Master Mag Templet - Frank's International, Inc.

Master Mag Templet - Frank's International, Inc.

Master Mag Templet - Frank's International, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

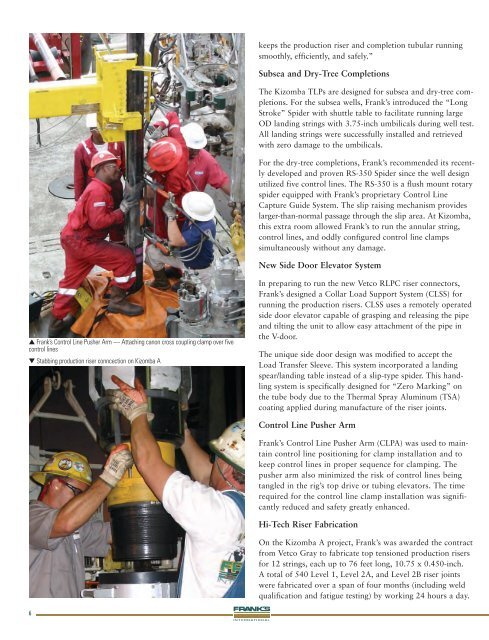

▲ Frank’s Control Line Pusher Arm — Attaching canon cross coupling clamp over five<br />

control lines<br />

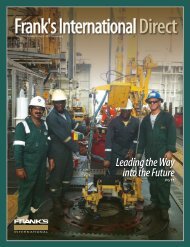

▼ Stabbing production riser conncection on Kizomba A<br />

6<br />

keeps the production riser and completion tubular running<br />

smoothly, efficiently, and safely.”<br />

Subsea and Dry-Tree Completions<br />

The Kizomba TLPs are designed for subsea and dry-tree completions.<br />

For the subsea wells, Frank’s introduced the “Long<br />

Stroke” Spider with shuttle table to facilitate running large<br />

OD landing strings with 3.75-inch umbilicals during well test.<br />

All landing strings were successfully installed and retrieved<br />

with zero damage to the umbilicals.<br />

For the dry-tree completions, Frank’s recommended its recently<br />

developed and proven RS-350 Spider since the well design<br />

utilized five control lines. The RS-350 is a flush mount rotary<br />

spider equipped with Frank’s proprietary Control Line<br />

Capture Guide System. The slip raising mechanism provides<br />

larger-than-normal passage through the slip area. At Kizomba,<br />

this extra room allowed Frank’s to run the annular string,<br />

control lines, and oddly configured control line clamps<br />

simultaneously without any damage.<br />

New Side Door Elevator System<br />

In preparing to run the new Vetco RLPC riser connectors,<br />

Frank’s designed a Collar Load Support System (CLSS) for<br />

running the production risers. CLSS uses a remotely operated<br />

side door elevator capable of grasping and releasing the pipe<br />

and tilting the unit to allow easy attachment of the pipe in<br />

the V-door.<br />

The unique side door design was modified to accept the<br />

Load Transfer Sleeve. This system incorporated a landing<br />

spear/landing table instead of a slip-type spider. This handling<br />

system is specifically designed for “Zero Marking” on<br />

the tube body due to the Thermal Spray Aluminum (TSA)<br />

coating applied during manufacture of the riser joints.<br />

Control Line Pusher Arm<br />

Frank’s Control Line Pusher Arm (CLPA) was used to maintain<br />

control line positioning for clamp installation and to<br />

keep control lines in proper sequence for clamping. The<br />

pusher arm also minimized the risk of control lines being<br />

tangled in the rig’s top drive or tubing elevators. The time<br />

required for the control line clamp installation was significantly<br />

reduced and safety greatly enhanced.<br />

Hi-Tech Riser Fabrication<br />

On the Kizomba A project, Frank’s was awarded the contract<br />

from Vetco Gray to fabricate top tensioned production risers<br />

for 12 strings, each up to 76 feet long, 10.75 x 0.450-inch.<br />

A total of 540 Level 1, Level 2A, and Level 2B riser joints<br />

were fabricated over a span of four months (including weld<br />

qualification and fatigue testing) by working 24 hours a day.