You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A measured step forward<br />

Product range<br />

Dosing<br />

Conveying<br />

Control<br />

Liquids<br />

Gases<br />

Systems

Lutz-Jesco<br />

The right decision for innovation and progress<br />

Water – the fount of life,<br />

a valuable resource, and yet it is taken for granted<br />

to turn on the tap and the clear, fresh and pure<br />

water bubbles out. But the consumption rises<br />

continuously in industry as well as in private<br />

households. Therefore application-oriented water<br />

treatment becomes more and more important. The<br />

innovative system solutions by Lutz-Jesco make<br />

an important contribution to the provision and<br />

treatment of potable, pool and industrial water.<br />

Through intense research and development new<br />

standards are set.<br />

2

Lutz-Jesco Service<br />

At hand world-wide<br />

Argentina<br />

Armenia<br />

Australia<br />

Austria<br />

Bahrain<br />

Bangladesh<br />

Belgium<br />

Bolivia<br />

Bosnia - Herzegovina<br />

Botswana<br />

Brazil<br />

Bulgaria<br />

Canada<br />

Chile<br />

China<br />

Colombia<br />

Cyprus<br />

Czech Republic<br />

Egypt<br />

Estonia<br />

Finland<br />

France<br />

Greece<br />

Jordan<br />

Hong Kong<br />

Hungary<br />

Iceland<br />

India<br />

Indonesia<br />

Iran<br />

Ireland<br />

Israel<br />

Italy<br />

Kenya<br />

Korea<br />

Kosovo<br />

Kuwait<br />

Latvia<br />

Lebanon<br />

Macedonia<br />

Malaysia<br />

Mexico<br />

Morocco<br />

Namibia<br />

Netherlands<br />

New Zealand<br />

Nigeria<br />

Norway<br />

Pakistan<br />

Peru<br />

Philippines<br />

Poland<br />

Portugal<br />

Qatar<br />

South Africa<br />

Romania<br />

Russia<br />

Saudi Arabia<br />

Serbia and Montenegro<br />

Singapore<br />

Slovakia<br />

Slovenia<br />

Spain<br />

Sri Lanka<br />

Swaziland<br />

Sweden<br />

Switzerland<br />

Syria<br />

Taiwan<br />

Thailand<br />

Tunesia<br />

Turkey<br />

UK<br />

Ukraine<br />

Uruguay<br />

USA<br />

Uzbekistan<br />

Venezuela<br />

Vietnam<br />

Zambia<br />

Zimbabwe<br />

For Lutz-Jesco service means:<br />

Be available, wherever you need us.<br />

Therefore Lutz-Jesco is represented<br />

by partners worldwide.<br />

Inspected and certified<br />

3

And what can we do for you?<br />

Drop by drop or with maximum flow, at tropical<br />

temperatures and even this possibly in a really<br />

“caustic“ environment: The demands on dosing<br />

pumps being as variable as the application as the<br />

possibilities and tasks themselves, Lutz-Jesco offers<br />

individual solutions for each field of application. The<br />

extensive product program ranges from the lowcost<br />

precisely operating solenoid-driven dosing<br />

pump to the “heavy-duty“ motor-driven<br />

diaphragm dosing pump, and last but not least,<br />

to the piston dosing pump for high pressures up<br />

to 200 bar. All of them dosing liquids of differing<br />

viscosities, mostly chemically aggressive and toxic,<br />

sometimes even abrasive or effervescent.<br />

4

Lutz-Jesco dosing pumps<br />

A comprehensive range<br />

5

MAGDOS LT<br />

Economical and precise<br />

A measured step forward<br />

The new MAGDOS LT stands for maximum efficiency at a reasonable price<br />

Here is what you can count on in future:<br />

The new solenoid-driven diaphragm dosing<br />

pumps MAGDOS LT work economically, reliably<br />

and flexibly – at ambient temperatures of up to 45 °C.<br />

A brand new microprocessor-controlled electronic<br />

unit guarantees optimum energy consumption and<br />

flexible pressure adjustment. Double-ball valves<br />

ensure highest accuracy even at smallest flow<br />

rates. MAGDOS LT pumps are fitted with a powerful<br />

stroke solenoid, the flow rate per stroke can be<br />

adjusted without steps. MAGDOS LT pumps have<br />

a distinct design and are absolutely easy to maintain.<br />

A good return on your investment.<br />

The pump suited to its task<br />

MAGDOS LT solenoid-driven dosing pumps are especially suitable for water<br />

treatment and the process industry. The hermetically sealed pumps can be<br />

used universally due to the reliable PVC material and a PTFE diaphragm.<br />

Changing requirements is not a challenge, the new MAGDOS LT pumps allow<br />

an adjusting ratio of 1 : 20, thus enabling you to carry out your process<br />

corrections with a turn of the wrist.<br />

In short<br />

• Capacity range 0.2 to 17 l/h, at up to 16 bar<br />

• Suitable for toxic and aggressive media<br />

• Usable at ambient temperatures of up to 45 °C<br />

• Adjusting ratio 1 : 20<br />

• Internal operation and control by pulses<br />

• Double-ball valves for highest accuracy<br />

• Intelligent control<br />

• Convenient single-button operation<br />

MAGDOS LT<br />

6

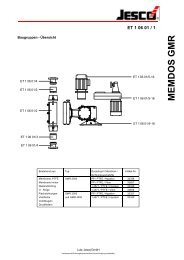

MEMDOS DX<br />

Strong and durable<br />

Always the right choice<br />

The MEMDOS DX motor driven diaphragm<br />

dosing pump does not only stand out for its<br />

performance but also for its reliability, versatility<br />

and user-friendliness: The control is easy to<br />

understand and to operate. MEMDOS DX diaphragm<br />

dosing pumps are totally leakage-free and thus<br />

also suitable for toxic and aggressive media. On<br />

request, the MEMDOS DX pumps can also be<br />

supplied with a double-diaphragm system. Then<br />

uncontrolled leakage of media is avoided even if<br />

the dosing diaphragm wears out.<br />

A really “clean“ solution for numerous applications: MEMDOS DX<br />

Riding on the crest of the waves<br />

Wherever high flow rates in controlled processes are required e.g. in<br />

sewage treatment plants. The MEMDOS DX can be counted on. Thanks<br />

to the sturdy tappet drive with manual or automatic capacity adjustment,<br />

acids, lyes, precipitating agents and flocculents are dosed reliably and<br />

precisely.<br />

MEMDOS DX<br />

In short<br />

Motor driven diaphragm pumps general<br />

• Capacity range 4 to 380 l/h, at up to 10 bar<br />

• Viscosities up to 3,000 mPa*s<br />

• PTFE diaphragm<br />

• Tappet drive<br />

• Manual and automatic capacity adjustment<br />

• Wide range of materials<br />

• Double-diaphragm system on request<br />

7

FEDOS DX<br />

Flexible and heavy-duty<br />

Precision at high pressure<br />

Conditioning for steam generators: no problem with the FEDOS DX<br />

The “intelligent“ FEDOS DX piston dosing pump<br />

operates against up to 100 bar at a capacity range<br />

of 0.1 to 30 l/h – and still meters precisely to the<br />

milliliter. How does this work? It’s quite simple: The<br />

flow rate changes proportionally to the stroke<br />

length and is reproducible even for smallest<br />

capacities.<br />

No extras<br />

FEDOS DX pumps are integrated directly into the process. The control processes<br />

the controller signal without any additional frequency converters. The “intelligence”<br />

of the dosing pump pays off. The control is easy to understand and clear.<br />

In short<br />

piston pumps in general<br />

• Capacity range 0.1 to 4,200 l/h, at up to 200 bar<br />

• Tappet drive with easy-to-operate capacity adjustment<br />

• Reliable and proven hydraulical part<br />

• KARDOS with linear amplitude adjustment<br />

• Ceramic and stainless steel piston<br />

• Flushing ring as standard equipment<br />

• Also suitable for frequency converter operation<br />

• Intelligence due to different operating modes<br />

• Easy and intuitive to operate<br />

FEDOS DX<br />

8

Accessories<br />

A pattern of success<br />

Everything fits<br />

Even the best dosing pump can still be improved<br />

– namely by the right technical periphery, which,<br />

in fact, is the reason for the particularly extensive<br />

accessories program of Lutz-Jesco. It converts<br />

your dosing pump into an efficient dosing system.<br />

Should you have any additional requests: We always<br />

find a solution.<br />

Thought out to the last detail: the accessories program of Lutz-Jesco<br />

In short<br />

Valve assembly<br />

• Available in all standard materials<br />

• Perfectly user-friendly<br />

• Increases the dosing accuracy<br />

• Simplifies the handling<br />

• Improves the working reliability<br />

• For an optimum automation level<br />

Inline pulsation dampener<br />

9

Chlorination<br />

Everything perfectly put in order<br />

Simple, safe, reliable<br />

Chlorine and chlorine coumpounds have been used<br />

successfully in water treatment for many decades.<br />

Lutz-Jesco offers you an extensive range of wellestablished<br />

equipment as well as of state-of-theart<br />

chlorination systems for dosing chlorine gas and<br />

chlorine compounds. Chlorinator, analyzing and<br />

warning devices match perfectly. All Lutz-Jesco<br />

chlorination units meet the safety requirements<br />

according to German standard DIN 19606 by vacuum<br />

technology, mostly full vacuum starting at the chlorine<br />

tank.<br />

Ready in parallel<br />

Full vacuum in battery operation<br />

Compact full vacuum chlorinator C 2212<br />

Small and compact<br />

For single-cylinder installations or installations with a pressure manifold.<br />

The full vacuum chlorinator C 2212 is the compact, functional answer. With<br />

residual pressure protection. With adjusting valve, flow meter, pressure<br />

gauge and integrated safety valve. Operational range up to 4 kg Cl 2 /h.<br />

The full vacuum chlorinator C 2211 allows simultaneous<br />

emptying of cylinder batteries. The vacuum<br />

regulator is fitted with a special adjusting facility. A<br />

flow limiter prevents the cylinder from icing.<br />

Operational range up to 10 kg Cl 2 /h (without<br />

flow limiter). Residual pressure preservation for the<br />

pressure gas tank, the pressure gauge as standard<br />

equipment and the diaphragm pressure regulator<br />

provide additional protection.<br />

In short<br />

• Economic, functional design<br />

• Meet DIN 19606/19643<br />

• Pressure gauge at inlet valve<br />

• Residual pressure preservation for<br />

protection against humidity<br />

Full vacuum chlorinator C 2211<br />

Full vacuum chlorinator C 2212<br />

10

Chlorination<br />

Everything perfectly put in order<br />

Sturdy and precise<br />

The C 7700 is the final control element in<br />

automatically operated chlorination installations<br />

working according to the vacuum method. Its reliability<br />

and linear characteristic curves leave a clear<br />

impression. The valve is suitable for proportional<br />

dosing as well as for automatic control systems.<br />

Control range from 0 - 80 g Cl2/h to 0 - 200 kg<br />

Cl 2 /h.<br />

Chlorine control valve (ATE) C 7700<br />

Modular disinfection<br />

Chlorinators C 2525 and C 2700 follow a clear<br />

modular structure. Whether we are talking of a<br />

compact unit with all functions integrated in a freestanding<br />

cabinet or of functional modules for your<br />

individual installation setup – a reliable vacuum<br />

system will always be at your disposal. Operational<br />

range up to 25 and 200 kg Cl 2 /h, respectively.<br />

Full vaccum<br />

chlorinator C 2525<br />

Dosing without any break<br />

Would you prefer an automatic system? In this case<br />

C 7520 and C 7522 are just the right devices for<br />

you: automatic changeover valves for uninterruptable<br />

chlorine gas supply. Microprocessor-controlled and<br />

motor-driven. Equipped with relay contacts for remote<br />

monitoring.<br />

C 7522: vacuum version up to 100 kg Cl 2 /h<br />

C 7520: pressure version up to 200 kg Cl 2 /h<br />

Automatic changeover valve C 7522<br />

11

Measuring and control technology<br />

Important values definitely under control<br />

Totally universal<br />

Having everything under control at just one glance<br />

All at a glance<br />

Lutz-Jesco controllers can be used in a variety of<br />

applications as they have been designed as universal<br />

controllers. They are mainly used in water treatment.<br />

Do you prefer technology of the latest generation?<br />

The bus-capable TOPAX DX controller can be<br />

adapted to your specific requirements by activating<br />

various additional features; it can even be upgraded<br />

to an integrated gas warning device. TOPAX can<br />

be connected to the PC-supported process control<br />

system TopView – for up to 15 controllers of the<br />

TOPAX family: TOPAX DX, TOPAX DE and<br />

TOPAX L. TOPAX controllers can be fitted to<br />

control the free chlorine concentration, pH value,<br />

redox and hydrogen peroxide / chlorine dioxide<br />

concentration. During automatic operation the<br />

most important reference variables can be<br />

displayed just by pressing a key.<br />

The future depends on communication: The TOPAX computer software TopView<br />

allows to control networked TOPAX systems via a PC – and thus the remote<br />

monitoring and setting of the controllers. Furthermore central recording of the<br />

measured values is possible. The configuration of TopView totally complies<br />

with your requests as the program is available for different performance levels.<br />

In short<br />

TOPAX DX<br />

• Time-controlled dosing<br />

• Large, clearly arranged displays<br />

• Can be networked<br />

• Available in many different languages<br />

• Gas warning devices can be integrated<br />

TopView<br />

• Available for all modern operating systems<br />

• Server/client possibilities<br />

• Can be networked<br />

• Available in many different languages<br />

TOPAX DX<br />

12

Systematic measurement<br />

Water and chlorine sampling stations<br />

Convincing technology<br />

Automatic measuring and control systems ensure<br />

the right water quality in modern water treatment.<br />

All required functional elements are mounted on the<br />

sampling stations ready for connection. Due to the<br />

great variety of our products we are able to supply<br />

the appropriate sampling station for each application.<br />

The complete solution<br />

Measure and control all parameters required to<br />

be recorded online – even combined chlorine:<br />

The DCM01 sampling station is fitted with the<br />

latest measuring and electronic equipment, for<br />

maximum operational convenience. Installation<br />

becomes easy because of the premounted measuring<br />

components. The innovative system includes almost<br />

maintenance-free sensors and a self-monitoring<br />

facility.<br />

Chlorine sampling station DCM01<br />

13

Chemical centrifugal pumps<br />

For industrial piping construction<br />

Tradition creates innovation<br />

Chemical centrifugal pumps for many possible fields of application<br />

Many decades of experience are incorporated in the<br />

centrifugal pumps from Lutz-Jesco. Special varnish<br />

layers and highly resistant materials guarantee highest<br />

reliability and long service life, even with most<br />

aggressive media. The product program includes<br />

motor pump units as well as standard pumps<br />

for many possible fields of application.<br />

Clear advantages<br />

The chemical centrifugal pumps from Lutz-Jesco have been developed<br />

particularly to be used for industrial applications and are thus especially<br />

sturdy and have a long service life – also in the case of most aggressive<br />

media and high-duty operation.<br />

In short<br />

• Corrosion-resistant PP/PVDF housing<br />

• Wetted-end parts of highly resistant materials<br />

• Motor and metallic parts are protected by a special varnish layer<br />

• Pump shaft of stainless steel and shaft protection sleeve<br />

• Reliability<br />

• Serviceability<br />

• DIN EN 22858/ISO 2858<br />

14

Chemical centrifugal pumps<br />

For highest requirements<br />

Universal<br />

The normal-priming chemical motor pump units<br />

MB with horizontal axis are designed particularly for<br />

low-viscosity, acidic and alkaline solutions with a<br />

low solid matter content. The head assembly of the<br />

single-stage pumps consists of high-quality plastic<br />

material and a hydraulically efficient spiral casing.<br />

Chemical motor pump units MB<br />

For highest requirements<br />

Chemical motor pump units BN are single-stage,<br />

normal-priming pumps with horizontal axis. They<br />

are supplied completely with motor for a fast and<br />

easy installation into the piping system. Suitable for<br />

capacities of up to 100 m 3 /h.<br />

Chemical motor pump units BN<br />

Smart setup<br />

Chemical standard pumps are single-stage,<br />

single-flow and normal-priming centrifugal pumps<br />

with spiral casing. Due to their modular structure<br />

the bearing support can be removed without having<br />

to dismantle the piping connections and the motor.<br />

Smooth and vibration-free operation because of the<br />

sturdy construction. For capacities of up to<br />

450 m 3 /h.<br />

Chemical standard pump N<br />

15

The right solution for professional dosing technology<br />

Dosing pumps<br />

Accessories<br />

Chlorination<br />

Measuring and control technology<br />

Centrifugal pumps<br />

Überreicht durch:<br />

Lutz-Jesco GmbH<br />

Am Bostelberge 19<br />

30900 Wedemark<br />

Germany<br />

Hungary<br />

Lutz-Jesco Üzletág<br />

Vasvári P. u. 9.<br />

9024 Györ<br />

Hungary<br />

Austria<br />

Lutz-Jesco GmbH<br />

Aredstraße 29/212<br />

2544 Leobersdorf<br />

Austria<br />

Netherlands<br />

Lutz-Jesco Nederland B.V.<br />

Nijverheidstraat 14 C<br />

2984 AH Ridderkerk<br />

Netherlands<br />

Tel.: +49 5130 58020<br />

Fax: +49 5130 580268<br />

E-Mail: info@jesco.de<br />

Internet: www.jesco.de<br />

Tel.: +36 96 523046<br />

Fax: +36 96 523047<br />

E-Mail: s.dudas@lutz-jesco.hu<br />

Internet: www.lutz-jesco.hu<br />

Tel.: +43 2256 62180<br />

Fax: +43 2256 6218062<br />

E-Mail: info@lutz-jesco.at<br />

Internet: www.lutz-jesco.at<br />

Tel.: +31 180 499460<br />

Fax: +31 180 497516<br />

E-Mail: info@lutz-jesco.nl<br />

Internet: www.lutz-jesco.nl<br />

<strong>P0001E</strong>-V04 / Subject to technical changes<br />

Copyright 04.2007 by Lutz-Jesco GmbH<br />

Great Britain<br />

Lutz-JESCO (GB) Ltd.<br />

Gateway Estate<br />

West Midlands Freeport<br />

Great Britian<br />

Tel.: +44 121 782 2662<br />

Fax: +44 121 782 2680<br />

E-Mail: summers@jesco.de<br />

Internet: www.jesco.co.uk<br />

USA<br />

Lutz-JESCO America Corp.<br />

55 Bermar Park<br />

Rochester, N.Y. 14624<br />

USA<br />

Tel.: +1 585 426-0990<br />

Fax: +1 585 426-4025<br />

E-Mail: mail@jescoamerica.com<br />

Internet: www.jescoamerica.com<br />

East Asia<br />

Lutz-Jesco<br />

East Asia Sdn Bhd<br />

18, Jalan TPJ 9<br />

Taman Perindustrian Jaya<br />

47200 Petaling Jaya<br />

Malaysia<br />

Tel.: +603 7845 4812<br />

Fax: +603 7845 8413<br />

E-Mail: info@lutz-jescoasia.com<br />

Middle East<br />

Lutz-Jesco GmbH<br />

Office L1-43<br />

P.O. Box 9614<br />

SAIF-Free Zone Center<br />

Sharjah<br />

UAE<br />

Tel.: +971 6 5572205<br />

Fax: +971 6 5572230<br />

E-Mail: kudchikar@jesco.de