Untitled

Untitled

Untitled

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Discharge Bypass Valves<br />

As the suction pressure (P1) falls below the pilot valve’s setting, the<br />

pilot port modulates open. This bleeds refrigerant from the chamber<br />

above the piston through the pilot valve at a faster rate than it is entering,<br />

so the pressure decreases. As this pressure (P3) plus the pressure<br />

from the spring (Ps) falls below the inlet pressure (P2), the inlet<br />

pressure pushes the piston up, modulating the valve open. As the suction<br />

pressure rises above the setting of the pilot valve, the pilot port<br />

modulates closed. This allows pressure to build on top of the main<br />

piston. As this pressure (P3) approaches the inlet pressure (P2), the<br />

force combined with the force from the spring (Ps) pushes the piston<br />

down, modulating the valve closed.<br />

Adjustment Ranges Pressure Setting<br />

Adjustable Spring Heads on Direct Acting Valves<br />

The adjustable type utilizes a spring assembly which can be fixed at<br />

the desired pressure setting (opening pressure). This setting will not<br />

be affected by other factors such as ambient or hot gas temperatures.<br />

The HGBE-5 is available with an adjustment range of 95/115 psig<br />

CATALOG 410A — Page 37<br />

410A<br />

(6.6/7.93 bar). The standard factory setting for this valve is 105 psig<br />

(7.24 bar).<br />

Pilot Operated Valves<br />

The HGBE-8 is adjustable from 75 to 150 psi (5.2 to 10.3 bar). The<br />

standard factory setting is 110 psig (7.58 bar). Adjustment is made by<br />

turning the adjustment screw on the pilot valve. Turning this screw<br />

clockwise will increase the valve’s setting and a counterclockwise<br />

rotation will decrease the valve’s setting.<br />

Adjusting these valves can be complicated because the load must be<br />

varied during the setting procedure. The load on the system must be<br />

decreased to lower the suction pressure so that the valve can control.<br />

The valve should then be adjusted to maintain the desired pressure.<br />

The load on the system should then be increased to raise the suction<br />

pressure above the valve setting to close the valve. Once this is<br />

accomplished, the valve setting can be checked by slowly decreasing<br />

the load until the discharge bypass valve begins to open (a hissing<br />

sound and/or an accompanying pressure rise at the outlet connection<br />

will indicate that the bypass valve has opened).<br />

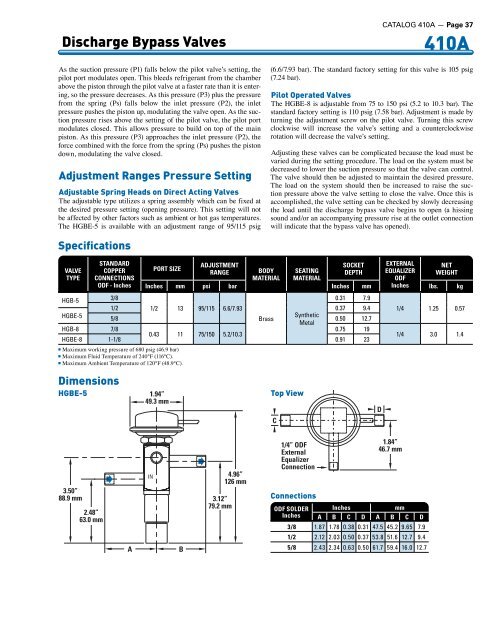

Specifications<br />

VALVE<br />

TYPE<br />

STANDARD<br />

COPPER<br />

CONNECTIONS<br />

ODF - Inches<br />

ADJUSTMENT<br />

SOCKET EXTERNAL NET<br />

PORT SIZE<br />

RANGE<br />

BODY SEATING DEPTH EQUALIZER WEIGHT<br />

MATERIAL MATERIAL<br />

ODF<br />

Inches mm psi bar Inches mm Inches lbs. kg<br />

HGB-5<br />

3/8<br />

0.31 7.9<br />

1/2 1/2 13 95/115 6.6/7.93<br />

0.37 9.4<br />

HGBE-5<br />

Synthetic<br />

5/8 Brass<br />

0.50 12.7<br />

Metal<br />

HGB-8 7/8<br />

0.75 19<br />

0.43 11 75/150 5.2/10.3<br />

HGBE-8 1-1/8 0.91 23<br />

n Maximum working pressure of 680 psig (46.9 bar)<br />

n Maximum Fluid Temperature of 240°F (116°C).<br />

n Maximum Ambient Temperature of 120°F (48.9°C).<br />

1/4 1.25 0.57<br />

1/4 3.0 1.4<br />

Dimensions<br />

HGBE-5<br />

1.94”<br />

49.3 mm<br />

Top View<br />

C<br />

D<br />

3.50”<br />

88.9 mm<br />

2.48”<br />

63.0 mm<br />

A<br />

IN<br />

B<br />

3.12”<br />

79.2 mm<br />

4.96”<br />

126 mm<br />

1/4” ODF<br />

External<br />

Equalizer<br />

Connection<br />

Connections<br />

ODF SOLDER<br />

Inches<br />

1.84”<br />

46.7 mm<br />

Inches<br />

mm<br />

A B C D A B C D<br />

3/8 1.87 1.78 0.38 0.31 47.5 45.2 9.65 7.9<br />

1/2 2.12 2.03 0.50 0.37 53.8 51.6 12.7 9.4<br />

5/8 2.43 2.34 0.63 0.50 61.7 59.4 16.0 12.7