You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

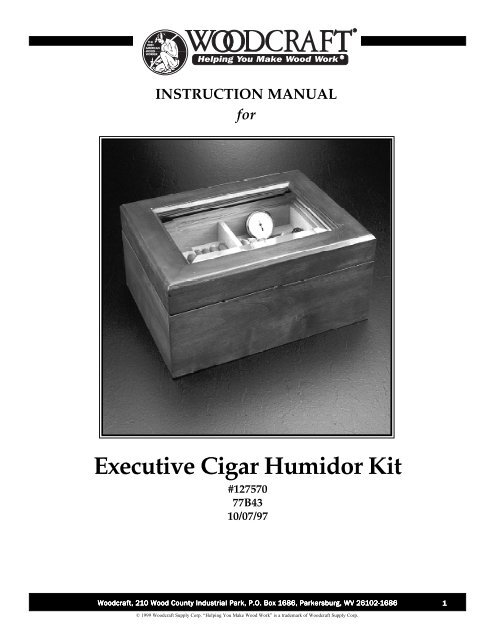

INSTRUCTION MANUAL<br />

for<br />

<strong>Executive</strong> <strong>Cigar</strong> <strong>Humidor</strong> <strong>Kit</strong><br />

#127570<br />

77B43<br />

10/07/97<br />

<strong>Woodcraft</strong>, 210 Wood County Industrial Park, P.O. Box 1686, Parkersburg, WV 26102-1686<br />

© 1999 <strong>Woodcraft</strong> Supply Corp. “Helping You Make Wood Work” is a trademark of <strong>Woodcraft</strong> Supply Corp.<br />

1

Before You Begin<br />

Before beginning the assembly of your <strong>Woodcraft</strong> precut kit, read these instructions and become familiar with the parts list, drawings and<br />

photos which illustrate the text. We also recommend a dry assembly “practice run” on all parts prior to actual gluing. Instructions or<br />

information in bold print are critical for proper assembly and for avoiding irreversible assembly mistakes.<br />

About <strong>Humidor</strong>s<br />

The lining of our <strong>Humidor</strong> <strong>Kit</strong> is Spanish Cedar. This unique wood has a very low sap content and a faint spicy aroma (very unlike domestic<br />

aromatic, white, or red cedar). The lining should be sanded but not finished. The outside of the humidor can be finished with your favorite<br />

oil, urethane or varnish sealer.<br />

When you close your humidor it should create an airtight seal. The unique overlapping wedge joint of the liner in this kit will give you good<br />

results. An airtight seal allows you to control the humidity inside the humidor and keep the tobacco from drying out. A relative humidity of<br />

60% to 80% should be maintained inside your humidor. You can create these humid conditions with the supplied humistat and monitor its<br />

performance with the hygrometer.<br />

After you have installed the humistat it will take about four weeks for the humidity to stabilize inside the box. The wood liner will be absorbing<br />

much of the initial moisture you put into the humidor. Be patient.<br />

Important Notes About Solid Wood<br />

One of the unique characteristics of solid hardwood is the varying hues and patterns within a single piece of lumber. Since no two trees are<br />

identical, no two pieces of wood can be exactly alike either. Each has its own characteristics created by nature, not by man. Unlike plastics<br />

and some veneers in which the grain pattern is symmetrical, solid hardwood has irregular and asymmetrical graining, which adds to the<br />

overall beauty. In the same manner, the various shadings and colors within solid hardwood are part of its beauty.<br />

Clamping<br />

Clamping is necessary to insure a tight accurate fit of glued joints. Conventional pipe or bar clamps can be used as well as band clamps.<br />

When dry fitting make sure you have sufficient clamps for equal pressure over all the joints before actually applying glue to the parts.<br />

Glue<br />

We recommend Titebond II, water resistant, yellow aliphatic resin glue used according to the manufacturer’s instructions because the<br />

<strong>Humidor</strong> is exposed to moisture by way of the internal humidifier. Use a glue brush or cotton swab to spread the glue. A thin even spread on<br />

both parts is best. Clean up excess glue by scraping it off with a knife blade or scraper. Do not wipe glue off with a damp cloth as the<br />

moisture of the cloth will thin the glue and allow it to soak deeply into the wood. This will show in the final finish of your project.<br />

Definitions<br />

Rabbet<br />

Tools Needed<br />

•square •pipe/bar/band clamps • yellow, water-resistant, woodworking glue<br />

•small screw driver •Phillips screwdriver •scratch awl<br />

•chisel •X-Acto knife •mallet<br />

•scrap wood block •CA Glue •glue brushes<br />

2 <strong>Woodcraft</strong>, 210 Wood County Industrial Park, P.O. Box 1686, Parkersburg, WV 26102-1686<br />

© 1999 <strong>Woodcraft</strong> Supply Corp. “Helping You Make Wood Work” is a trademark of <strong>Woodcraft</strong> Supply Corp.

11<br />

24<br />

20 21<br />

12<br />

23<br />

22<br />

1<br />

2<br />

13<br />

4<br />

3<br />

25<br />

10<br />

9<br />

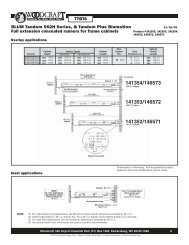

<strong>Cigar</strong> <strong>Humidor</strong> Parts List<br />

14<br />

5 6<br />

15 16 17<br />

19<br />

7 8<br />

18<br />

Part Qty.<br />

Description<br />

Material Dimension T" x W" x L"<br />

1 ......... 1 .................... Base Side, Right, w/pre-cut mortise.................................................. Alder ................................................. 5 /8" x 4 3 /4" x 10 1 /4"<br />

2 ......... 1 .................... Base Side, Left .................................................................................... Alder ................................................. 5 /8" x 4 3 /4" x 10 1 /4"<br />

3 ......... 1 .................... Base Front ........................................................................................... Alder ..................................................... 5 /8" x 4 3 /4" x 14"<br />

4 ......... 1 .................... Base Back, w/pre-bored holes ........................................................... Alder ..................................................... 5 /8" x 4 3 /4" x 14"<br />

5 ......... 1 .................... Top Side, Right, w/pre-drilled hole .................................................... Alder ................................................. 5 /8" x 1 1 /4" x 10 1 /4"<br />

6 ......... 1 .................... Top Side, Left ....................................................................................... Alder ................................................. 5 /8" x 1 1 /4" x 10 1 /4"<br />

7 ......... 1 .................... Top Front .............................................................................................. Alder ..................................................... 5 /8" x 1 1 /4" x 14"<br />

8 ......... 1 .................... Top Back, w/pre-bored holes ............................................................. Alder ..................................................... 5 /8" x 1 1 /4" x 14"<br />

9 ......... 1 .................... Mitered Frame Top-Pre Assembled ................................................... Alder ................................................... 3 /4" x 10 5 /8" x 14"<br />

10....... 1 .................... Bottom .......................................................................................... Spanish Cedar ....................................... 1 /4" x 13 5 /8" x 10 1 /4"<br />

11 ....... 2 .................... Liner, Bottom Sides..................................................................... Spanish Cedar ........................................ 1 /4" x 4 3 /4" x 8 15 /16"<br />

12 ....... 2 .................... Liner, Bottom Front/Back ........................................................... Spanish Cedar ..................................... 1 /4" x 4 3 /4" x 12 13 /16"<br />

13 ....... 2 .................... Tray Supports .............................................................................. Spanish Cedar ............................................... 1 /4" x 2" x 8 3 /4"<br />

14 ....... 1 .................... Slotted Tray Bottom, Base Side ................................................. Spanish Cedar ......................................... 3 /8" x 8 1 /2" x 11 3 /4"<br />

15 ....... 2 .................... Tray Sides .................................................................................... Spanish Cedar ............................................ 3 /8" x 2" x 8-1/2"<br />

16 ....... 2 .................... Tray Front/Back ........................................................................... Spanish Cedar ............................................. 3 /8" x 2" x 12 1 /8"<br />

17 ....... 2 .................... Liner Top Sides ............................................................................ Spanish Cedar .................................... 1 /4" x 11 3 /16" x 8 15 /16"<br />

18 ....... 2 .................... Liner Top Front/Back .................................................................. Spanish Cedar ................................... 1 /4" x 1 13 /16" x 12 13 /16"<br />

19 ....... 1 .................... Center Divider .............................................................................. Spanish Cedar ........................................... 3 /8" x 1 5 /8" x 8 1 /8"<br />

Hardware<br />

20 ...... 1 .................... 55mm Surface Mount <strong>Humidor</strong> Hygrometer (127571)<br />

21 ....... 2 .................... <strong>Cigar</strong> Keepers - Slim with Mounting Clip and Screw (127457)<br />

22....... 2 .................... 10 MM Cylinder Hinges (27C11)<br />

23....... 1 .................... Mortised Box Lid Support (16B34)<br />

24 ...... 3’ ................... Grooved Type Keeper Strip Clear<br />

25 ...... 1 .................... Bevelled Glass<br />

<strong>Woodcraft</strong>, 210 Wood County Industrial Park, P.O. Box 1686, Parkersburg, WV 26102-1686<br />

© 1999 <strong>Woodcraft</strong> Supply Corp. “Helping You Make Wood Work” is a trademark of <strong>Woodcraft</strong> Supply Corp.<br />

3

Surface Preparation<br />

<strong>Humidor</strong> parts are factory sanded, but final finish sanding may be<br />

required according to personal preferences. If additional sanding is<br />

required, sand all parts prior to assembly.<br />

Sanding should be accomplished in a series of steps. Begin with a<br />

180 medium grit paper and remove any scratches or blemishes.<br />

Final sanding should be accomplished with a 320 or 400 grit paper,<br />

removing the scratches left by previous coarser paper. Always sand<br />

with the grain of the wood. When you have finished sanding all<br />

parts, clean them of all dust by vacuuming or using a tack cloth.<br />

Take care not to deform crisp edges or profile lines if additional<br />

sanding is performed on this kit.<br />

Case Assembly Instructions<br />

1. Assemble the humidor on a flat level surface. In a dry run, place<br />

the base sides (#1 and #2), front (#3) and back (#4) on edge, rabbet<br />

side down, and fit the machined joints together. Clamp this assembly<br />

together applying a medium amount of pressure, making sure<br />

that the end joints are fully seated and the edges are flush (Photo<br />

1). When clamping be sure to put scrap blocks of wood between<br />

your clamp heads and the finished surface of the box, this will allow<br />

you to avoid marring the surface with the clamps. Check that the box<br />

is square by placing a try square in an inside corner of the box<br />

(Photo 2). When comfortable with the dry run procedure, glue the<br />

box base together in the order described below.<br />

2. Spread a thin layer of glue on the machined joints of all pieces.<br />

Clamp pieces together with a medium amount of pressure. Check<br />

for square with your try square. If the base is not square, loosen<br />

clamps and re-adjust. Set aside to dry. It is critical that the base of<br />

the box is square.<br />

3. Repeat step 1 of the base dry assembly process using the top<br />

sides (#5 and #6), front (#7) and back (#8) (Photo 3). Clamp. Check<br />

for square. Proceed to next step.<br />

4. Spread a thin layer of glue on the machined joints of all pieces.<br />

Clamp pieces together with a medium amount of pressure. Check<br />

for square with your try square. If the top is not square, loosen<br />

clamps and re-adjust. Set aside to dry. It is critical that the top of the<br />

box is square.<br />

5. After the top assembly has dried, remove clamps and place on a<br />

flat level surface. Apply a thin film of glue on the top edges of the<br />

assembly (edges without hinge holes). Place the pre-assembled<br />

miter frame top (#9), with the routed profile up, on the assembly and<br />

position it so that all of the edges are flush. Apply clamps with a<br />

medium amount of pressure and let dry (Photo 4).<br />

1<br />

2<br />

3<br />

4<br />

4 <strong>Woodcraft</strong>, 210 Wood County Industrial Park, P.O. Box 1686, Parkersburg, WV 26102-1686<br />

© 1999 <strong>Woodcraft</strong> Supply Corp. “Helping You Make Wood Work” is a trademark of <strong>Woodcraft</strong> Supply Corp.

6. Dry fit the bottom (#10) in the rabbetted edges of the base<br />

“frame”. It’s all right if the bottom is slightly loose in the rabbet.<br />

Remove box bottom and place a thin film of glue on the inside of the<br />

rabbet. Place the box bottom in the rabbet edge and clamp with a<br />

medium amount of pressure (Photo 5). It is not critical that the<br />

bottom be square in the recess.<br />

Finishing<br />

Only the exterior of the box and the inside surface where the box top<br />

and bottom meet needs to be finished. The Spanish Cedar lining will<br />

cover the remaining interior of the box. Lightly sand the exterior of<br />

the box in preparation for finishing. Use a sanding block and be<br />

careful not to round off corners.<br />

1. Remove any dust, which may have accumulated during the<br />

building process and final sanding by vacuuming or using a tack rag.<br />

2. The wood may be stained or left natural. It should be sealed with<br />

a topcoat such as varnish, lacquer, polyurethane, or oil finish. If this<br />

is one of your first finishing projects and you are unsure how to<br />

proceed to get the effect you want, we suggest you obtain a copy of<br />

a good general book on wood finishing. Do not rush the finishing of<br />

your kit. Take your time, be very careful, experiment on scrap wood,<br />

and you will be rewarded with a truly handsome project.<br />

Assembling the <strong>Cigar</strong> Trays, <strong>Cigar</strong> Tray<br />

Supports and Liner<br />

1. Place a thin film of glue on the rabbetted surfaces of the tray<br />

front and back (#16) and the tray sides (#15) and position them on<br />

the slotted tray bottom (#14). Apply clamps, apply a medium amount<br />

of pressure and let dry. Spot glue the center divider (#19) in the<br />

center of the cigar tray (Photo 6).<br />

2. After the box is finished and thoroughly dried, you can insert the<br />

Spanish Cedar lining (parts # 11-12, 17-18). Dry fit the pieces in the<br />

top and base of the box (Photo 7). Do not force the liner pieces into<br />

place. If the pieces fit too tightly, lightly sand the ends until they fit<br />

snugly in place.<br />

3. Once satisfied with the dry fit, remove the pieces and place a<br />

small drop or two of yellow glue on the backs of each piece and<br />

return them to their position in the box top and bottom. By spot<br />

gluing the cedar in the box, you will be able to replace the cedar<br />

lining as it ages and looses its aroma.<br />

4. Spot glue the cigar tray supports (#13) on the interior sides of the<br />

base (photo #8).<br />

5<br />

6<br />

7<br />

8<br />

<strong>Woodcraft</strong>, 210 Wood County Industrial Park, P.O. Box 1686, Parkersburg, WV 26102-1686<br />

© 1999 <strong>Woodcraft</strong> Supply Corp. “Helping You Make Wood Work” is a trademark of <strong>Woodcraft</strong> Supply Corp.<br />

5

Installing the Beveled Glass<br />

1. Because the glass keeper strip (#23) is flexible we found that<br />

inserting the strip in the frame and then cutting the strip to fit, as it<br />

is installed, is more accurate than measuring the interior of the<br />

frame and cutting pieces prior to insertion. Carefully place the<br />

beveled glass into the rabbetted frame. Start by cutting a 45° cut on<br />

one end of the keeper strip (Photo #9). With the glass in the<br />

rabbetted frame, insert the serrated edge of the keeper strip into<br />

the slot. Gently push the keeper strip in until it seats flush. Mark the<br />

proper length of the strip, remove from the groove and cut 45° at<br />

your mark. Continue this process around the frame. Using the<br />

flexible keeper strip makes it easy to remove the beveled glass for<br />

cleaning.<br />

Mounting the Hardware<br />

1. Place the two 10mm hinges (#21) in the holes at the back of the<br />

box taking care to position the leaves of the hinges perpendicular to<br />

the back of the box and the top of the barrels flush with the wood<br />

surface. This will ensure that the hinges open and close easily and<br />

do not bind (Photo #10). Using a very small screwdriver, tighten the<br />

screws of the hinges. By tightening the screws you will be expanding<br />

the barrel slightly so the hinge will be secured within the hole. No<br />

glue is needed to keep the hinges in place.<br />

2. Place the lid support (#22) into the mortise on the right side of<br />

the box base (Photo #11). Use a scratch awl to make starter holes<br />

through the support and into the side of the box. Secure in place<br />

with the provided mounting screws. Put a small drop of CA glue on<br />

and around the cylindrical stem of the stay and place it into the<br />

mating hole in the top of the lid. Let dry.<br />

3. Place the hygrometer (#19) in the cigar tray in a convenient<br />

location so that you can read the dial through the beveled glass<br />

when the humidor is closed.<br />

4. Fill the Slim <strong>Cigar</strong> Keeper humidifiers (#20) according to the<br />

manufacture’s instructions. Place one in the base of the humidor<br />

and the other in the cigar tray.<br />

9<br />

10<br />

11<br />

6 <strong>Woodcraft</strong>, 210 Wood County Industrial Park, P.O. Box 1686, Parkersburg, WV 26102-1686<br />

© 1999 <strong>Woodcraft</strong> Supply Corp. “Helping You Make Wood Work” is a trademark of <strong>Woodcraft</strong> Supply Corp.