You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

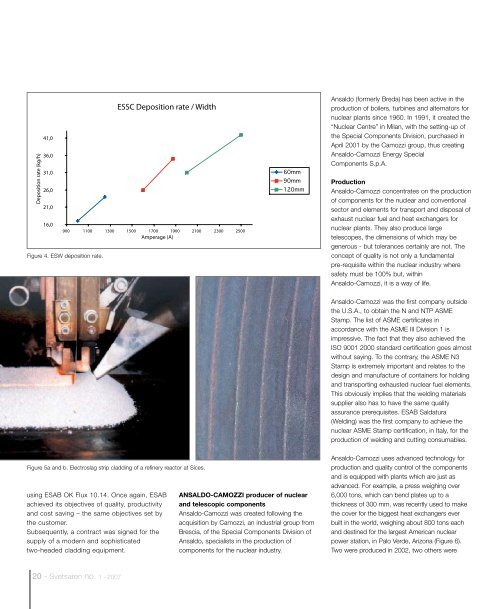

Deposition rate (kg/h)<br />

ESSC Deposition rate / Width<br />

41,0<br />

36,0<br />

31,0<br />

26,0<br />

21,0<br />

16,0<br />

900 1100 1300 1500 1700 1900 2100 2300 2500<br />

Amperage (A)<br />

Figure 4. ESW deposition rate.<br />

60mm<br />

90mm<br />

120mm<br />

Ansaldo (formerly Breda) has been active in the<br />

production of boilers, turbines and alternators for<br />

nuclear plants since 1960. In 1991, it created the<br />

“Nuclear Centre” in Milan, with the setting-up of<br />

the Special Components Division, purchased in<br />

April 2001 by the Camozzi group, thus creating<br />

Ansaldo-Camozzi Energy Special<br />

Components S.p.A.<br />

Production<br />

Ansaldo-Camozzi concentrates on the production<br />

of components for the nuclear and conventional<br />

sector and elements for transport and disposal of<br />

exhaust nuclear fuel and heat exchangers for<br />

nuclear plants. They also produce large<br />

telescopes, the dimensions of which may be<br />

generous - but tolerances certainly are not. The<br />

concept of quality is not only a fundamental<br />

pre-requisite within the nuclear industry where<br />

safety must be 100% but, within<br />

Ansaldo-Camozzi, it is a way of life.<br />

Ansaldo-Camozzi was the first company outside<br />

the U.S.A., to obtain the N and NTP ASME<br />

Stamp. The list of ASME certificates in<br />

accordance with the ASME III Division 1 is<br />

impressive. The fact that they also achieved the<br />

ISO 9001 2000 standard certification goes almost<br />

without saying. To the contrary, the ASME N3<br />

Stamp is extremely important and relates to the<br />

design and manufacture of containers for holding<br />

and transporting exhausted nuclear fuel elements.<br />

This obviously implies that the welding materials<br />

supplier also has to have the same quality<br />

assurance prerequisites. ESAB Saldatura<br />

(Welding) was the first company to achieve the<br />

nuclear ASME Stamp certification, in Italy, for the<br />

production of welding and cutting consumables.<br />

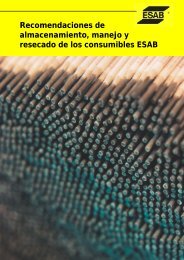

Figure 5a and b. Electroslag strip cladding of a refinery reactor at Sices.<br />

using ESAB OK Flux 10.14. Once again, ESAB<br />

achieved its objectives of quality, productivity<br />

and cost saving – the same objectives set by<br />

the customer.<br />

Subsequently, a contract was signed for the<br />

supply of a modern and sophisticated<br />

two-headed cladding equipment.<br />

ANSALDO-CAMOZZI producer of nuclear<br />

and telescopic components<br />

Ansaldo-Camozzi was created following the<br />

acquisition by Camozzi, an industrial group from<br />

Brescia, of the Special Components Division of<br />

Ansaldo, specialists in the production of<br />

components for the nuclear industry.<br />

Ansaldo-Camozzi uses advanced technology for<br />

production and quality control of the components<br />

and is equipped with plants which are just as<br />

advanced. For example, a press weighing over<br />

6,000 tons, which can bend plates up to a<br />

thickness of 300 mm, was recently used to make<br />

the cover for the biggest heat exchangers ever<br />

built in the world, weighing about 800 tons each<br />

and destined for the largest American nuclear<br />

power station, in Palo Verde, Arizona (Figure 6).<br />

Two were produced in 2002, two others were<br />

20 - <strong>Svetsaren</strong> no. 1 - <strong>2007</strong>