Morningside Report and Summary Here - KiwiRail

Morningside Report and Summary Here - KiwiRail

Morningside Report and Summary Here - KiwiRail

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

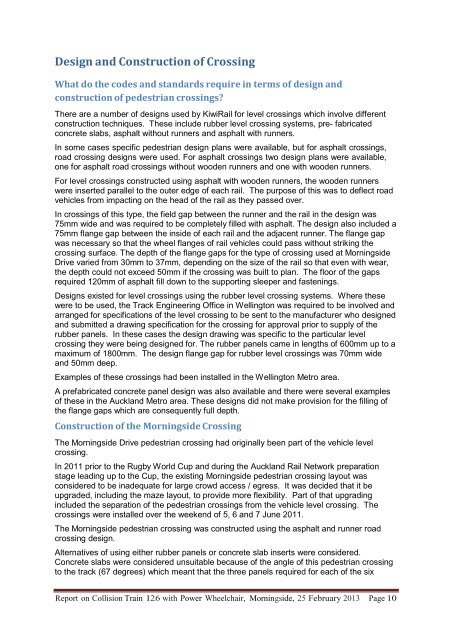

Design <strong>and</strong> Construction of Crossing<br />

What do the codes <strong>and</strong> st<strong>and</strong>ards require in terms of design <strong>and</strong><br />

construction of pedestrian crossings?<br />

There are a number of designs used by <strong>KiwiRail</strong> for level crossings which involve different<br />

construction techniques. These include rubber level crossing systems, pre- fabricated<br />

concrete slabs, asphalt without runners <strong>and</strong> asphalt with runners.<br />

In some cases specific pedestrian design plans were available, but for asphalt crossings,<br />

road crossing designs were used. For asphalt crossings two design plans were available,<br />

one for asphalt road crossings without wooden runners <strong>and</strong> one with wooden runners.<br />

For level crossings constructed using asphalt with wooden runners, the wooden runners<br />

were inserted parallel to the outer edge of each rail. The purpose of this was to deflect road<br />

vehicles from impacting on the head of the rail as they passed over.<br />

In crossings of this type, the field gap between the runner <strong>and</strong> the rail in the design was<br />

75mm wide <strong>and</strong> was required to be completely filled with asphalt. The design also included a<br />

75mm flange gap between the inside of each rail <strong>and</strong> the adjacent runner. The flange gap<br />

was necessary so that the wheel flanges of rail vehicles could pass without striking the<br />

crossing surface. The depth of the flange gaps for the type of crossing used at <strong>Morningside</strong><br />

Drive varied from 30mm to 37mm, depending on the size of the rail so that even with wear,<br />

the depth could not exceed 50mm if the crossing was built to plan. The floor of the gaps<br />

required 120mm of asphalt fill down to the supporting sleeper <strong>and</strong> fastenings.<br />

Designs existed for level crossings using the rubber level crossing systems. Where these<br />

were to be used, the Track Engineering Office in Wellington was required to be involved <strong>and</strong><br />

arranged for specifications of the level crossing to be sent to the manufacturer who designed<br />

<strong>and</strong> submitted a drawing specification for the crossing for approval prior to supply of the<br />

rubber panels. In these cases the design drawing was specific to the particular level<br />

crossing they were being designed for. The rubber panels came in lengths of 600mm up to a<br />

maximum of 1800mm. The design flange gap for rubber level crossings was 70mm wide<br />

<strong>and</strong> 50mm deep.<br />

Examples of these crossings had been installed in the Wellington Metro area.<br />

A prefabricated concrete panel design was also available <strong>and</strong> there were several examples<br />

of these in the Auckl<strong>and</strong> Metro area. These designs did not make provision for the filling of<br />

the flange gaps which are consequently full depth.<br />

Construction of the <strong>Morningside</strong> Crossing<br />

The <strong>Morningside</strong> Drive pedestrian crossing had originally been part of the vehicle level<br />

crossing.<br />

In 2011 prior to the Rugby World Cup <strong>and</strong> during the Auckl<strong>and</strong> Rail Network preparation<br />

stage leading up to the Cup, the existing <strong>Morningside</strong> pedestrian crossing layout was<br />

considered to be inadequate for large crowd access / egress. It was decided that it be<br />

upgraded, including the maze layout, to provide more flexibility. Part of that upgrading<br />

included the separation of the pedestrian crossings from the vehicle level crossing. The<br />

crossings were installed over the weekend of 5, 6 <strong>and</strong> 7 June 2011.<br />

The <strong>Morningside</strong> pedestrian crossing was constructed using the asphalt <strong>and</strong> runner road<br />

crossing design.<br />

Alternatives of using either rubber panels or concrete slab inserts were considered.<br />

Concrete slabs were considered unsuitable because of the angle of this pedestrian crossing<br />

to the track (67 degrees) which meant that the three panels required for each of the six<br />

<strong>Report</strong> on Collision Train 126 with Power Wheelchair, <strong>Morningside</strong>, 25 February 2013 Page 10