Download the July/August 2003 Issue in PDF format - Gear ...

Download the July/August 2003 Issue in PDF format - Gear ...

Download the July/August 2003 Issue in PDF format - Gear ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>in</strong>g methods of hobb<strong>in</strong>g clustergears with <strong>the</strong><br />

shortest neck, i.e, cluster gears with l=lmill '<br />

In <strong>the</strong> paper, notation of parameters recommended<br />

by ANSYAGMA (Ref. I) is used.<br />

Literary Survey<br />

A few directions of hob feed are recognized.<br />

Downward feed direction (<strong>in</strong> conventional gear<br />

bobb<strong>in</strong>g) and upward feed direction (<strong>in</strong> climb<br />

gear bobb<strong>in</strong>g) are mostly used.<br />

The reduction<br />

of total hob travel distance<br />

leads to a reduction of total gear bobb<strong>in</strong>g time<br />

and is widely recognized. The parameters IQfII<br />

gear to be mach<strong>in</strong>ed are given anda gear manufacturer<br />

cannot change <strong>the</strong>m. <strong>Gear</strong> manufacturers<br />

cannot reduce gear face width. A total hob travel<br />

distance can. be reduced if one gets to know <strong>the</strong><br />

shortest allowedlength of approach distance and<br />

<strong>the</strong> shortest allowed hob idle distance, In this<br />

paper, <strong>the</strong> shortest allowed hob idle distance is<br />

considered ..<br />

A hob rotates about its axis (Fig. 3), with a<br />

constant angular velocity w h<br />

• Simultaneously, <strong>the</strong><br />

hob moves along <strong>the</strong> work axis <strong>in</strong> <strong>the</strong> feed direction<br />

(or <strong>in</strong> <strong>the</strong> opposite direction <strong>in</strong> a conventiona]<br />

gear hobb<strong>in</strong>g operation).<br />

Cutter total travel distance AD (Fig .. 3) is<br />

equal to <strong>the</strong> sum of <strong>the</strong> hob approach distance<br />

AB, [ace width Be,. and hob idle distance (or hob<br />

overrun) CD.<br />

The hob approach is <strong>the</strong> distance that <strong>the</strong> hob<br />

has to travel parallel to <strong>the</strong> gear axis, frOID<strong>the</strong><br />

po<strong>in</strong>t of <strong>in</strong>itial contact between <strong>the</strong> hob and <strong>the</strong><br />

po<strong>in</strong>t where center distance reaches <strong>the</strong> first gear<br />

face (at <strong>the</strong> po<strong>in</strong>t B). TIle hob approach distance<br />

can be computed by know<strong>in</strong>g <strong>the</strong> appropriate formula,<br />

which is available <strong>in</strong> Reference 4.<br />

The gear [ace width is <strong>in</strong>dicated on <strong>the</strong> part<br />

pr<strong>in</strong>t.<br />

Its length cannot be changed by gear manufacturers.<br />

The hob idle di lance, a distance required to<br />

complete generat<strong>in</strong>g of <strong>the</strong> entice set of gear teeth,<br />

is <strong>the</strong> l<strong>in</strong>ear hob carriage travel beyond <strong>the</strong> second<br />

gear face C.<br />

There is no complete understand<strong>in</strong>g of what<br />

<strong>the</strong> hob idle distance exactly is and how to compute<br />

it m<strong>in</strong>imally, allow<strong>in</strong>g length for hobb<strong>in</strong>g a given<br />

cluster gear. For example, <strong>in</strong> accordance with recommendations<br />

given by hob manufacturer FEllE<br />

GmbH: "No idle distance, except for a afety<br />

allowance, is required for straight teeth" (Ref. 4).<br />

lmpact of <strong>the</strong> Hob Idle Distance OD Axial Size<br />

of a Robbed Cluster <strong>Gear</strong><br />

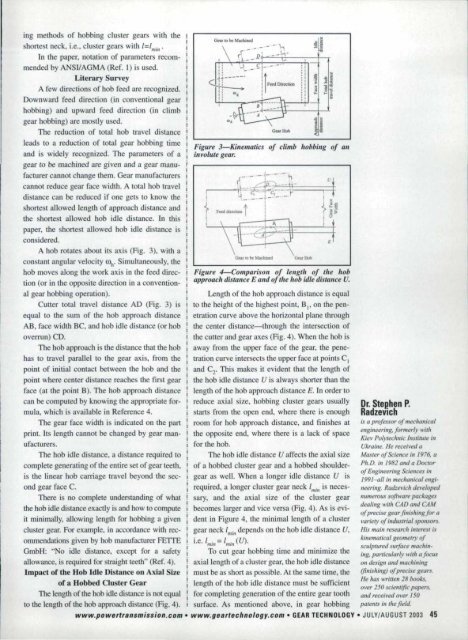

The length.of <strong>the</strong> hob idle distance is not equal<br />

to <strong>the</strong> length of <strong>the</strong> hob approach distance (Fig. 4).<br />

www.p.ow.erl.ran.smiss.ion·.com<br />

Figure 3-K<strong>in</strong>elllatics of climb hoM<strong>in</strong>g of all<br />

<strong>in</strong>volute gear.<br />

Figure 4-Comparisoll. of length of tile hob<br />

approach distance E CllId of <strong>the</strong> hob idle distallce U.<br />

Length of <strong>the</strong> hob approach distance is equal<br />

to <strong>the</strong> height of <strong>the</strong> highest po<strong>in</strong>t, BI' on <strong>the</strong> penetration<br />

curve above <strong>the</strong> horizontal plane through<br />

<strong>the</strong> center distance-through <strong>the</strong> <strong>in</strong>tersection of<br />

<strong>the</strong> cutter and gear axes (Fig. 4). When <strong>the</strong> hob is<br />

away from <strong>the</strong> upper face of <strong>the</strong> gear, <strong>the</strong> penetrationcurve<br />

<strong>in</strong>tersects <strong>the</strong> upper face at po<strong>in</strong>ts C[<br />

and C 2<br />

• This makes it evident that <strong>the</strong> length of<br />

<strong>the</strong> hob idle distance U is always shorter than <strong>the</strong><br />

length of <strong>the</strong> bob approach distance E. In order to<br />

reduce axial size, bobb<strong>in</strong>g cluster gears usually<br />

starts from <strong>the</strong> open end, where <strong>the</strong>re is enough<br />

room for hob approach distance, and f<strong>in</strong>ishes at<br />

~D,r"Stel!hen P.<br />

!R.adzevich<br />

is a professor a/mechanical<br />

eng<strong>in</strong>eer<strong>in</strong>g, formerly with<br />

<strong>the</strong> opposite end, where <strong>the</strong>re is a lack of space<br />

Kiev Polyiechnic Institute <strong>in</strong><br />

for <strong>the</strong> hob.<br />

Ukra<strong>in</strong>e. He received a<br />

The hob idle distance U affects <strong>the</strong> axial size Master 0/ Science <strong>in</strong> 1976, a<br />

PIr.D. <strong>in</strong> ./982<br />

of a hobbed cluster gear and<br />

and a Doctor<br />

8. hobbed shouldergear<br />

as well, When a longer idle distance U is<br />

ofEng<strong>in</strong>eer<strong>in</strong>g Sciences <strong>in</strong><br />

1991-a1l <strong>in</strong> mechanical eng<strong>in</strong>eer<strong>in</strong>g.<br />

required, a longer cluster gear neck {",In is necessary,<br />

Radzevich developed<br />

and jhe axial size of <strong>the</strong> cluster gear numerous software packages<br />

deal<strong>in</strong>g with CAD ana CAM<br />

becomes larger and vice versa (Fig. 4). As is evident<br />

<strong>in</strong> Figure 4, <strong>the</strong> m<strong>in</strong>imal length of a cluster variety 0/ <strong>in</strong>dus/rial sponsors.<br />

a/precise gear f<strong>in</strong>ish<strong>in</strong>g for a<br />

gear neck {mill depends on <strong>the</strong> hob idle distance U, His ma<strong>in</strong> research <strong>in</strong>terest is<br />

k<strong>in</strong>ematical geometry 0/<br />

i.e. i"';11 = i"'<strong>in</strong> (U).<br />

sculptured surface mach<strong>in</strong><strong>in</strong>g.<br />

particularly with a focus<br />

To cut gear hobb<strong>in</strong>g time and m<strong>in</strong>imize <strong>the</strong><br />

axial length of a cluster gear, <strong>the</strong> hob idle distance Ofl design and mach<strong>in</strong><strong>in</strong>g<br />

must be as short as possible. At <strong>the</strong> same time, <strong>the</strong> (f<strong>in</strong>ish<strong>in</strong>g) of'precise gears.<br />

length of <strong>the</strong> hob idle distance must be sufficient<br />

He has written 28 books,<br />

over 250 scientific papers.<br />

tor complet<strong>in</strong>g generation of <strong>the</strong> entire gear tooth and received over 150<br />

surface. As mentioned above, <strong>in</strong> gear hobb<strong>in</strong>g patents <strong>in</strong> <strong>the</strong> field.<br />

www ..gea.rtechnology ..com. IGEA!RIECiHN,lJlOGY • JUlY/AUGUSr <strong>2003</strong> 45