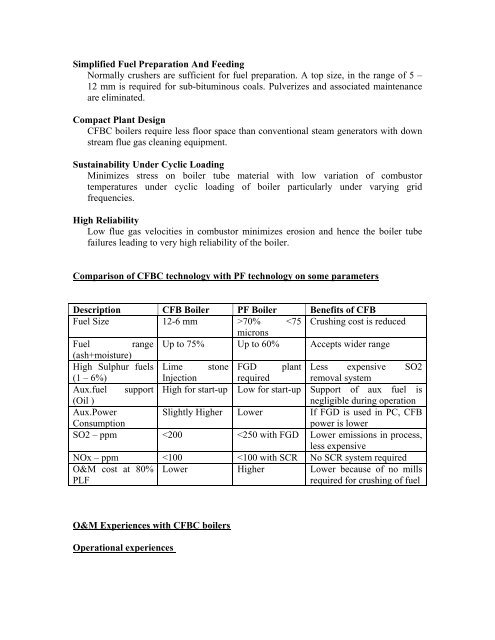

Comparison of <strong>CFBC</strong> technology with PF technology on some parameters<br />

Description CFB Boiler PF Boiler Benefits of CFB<br />

Fuel Size 12-6 mm >70%