Nontechnical Guide to Petroleum Geology, Exploration

Nontechnical Guide to Petroleum Geology, Exploration

Nontechnical Guide to Petroleum Geology, Exploration

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

• Review of reservoir inflow characterization and modeling <strong>to</strong>ols: inflow performance relationships;<br />

numerical vs. analytical modeling; steady-state, pseudo steady-state and transient reservoir flow.<br />

• Review of multiphase flow modeling in wellbores, risers and flowlines: empirical vs. mechanistic models;<br />

nodal analysis; steady-state flow models vs. transient flow models; tuning of multiphase flow models; flow<br />

assurance issues (i.e. hydrates, asphaltenes, waxes, scales).<br />

• Choke valves: the function of production choke valves; empirical vs. mechanistic models; critical and<br />

subcritical flow; the use of choke valves <strong>to</strong> handle back-pressure effects along the production system.<br />

• Surface facilities: production and test separa<strong>to</strong>rs; treatment facilities; export lines; points of sale.<br />

• Production optimization techniques: solutions <strong>to</strong> boost oil production; liquid unloading techniques in gas<br />

wells; downhole and seabed water separation.<br />

• Diagnosis of systems performance: real-time moni<strong>to</strong>ring; production logging; multiphase flow metering;<br />

downhole moni<strong>to</strong>ring<br />

• Production Allocation: commingling of produced hydrocarbons from different fields through the same<br />

export facilities; well testing; fiscal allocation; metering points; metering accuracy; “value adjustment” for<br />

hydrocarbons of different quality.<br />

• Linking the reservoir, the near-wellbore, the wellbore and the surface facilities: the concept of boundary<br />

conditions in steady-state flow and transient flow; the “near-wellbore” region; limitations of current<br />

modeling <strong>to</strong>ols.<br />

• Planning short-, medium and long-term optimization of field management: water and gas shut-offs; reperforation;<br />

stimulation; re-completion; debottlenecking of <strong>to</strong>psides facilities; handling transient flow<br />

situations in the system; issues around the chosen export route; offshore vs. onshore scenarios.<br />

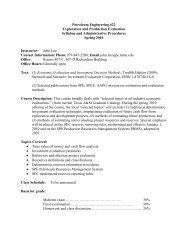

Class Schedule: 2 75-min lecture sessions per week<br />

Method of Evaluation:<br />

Homework 20%<br />

Mid-term Examination 35%<br />

Final Project 45%<br />

Total 100%<br />

Contributions <strong>to</strong> Professional Component:<br />

• <strong>Petroleum</strong> Enginnering: provides students with a clear understanding of the importance of an integrated<br />

approach <strong>to</strong> production enhancement (from reservoir <strong>to</strong> surface, through the wells and the production<br />

network), which is fundamental in modern petroleum engineering.<br />

• General Education: provides students with experience working in teams, and develops analysis and<br />

presentation skills.<br />

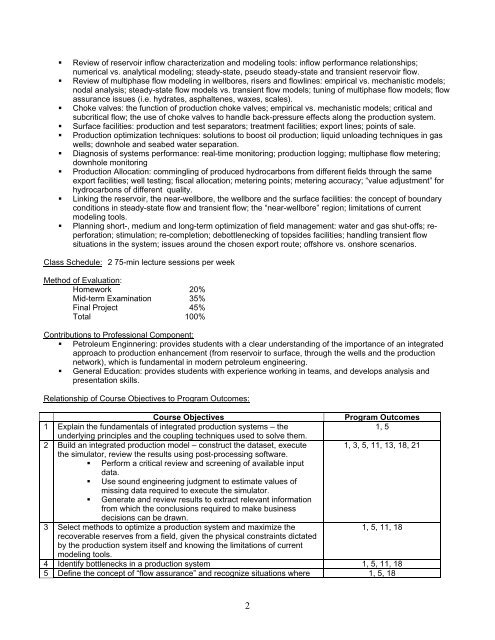

Relationship of Course Objectives <strong>to</strong> Program Outcomes:<br />

Course Objectives<br />

Program Outcomes<br />

1 Explain the fundamentals of integrated production systems – the<br />

1, 5<br />

underlying principles and the coupling techniques used <strong>to</strong> solve them.<br />

2 Build an integrated production model – construct the dataset, execute 1, 3, 5, 11, 13, 18, 21<br />

the simula<strong>to</strong>r, review the results using post-processing software.<br />

• Perform a critical review and screening of available input<br />

data.<br />

• Use sound engineering judgment <strong>to</strong> estimate values of<br />

missing data required <strong>to</strong> execute the simula<strong>to</strong>r.<br />

• Generate and review results <strong>to</strong> extract relevant information<br />

from which the conclusions required <strong>to</strong> make business<br />

decisions can be drawn.<br />

3 Select methods <strong>to</strong> optimize a production system and maximize the<br />

1, 5, 11, 18<br />

recoverable reserves from a field, given the physical constraints dictated<br />

by the production system itself and knowing the limitations of current<br />

modeling <strong>to</strong>ols.<br />

4 Identify bottlenecks in a production system 1, 5, 11, 18<br />

5 Define the concept of “flow assurance” and recognize situations where 1, 5, 18<br />

2