Chairside Magazine Volume 2, Issue 1 - Glidewell Dental Labs

Chairside Magazine Volume 2, Issue 1 - Glidewell Dental Labs

Chairside Magazine Volume 2, Issue 1 - Glidewell Dental Labs

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

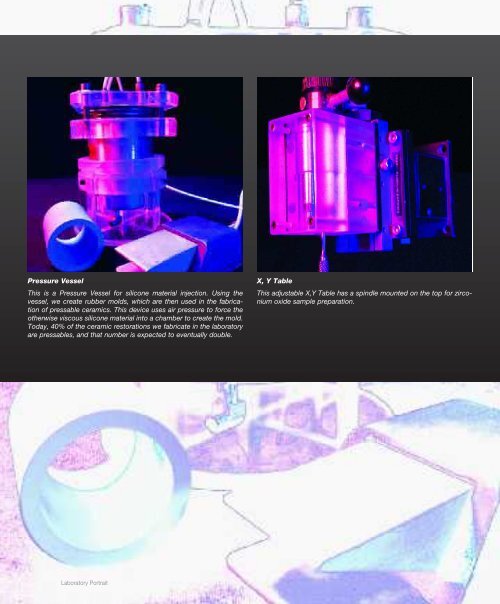

Pressure Vessel<br />

This is a Pressure Vessel for silicone material injection. Using the<br />

vessel, we create rubber molds, which are then used in the fabrication<br />

of pressable ceramics. This device uses air pressure to force the<br />

otherwise viscous silicone material into a chamber to create the mold.<br />

Today, 40% of the ceramic restorations we fabricate in the laboratory<br />

are pressables, and that number is expected to eventually double.<br />

X, Y Table<br />

This adjustable X,Y Table has a spindle mounted on the top for zirconium<br />

oxide sample preparation.<br />

military engineering training combined to make him an integral part of one of the dental lab industry’s<br />

most advanced commercial R&D departments.<br />

One of the first episodes that brought Mikhail’s talents to Jim <strong>Glidewell</strong>’s personal attention was the failure<br />

of a critical $30,000 piece of intricate equipment from Germany that would have slowed production of<br />

restorations to a crawl, something that would have been unacceptable to <strong>Glidewell</strong>, its customers and to<br />

countless patients around the country.<br />

The problem was that the machine’s manufacturer in Germany would take two weeks to get a technician<br />

to California with the proper replacement parts. Not good. Enter Mr. Tkachev with an offer to take<br />

the thing apart, figure out what makes it tick and do whatever it takes to get it back online. Needless<br />

to say, there were those who questioned the advisability of such a course of action, but Mike knew he<br />

could do it-all those years of military training weren’t wasted on him and Jim <strong>Glidewell</strong> opted to give him<br />

the chance.<br />

Mike worked into the night, eventually isolating the problem to a certain sector of the main motherboard,<br />

which he took home to test with his own special electronic diagnostic equipment. (Best not to ask.) By 4<br />

a.m. he’d tracked the problem to a single chip that he was sure was the culprit.<br />

When businesses opened later that morning, he rushed to an electrical supply shop to get a replacement<br />

chip. “No such thing” he was told by the man behind the counter. “Not in this country.” Turns out he was<br />

right. There was no U.S. equivalent for the German chip used in the machine.<br />

Not to be deterred, Mikhail asked for the catalog to leaf through himself to find something, anything, that<br />

he could use to replace the faulty chip. Finally he found an item that was close enough in function and<br />

size to the original that with some ingenuity and a hot soldering iron he could make it work, whether it<br />

wanted to or not.<br />

Sure enough, before noon that very day, just as <strong>Glidewell</strong> managers were filing into a meeting where<br />

they’d decide what to do about the calamitous equipment failure, Mikhail was able to send the message<br />

up to the brass: ”The machine is put back together, and it works. It works!”<br />

Mikhail has gone on to devise dozens of ingenious solutions to problems, and new ways to accomplish<br />

old tasks in smarter, more efficient and more economical ways. He’s an important reason <strong>Glidewell</strong> is the<br />

competitive powerhouse it is, constantly offering its customers new products and better prices.<br />

One such example is the magnetic articulator system marketed by <strong>Glidewell</strong> Direct. It’s an elegantly simple<br />

solution for dental technicians’ desire to hold impressions securely in place and then remove them quickly,<br />

without having to make a huge investment in a competing system. Yes, it was Jim <strong>Glidewell</strong>’s idea to<br />

develop such a tool, but it’s Mikhail’s creation, right down to the details of tooling and die-casting.<br />

Of course, being the gentleman he is, Mikhail breaks into his typical bright-eyed, boyish grin when<br />

he discusses the articulator and credits his co-workers and especially Wolfgang Friebauer, the head of<br />

<strong>Glidewell</strong>’s R&D department, for bringing it into being. He even asked that <strong>Chairside</strong> deflect credit to his<br />

machinist, Viktor Khivrenko.<br />

Need proof of the Tkachevs’ success in America? Both of their children graduated college at the age of<br />

18. Daughter Alona is now studying nursing at Long Beach State, and son Sergei, who earned a BA from<br />

UCLA at age 21, works at KPMG and is halfway though his CPA exams.<br />

Meanwhile, Vladikavkas remains a small but technically advanced town in the Caucasus Mountains, now<br />

home to the Polymer Research Institute of Electronic Materials, a place Mikhail may have found employment<br />

had he stayed. And had the secret police approved.<br />

Laboratory Portrait<br />

Laboratory Portrait