Modified Stock Gearing - Boston Gear

Modified Stock Gearing - Boston Gear

Modified Stock Gearing - Boston Gear

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

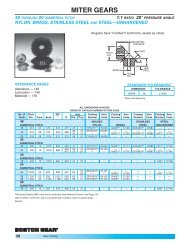

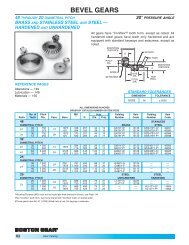

Miter & Bevel <strong>Gear</strong>s<br />

<strong>Boston</strong> stock miter and bevel gears are designed for transmission of power<br />

and/or motion between intersecting shafts at a right angle (90°). Miter gears are<br />

a special type of bevel gear designed to operate as pairs being identical in<br />

number of teeth and pitch (1 to 1 ratio only). Other <strong>Boston</strong> stock bevel gear sets<br />

are available with ratios from 1-1/2:1 to 6:1.<br />

All <strong>Boston</strong> standard stock bevels and miters are manufactured with a 20°<br />

pressure angle. These bevel gears are made in accordance with AGMA<br />

specifications for a long and short addendum system for gears and pinions,<br />

which serves to reduce the amount of pinion tooth undercut and to nearly<br />

equalize the strength and durability of the gear and pinion. <strong>Boston</strong> straight tooth<br />

bevel and miter gears have generated teeth with “Coniflex” ® tooth form, unless<br />

otherwise specified.<br />

INTERCHANGE<br />

<strong>Stock</strong> miter and bevel gears having identical diametral pitch, number of teeth<br />

and mounting distance (and spiral angle for spiral bevels) are interchangeable.<br />

SPIRAL VS. STRAIGHT TOOTH<br />

<strong>Boston</strong> standard stock straight bevel gears can be used for all applications<br />

requiring transmission of power and motion between intersecting shafts. <strong>Boston</strong><br />

standard stock spiral bevel gears have an overlapping tooth action which<br />

results in a smoother gear action, lower noise, and higher load capacity than a<br />

straight bevel of equal size.<br />

®Trademark of the Gleason Works.<br />

Selection Procedure<br />

Approximate horsepower ratings for selected sizes (number<br />

of teeth) at various operating speeds (RPM) are given for<br />

<strong>Boston</strong> standard stock Bevel and Miter gears.<br />

For straight tooth Miter gears, refer to Pages 80, 81.<br />

For straight tooth Bevel gears, refer to Page 82.<br />

For spiral tooth Miter gears, refer to Page 83.<br />

For spiral tooth Bevel gears, refer to Page 83.<br />

All ratings are based on normal operating conditions, that is:<br />

properly mounted and lubricated, carrying a smooth load for<br />

not more than 10 hours (Service Factor = 1.0). Refer to Table 1<br />

for service factors in other service conditions.<br />

1. Determine service factor.<br />

a. Using Application Classification Chart I, pages 323-324<br />

determine service factor or<br />

b. With knowledge of operating conditions and load<br />

classification, select service factor from Table 1.<br />

2. Determine Design Horsepower.<br />

Design HP = Application Load x Service Factor (Table 1)<br />

3. Select a gear set with horsepower capacity equal to (or<br />

greater than) design horsepower determined in Step 2.<br />

C<br />

TABLE 1<br />

Service<br />

Factor<br />

Operating Conditions<br />

.8 Uniform — not more than 15 minutes in 2 hours.<br />

Moderate Shock — not more than 15 minutes in 2 hours.<br />

1.0<br />

Uniform — not more than 10 hours per day.<br />

Moderate Shock — not more than 10 hours per day.<br />

1.25<br />

Uniform — more than 10 hours per day.<br />

Heavy Shock — not more than 15 minutes in 2 hours.<br />

1.50<br />

Moderate Shock — more than 10 hours per day.<br />

1.75 Heavy Shock — not more than 10 hours per day.<br />

2.0 Heavy Shock — more than 10 hours per day.<br />

Heavy shock loads and/or severe wear conditions may<br />

require the use of higher service factors. Consultation with<br />

factory is recommended in these applications.<br />

P-1930-BG 04/10 <strong>Boston</strong> <strong>Gear</strong> 800-825-6544 79