Download the PDF - Global Solar Technology

Download the PDF - Global Solar Technology

Download the PDF - Global Solar Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Why backsheet standards are anything but standard<br />

Why backsheet standards are<br />

anything but standard<br />

The need to clarify testing procedures and ensure<br />

product performance<br />

Michelle Ostiguy, Director, Photovoltaic & Barrier, Flexcon, Spencer, Massachusetts, USA<br />

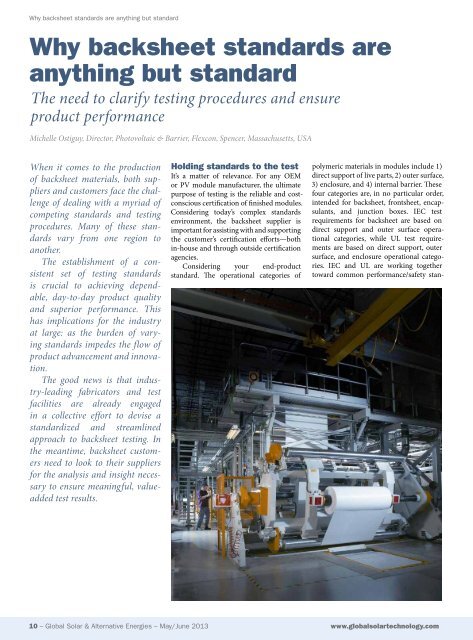

When it comes to <strong>the</strong> production<br />

of backsheet materials, both suppliers<br />

and customers face <strong>the</strong> challenge<br />

of dealing with a myriad of<br />

competing standards and testing<br />

procedures. Many of <strong>the</strong>se standards<br />

vary from one region to<br />

ano<strong>the</strong>r.<br />

The establishment of a consistent<br />

set of testing standards<br />

is crucial to achieving dependable,<br />

day-to-day product quality<br />

and superior performance. This<br />

has implications for <strong>the</strong> industry<br />

at large: as <strong>the</strong> burden of varying<br />

standards impedes <strong>the</strong> flow of<br />

product advancement and innovation.<br />

The good news is that industry-leading<br />

fabricators and test<br />

facilities are already engaged<br />

in a collective effort to devise a<br />

standardized and streamlined<br />

approach to backsheet testing. In<br />

<strong>the</strong> meantime, backsheet customers<br />

need to look to <strong>the</strong>ir suppliers<br />

for <strong>the</strong> analysis and insight necessary<br />

to ensure meaningful, valueadded<br />

test results.<br />

Holding standards to <strong>the</strong> test<br />

It’s a matter of relevance. For any OEM<br />

or PV module manufacturer, <strong>the</strong> ultimate<br />

purpose of testing is <strong>the</strong> reliable and costconscious<br />

certification of finished modules.<br />

Considering today’s complex standards<br />

environment, <strong>the</strong> backsheet supplier is<br />

important for assisting with and supporting<br />

<strong>the</strong> customer’s certification efforts—both<br />

in-house and through outside certification<br />

agencies.<br />

Considering your end-product<br />

standard. The operational categories of<br />

polymeric materials in modules include 1)<br />

direct support of live parts, 2) outer surface,<br />

3) enclosure, and 4) internal barrier. These<br />

four categories are, in no particular order,<br />

intended for backsheet, frontsheet, encapsulants,<br />

and junction boxes. IEC test<br />

requirements for backsheet are based on<br />

direct support and outer surface operational<br />

categories, while UL test requirements<br />

are based on direct support, outer<br />

surface, and enclosure operational categories.<br />

IEC and UL are working toge<strong>the</strong>r<br />

toward common performance/safety stan-<br />

10 – <strong>Global</strong> <strong>Solar</strong> & Alternative Energies – May/June 2013 www.globalsolartechnology.com