You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>MTU</strong> Brown<br />

0-17-28-62<br />

CMYK CMYK<br />

<strong>MTU</strong> Brown<br />

80% der Farbe<br />

60%<br />

CMYK<br />

<strong>MTU</strong> Blue <strong>MTU</strong> Blue<br />

60%<br />

50-25-0-10 80% der Farbe<br />

CMYK<br />

CMYK CMYK<br />

40%<br />

CMYK<br />

40%<br />

CMYK<br />

20%<br />

CMYK<br />

20%<br />

CMYK<br />

<strong>Energy</strong><br />

a vast amount of approval work,” he recalled.<br />

He was also impressed by the open and positive<br />

approach adopted by the team from <strong>MTU</strong> <strong>Onsite</strong><br />

<strong>Energy</strong>. "We always regarded each other as equals<br />

in our discussions and developed our ideas jointly.<br />

That was how the suggestion came about to<br />

replace the two large gensets with six smaller<br />

ones and build a gallery floor to accommodate the<br />

SCR systems for exhaust gas aftertreatment.”<br />

Cleaner, faster, more economical<br />

He reported proudly how cleanly and efficiently<br />

the units run. “With the new engines we have<br />

reduced the particulate emissions to a sixth of<br />

what they were, nitrogen oxides to a quarter<br />

and carbon monoxide to half the previous level<br />

per kilowatt-hour generated, and even lowered<br />

fuel consumption by 10% at the same time,”<br />

he recounted. The reason for those impressive<br />

figures are the modern engines with commonrail<br />

fuel injection and controlled SCR catalytic<br />

converters. The latter clean the exhaust by<br />

injecting urea into it. In the catalytic converter,<br />

the urea reacts with the nitrogen oxides to form<br />

the hamrless substances water and nitrogen.<br />

“These generator sets are inside the air pollution<br />

limits by a long way,” he stated with conviction.<br />

And with the power plant being right in the town<br />

of Fulda, it goes without saying that the emission<br />

levels have to be as low as possible. Because of<br />

that inner city location, ÜWAG also paid particular<br />

attention to reducing noise emission. Special<br />

soundproof walls allow almost no sound at all<br />

to escape to the outside when the engines are<br />

starting up and running.<br />

system installed. It allows the specialists at<br />

<strong>MTU</strong> <strong>Onsite</strong> <strong>Energy</strong> in Friedrichshafen to access<br />

the gensets and other components of the plant<br />

remotely and give advice on how to prevent or<br />

rectify faults.<br />

“Something special”<br />

The first three of six gensets went into operation<br />

in the power plant on December 23, 2011. Sven<br />

Kunkel remembers the period just before then<br />

very well. He and the whole team were under<br />

extreme pressure. Especially because at that<br />

time the plant had to be kept running constantly<br />

at 75%. “We were contractually obliged to<br />

supply electricity, we couldn’t shut down.” It<br />

was not until September 2012, when the local<br />

authorities in Fulda celebrated the inauguration<br />

of the power plant that Kunkel was finally able<br />

to relax. "The flexibility of this power plant meets<br />

the demands of the current market perfectly. It<br />

really is something special for a local authority<br />

supplier to have something like this," recalls<br />

the electrical engineer who is now also a diesel<br />

engine specialist.<br />

North Sea<br />

Netherlands<br />

Belgium<br />

Words: Lucie Maluck<br />

Pictures: Robert Hack<br />

Germany<br />

Fulda<br />

Italy<br />

To find out more, contact:<br />

Dietmar Witzigmann<br />

dietmar.witzigmann@mtu-online.de<br />

Tel. +49 7541 90-4841<br />

Berlin<br />

Austria<br />

Poland<br />

Czech<br />

Republic<br />

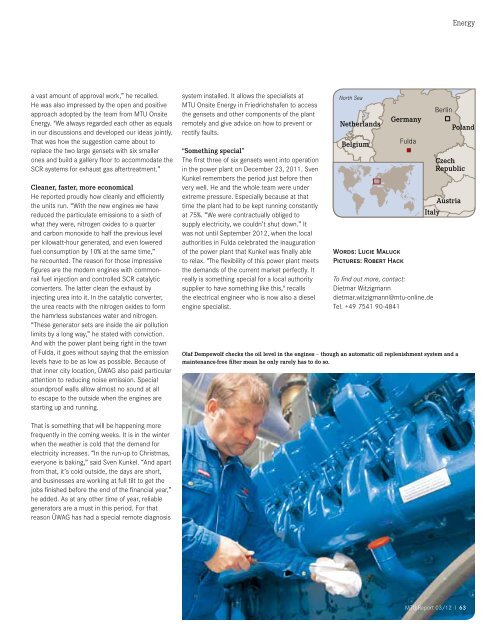

Olaf Dempewolf checks the oil level in the engines – though an automatic oil replenishment system and a<br />

maintenance-free filter mean he only rarely has to do so.<br />

That is something that will be happening more<br />

frequently in the coming weeks. It is in the winter<br />

when the weather is cold that the demand for<br />

electricity increases. “In the run-up to Christmas,<br />

everyone is baking,” said Sven Kunkel. “And apart<br />

from that, it’s cold outside, the days are short,<br />

and businesses are working at full tilt to get the<br />

jobs finished before the end of the financial year,”<br />

he added. As at any other time of year, reliable<br />

generators are a must in this period. For that<br />

reason ÜWAG has had a special remote diagnosis<br />

<strong>MTU</strong> Report 03/12 I 63

![Full power range of diesel generator sets [PDF] - MTU Onsite Energy](https://img.yumpu.com/28297693/1/190x253/full-power-range-of-diesel-generator-sets-pdf-mtu-onsite-energy.jpg?quality=85)