Salt Disposal of Heat-Generating Nuclear Waste

Salt Disposal of Heat-Generating Nuclear Waste

Salt Disposal of Heat-Generating Nuclear Waste

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

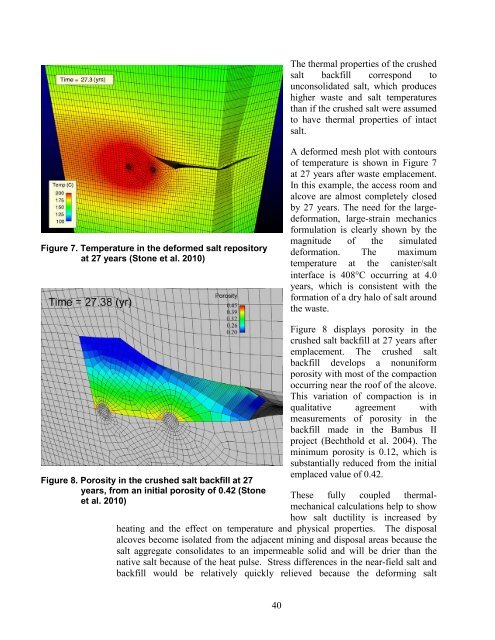

The thermal properties <strong>of</strong> the crushed<br />

salt backfill correspond to<br />

unconsolidated salt, which produces<br />

higher waste and salt temperatures<br />

than if the crushed salt were assumed<br />

to have thermal properties <strong>of</strong> intact<br />

salt.<br />

Figure 7. Temperature in the deformed salt repository<br />

at 27 years (Stone et al. 2010)<br />

A deformed mesh plot with contours<br />

<strong>of</strong> temperature is shown in Figure 7<br />

at 27 years after waste emplacement.<br />

In this example, the access room and<br />

alcove are almost completely closed<br />

by 27 years. The need for the largedeformation,<br />

large-strain mechanics<br />

formulation is clearly shown by the<br />

magnitude <strong>of</strong> the simulated<br />

deformation. The maximum<br />

temperature at the canister/salt<br />

interface is 408°C occurring at 4.0<br />

years, which is consistent with the<br />

formation <strong>of</strong> a dry halo <strong>of</strong> salt around<br />

the waste.<br />

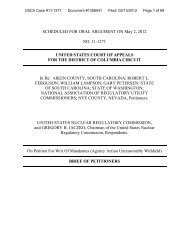

Figure 8. Porosity in the crushed salt backfill at 27<br />

years, from an initial porosity <strong>of</strong> 0.42 (Stone<br />

et al. 2010)<br />

Figure 8 displays porosity in the<br />

crushed salt backfill at 27 years after<br />

emplacement. The crushed salt<br />

backfill develops a nonuniform<br />

porosity with most <strong>of</strong> the compaction<br />

occurring near the ro<strong>of</strong> <strong>of</strong> the alcove.<br />

This variation <strong>of</strong> compaction is in<br />

qualitative agreement with<br />

measurements <strong>of</strong> porosity in the<br />

backfill made in the Bambus II<br />

project (Bechthold et al. 2004). The<br />

minimum porosity is 0.12, which is<br />

substantially reduced from the initial<br />

emplaced value <strong>of</strong> 0.42.<br />

These fully coupled thermalmechanical<br />

calculations help to show<br />

how salt ductility is increased by<br />

heating and the effect on temperature and physical properties. The disposal<br />

alcoves become isolated from the adjacent mining and disposal areas because the<br />

salt aggregate consolidates to an impermeable solid and will be drier than the<br />

native salt because <strong>of</strong> the heat pulse. Stress differences in the near-field salt and<br />

backfill would be relatively quickly relieved because the deforming salt<br />

40