download the PDF - Global Solar Technology

download the PDF - Global Solar Technology

download the PDF - Global Solar Technology

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

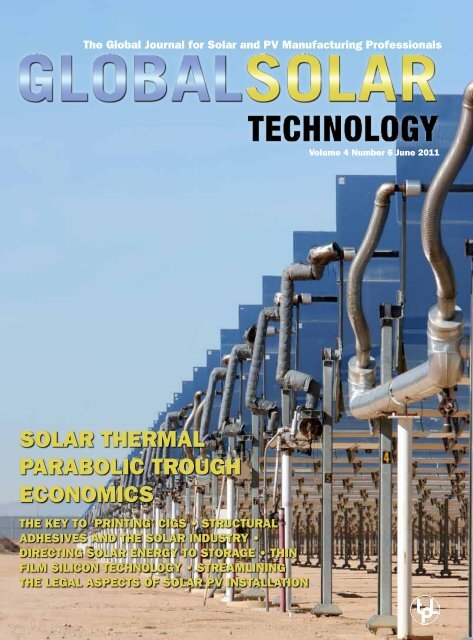

The <strong>Global</strong> Journal for <strong>Solar</strong> and PV Manufacturing ProfessionalsVolume 4 Number 6 June 2011<strong>Solar</strong> <strong>the</strong>rmalparabolic trougheconomicsThe key to ‘printing’ CIGS • Structuraladhesives and <strong>the</strong> solar industry •Directing solar energy to storage • Thinfilm silicon technology • Streamlining<strong>the</strong> legal aspects of solar PV installation

Contents<strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong>is distributed by controlledcirculation to qualifiedpersonnel. For all o<strong>the</strong>rs,subscriptions are available ata cost of £110/US $220/€165for <strong>the</strong> current volume (6issues).No part of this publicationmay be reproduced, storedin a retrieval system,transmitted in any form orby any means —electronic,mechanical, photocopying,recording or o<strong>the</strong>rwise—without <strong>the</strong> prior writtenconsent of <strong>the</strong> publisher.No responsibility isaccepted for <strong>the</strong> accuracyof information containedin <strong>the</strong> text, illustrations oradvertisements. The opinionsexpressed in <strong>the</strong> articles arenot necessarily those of <strong>the</strong>editors or publisher.ContentsEDITORIAL2 Managing <strong>the</strong> growth of solar powerAlan RaeFEATURES4 Thin film silicon technologyChris O’Brien8 Case Study: The key to ‘printing’ CIGS: tighttolerance control10 Special Report: <strong>Solar</strong> <strong>the</strong>rmal parabolic trougheconomics12 Interview: Structural adhesives and <strong>the</strong> solarindustry: standing <strong>the</strong> test of time16 Market is murky on FiT cuts, natural disastersand renewed economic uncertaintyJon Custer-Topai25 Interivew—Streamlining <strong>the</strong> legal aspectsof solar PV installation811Volume 4, No. 6June 2011© Trafalgar Publications Ltd.26 Show preview: Intersolar EuropeDesigned and Publishedby Trafalgar Publications,Bournemouth, UnitedKingdom32 Directing solar energy to storagePLUS6 Industry news28 Technological developments29 Analyst buzz33 New products38 International diary14Flexible organic solar cellsdeveloped at imec. (p 11)Visit www.globalsolartechnology.com for <strong>the</strong> latest news and more, every day.www.globalsolartechnology.com<strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 – 1

THINFABEconomically Viable<strong>Solar</strong> Power withThin Film Silicon – NOW!Lowest Module Production Costs of 0.50/Wp withModule Efficiency of 10% Stabilized at 143 Wp…and a New Champion Cell with11,9% Stabilized EfficiencyOerlikon <strong>Solar</strong> proudly announces <strong>the</strong> new THINFAB which reduces <strong>the</strong> manufacturing cost of thin film silicon modulesto a record breaking 0.50/Wp, with 10 percent stabilized efficiency and 143 Wp module performance. Beyond that weintroduce our new world record breaking cell efficiency of stabilized 11,9 percent on Micromorph ® technology. Find outmore about our non-toxic, environmentally friendly solar technology at www.oerlikon.com/solar/thinfab.

Thin film silicon technologyThin film silicontechnologyLow cost thin film is wellpositioned for new policiesChris O’BrienThe past two months have seendramatic changes in solar incentivepolicies around <strong>the</strong> world, changesthat are certain to change <strong>the</strong> landscapefor end PV markets in coming years. Forthis article, we will focus on three specificpolicy changes that have occurred within<strong>the</strong> past couple of months:1. Italy. On May 4, 2011, <strong>the</strong> 4thConto was approved, and with it asweeping set of changes to <strong>the</strong> feedin-tariffschedule in <strong>the</strong> world’ssecond-largest PV market. Under<strong>the</strong> revised schedule, feed-in tariffrates are reduced each month in2011, and again on a bi-annualschedule in 2012. For residentialrooftop systems, feed-in-tariff rateswill be reduced by a total of 23%in 2011, and ano<strong>the</strong>r 15% in 2012.For large ground-mounted systems(over 1 MW), feed-in-tariff ratesare reduced 35% in 2011 and anadditional 23% in 2012.2. California. On April 12, 2011,Governor Jerry Brown signedinto law an ambitious newrenewable energy requirementfor California, requiring that 33%of electricity consumed in <strong>the</strong>state be sourced from renewableresources including solar by 2020.Note that California is <strong>the</strong> secondlargestenergy market in <strong>the</strong> U.S,comprising approximately 7% oftotal U.S. electricity consumption(259 TWh). While <strong>the</strong>re is lessprice certainty in <strong>the</strong> competitivePPA market in <strong>the</strong> U.S., Federaltax incentives for solar (30%investment tax credit, acceleratedtax depreciation) are in place for atleast <strong>the</strong> next five years.In <strong>the</strong> short term, it’s going to be a wild ridefor <strong>the</strong> industry.3. China. Ano<strong>the</strong>r major change in<strong>the</strong> solar policy landscape occurredlast month with <strong>the</strong> news thatChina has revised its long termnational strategic goals for solar,now targeting a cumulative 50 GWof solar to be installed in China by2020, significantly higher than <strong>the</strong>previous 2020 target of 20 GW. Like<strong>the</strong> U.S. <strong>the</strong>re is at this point in timeno national feed in tariff programto provide investor certainty onFigure 1. Micromorph® cost reduction.solar PV energy prices; however itis reasonable that for large projects,a competitive LCOE will be in acomparable range to <strong>the</strong> U.S.What do <strong>the</strong>se positive and negativechanges in solar incentive and mandatepolicies mean for PV demand? In <strong>the</strong>short term, it’s going to be a wild ridefor <strong>the</strong> industry, as reduced FIT projectdevelopment and increased productioncapacity create significant excess inventory4 – <strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 www.globalsolartechnology.com

Thin film silicon technologyInstalled System LCoE (€/kWh) IRR (100% Equity)Price (€/W)Italy 500 kW rooftop €2.16/W €0.11/kWh 16.6%California 10 MW €1.71/W €0.08/kWh 8.5%China 10 MW €1.48/W €0.10/kWh 8.5%Table 1. Results of <strong>the</strong> analysis.that is sold at prices that approach <strong>the</strong>marginal cash cost of production. At<strong>the</strong> same time, <strong>the</strong>se reduced prices willcreate an elastic demand increase in largemarkets outside of Europe, demand thatis reinforced by new renewable mandatepolicies in US and China.There will also be winners and losersamong <strong>the</strong> different PV technologiesin <strong>the</strong>se volatile market shifts. In short<strong>the</strong> winners in this scenario will bethose technologies that have <strong>the</strong> lowestsustainable cost of production, and at <strong>the</strong>same time have sufficient track record in<strong>the</strong> market to qualify for low cost projectfinancing. The losers in <strong>the</strong> months andyears ahead will be those producers whohave a less efficient cost structure—due tohigh production costs, inefficient marketchannels or high cost of financing due tobeing less bankable.Thin film silicon is well positioned for<strong>the</strong>se new market conditions. Driven bysemiconductor equipment industry leadersthat are experienced in delivering continualand rapid technology evolution and costdeclines, <strong>the</strong> cost of ownership has beenreduced by over 50% in just <strong>the</strong> past threeyears. Oerlikon <strong>Solar</strong> and o<strong>the</strong>r thin filmsilicon leaders continue to invest heavilyinto product and equipment R&D, andhave identified significant opportunitiesfor fur<strong>the</strong>r future cost reductions andmodule performance improvements.As an illustration of <strong>the</strong> competitivepositioning for thin film silicon in <strong>the</strong> wakeof <strong>the</strong> above-described policy changes,we have presented below three differentscenarios, in three different regions:1. 500 kW rooftop application in Italy,operational in H2 20122. 10 MW ground mountedapplication in California, installedin H2 2012, competing for RPS3. 10 MW ground mountedapplication in China, installed inH2 2012Key assumptions for this analysis• Module price. Based on 2011cost of ownership for Oerlikon<strong>Solar</strong> ThinFab (120 MW capacity,10% average module efficiency),assuming production at a plant in<strong>the</strong> region. Assumes gross marginpercentage of 35%• BOS costs. For 10 MW installations,based on bottoms-up benchmarkcosts from leading EPC’s adjustedfor efficiency differences comparedwith CdTe or c-Si. Assume BOS50% higher for 500 kW rooftop.Estimated 2012 BOS costs asfollows:i. Italy 500 kW rooftop:€1.36/Wii. US 10 MW ground mount:€0.91/Wiii. China 10 MW groundmount: €0.68/W• Energy production. Assume 1690kWh/kW for Italy (Bari), 1639 forCalifornia (San Diego) and 1638for China (Yingchuan). Note that<strong>the</strong>se values are based on <strong>the</strong> use ofMicromorph®, with an energy yieldthat is approximately 5% higherthan typical yield of crystalline PV.• Available incentives. For Italyscenario, assume H2 2012 FITlevel, including 10% premium forin-country production (€0.22/kWh). For US assume 30% ITC and5-year MACRS. For China, assumeno incentives.• LCoE escalator—2.5% p.a. for Italyand US, 4.0% for China.• Financing. Results are based on100% equity.ResultsThe results of <strong>the</strong> analysis, Table 1,demonstrate that TF Si technologywill continue to be among those PVtechnologies that are competitive even aspolicies shift and margins are compressed.The project in Italy shows an excellentoverall rate of return for project investors,even with <strong>the</strong> reduced FIT levels. Theresults for <strong>the</strong> 10 MW projects in US andChina demonstrate that continuing costreductions made possible by technology/equipment suppliers position thin filmsilicon to deliver low-cost power thatis competitive with o<strong>the</strong>r leading PVtechnologies in renewable mandatemarkets.Chris O’Brien is head of marketdevelopment for Oerlikon <strong>Solar</strong>, and is basedin Washington, DC. He has held seniormanagement positions with leading solarPV companies including Sharp <strong>Solar</strong> and BP<strong>Solar</strong> since 1995. Chris has previous careerexperience in <strong>the</strong> energy efficiency andindependent power industries. He holds anengineering degree from Dartmouth Collegeand an MBA from Stanford University.www.globalsolartechnology.com<strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 – 5

Industry The electronic news interconnection hierarchyIndustry newsSanterno chooses Sanmina-SCI aspartner to build solar inverters inOttawa, CanadaSanmina-SCI will manufacture Santerno’ssolar inverters for commercial applicationsat its Ottawa, Ontario, Canada facility.Production of <strong>the</strong> solar inverters atSanmina-SCI’s Ontario facility expandsSanterno’s manufacturing base into NorthAmerica, enabling local logistics servicesto its customers while meeting Ontario’sFeed-In Tariff domestic content requirements.www.sanmina-sci.com, www.santerno.com3S Modultec client KISCO startsmodule production in record timeWith <strong>the</strong> help of 3S Swiss <strong>Solar</strong> Systems,KISCO has completed <strong>the</strong> certificationof its module production in Korea withina period of just a few weeks. Since mid-March, KISCO has been producing highlyefficient, crystalline solar modules on anewly installed 65 MW production linefrom 3S Modultec. Once it was up and running,<strong>the</strong> production process was successfullyinspected by TÜV Rheinland barelysix months after signing <strong>the</strong> contract.KISCO has benefitted from, among o<strong>the</strong>rthings, <strong>the</strong> certification service offered by3S, which has already been successfullyimplemented in a number of projects by3S Modultec in conjunction with TÜVRheinland. www.3s-pv.ch, www.meyerburger.com,www.getwatt.co.krBürkle supplies seven-openingYpsator Lamination Line to Willard& Kelsey <strong>Solar</strong> GroupBürkle North America Inc., and Willard &Kelsey <strong>Solar</strong> Group announced today thatW&K has begun high-volume productionof Cadmium Telluride (CdTe) solar panelsat <strong>the</strong>ir plant in Perrysburg, Ohio usingBürkle’s proven Multi Daylight Laminator,<strong>the</strong> Ypsator. The lamination system is <strong>the</strong>first of its type in <strong>the</strong> North Americanmarket having a host of significant featuresincluding <strong>the</strong>rmal fluid platen heatingassuring uniform heating of <strong>the</strong> modulesacross <strong>the</strong> platen, minimized edge pinchdue to <strong>the</strong> hydraulic hot pressing step,reduced cycle time due to <strong>the</strong> split laminationprocess and uniform cooling resultingin flat modules having reduced internalstress. www.ypsator.com<strong>Solar</strong>3D completes design of lightcollector for solar cell<strong>Solar</strong>3D, Inc. has completed <strong>the</strong> design of<strong>the</strong> Light Collector section, a critical partof its novel solar cell. Inspired by lightmanagement techniques used in fiber opticdevices, <strong>the</strong> company’s innovative solar celltechnology utilizes a 3-dimensional designto trap sunlight inside micro-photovoltaicstructures where photons bounce arounduntil <strong>the</strong>y are converted into electrons.<strong>Solar</strong>3D’s management believes that thisbreakthrough solar cell design will dramaticallychange <strong>the</strong> economics of solarenergy. www.solar3d.comCarl Zeiss Optronics presents solarmirror to research instituteAt <strong>the</strong> end of April, Carl Zeiss Optronicspresented <strong>the</strong> GREGOR M1 solar mirrorto a research consortium. The mirror wasbuilt under <strong>the</strong> full responsibility of <strong>the</strong>German optics company. Following internallapping and polishing, it features deviationfrom <strong>the</strong> nominal surface of only 20nanometers. The 1.5 meter solar mirrorwill be installed at <strong>the</strong> Teide Observatoryin <strong>the</strong> Canary Islands. Carl Zeiss Optronicswas responsible for <strong>the</strong> performance ofall three solar mirrors. With <strong>the</strong> deliveryof <strong>the</strong> M1, <strong>the</strong> Gregor Telescope can nowenter service. It replaces <strong>the</strong> 45 cm GregorCoudé Telescope that has been used for atotal of 40 years for research. www.zeiss.de/optronicsBTU International receives order formultiple solar cell rework furnacesBTU International has received an orderfor multiple hydrogen annealing furnacesfrom a major Asian solar cell manufacturer.BTU has extensive experience with hydrogenannealing processes and equipment.Today, with more than 125 hydrogen furnacesin operation in <strong>the</strong> semiconductor,nuclear and o<strong>the</strong>r industries, <strong>the</strong> safety andreliability of BTU’s hydrogen tools is wellestablished. www.btu.comCentrosolar introduces S-Seriespanels made in OntarioCentrosolar Canada has released <strong>the</strong>S-Series photovoltaic modules, now availableto local solar dealers and installers.Engineered in Germany and manufacturedin Ontario, Centrosolar Canada’s S-Seriesis designed for both residential and commercialapplications. The S-Series moduleis designed to deliver reliable and peakperformance power levels in cloudy and6 – <strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 www.globalsolartechnology.com

The key to ‘printing’ CIGS: tight tolerance controlCase studyThe key to ‘printing’ CIGS:tight tolerance controlChallengeIncrease precision and speed whilereducing development time fordemanding solar-cell production process.Solution• Bosch Rexroth SYNAX 200 shaftlessmotion control system• IndraDrive C Converters• MSK Synchronous Servo MotorsWith <strong>the</strong> Rexroth SYNAX 200 system, all <strong>the</strong> machines’ axes are electronically synchronized sowhen <strong>the</strong> line speed increases or decreases, <strong>the</strong> axes ramp up or down toge<strong>the</strong>r to maintainprecise web position.One of <strong>the</strong> brightest ideas in renewableenergy is using solar-cellpanels to generate electricity withoutburning hydrocarbon fuels. But comparedto generating electricity from coal,<strong>the</strong> cost of producing electricity with solarcells is high. In recent years, one solar cellpanel manufacturer has been able to reduce<strong>the</strong> cost of solar cell panels dramatically,thanks to innovative machinery developedby Northfield Automation Systems, usinga Bosch Rexroth shaftless motion controlsystem.“Manufacturing typical siliconwafersolar cells is expensive,” explainsDarin Stotz, sales manager for NorthfieldAutomation Systems. “That’s because aphotovoltaic solar cell is built in layers, and<strong>the</strong> silicon semiconductor layer that turnslight into electric current must be appliedin a complex process known as vacuumdeposition,”The solar cell panel manufacturerdeveloped a new deposition method usingtechnology from Northfield AutomationSystems, which specializes in roll-to-rollthin material handling in <strong>the</strong> flexible circuitindustry. They brought <strong>the</strong> expertise<strong>the</strong> solar-cell manufacturer criticallyneeded to optimize <strong>the</strong>ir processes.“We implemented a Rexroth motioncontrol solution on machinery that appliessemiconductor material in an open-airenvironment, instead of inside vacuumchambers,” says Stotz.“Basically, this manufacturer appliescopper indium gallium (di)selenide (CIGS)onto a web of thin foil in a process thatresembles offset printing. Consequently,<strong>the</strong>y can produce CIGS solar cells that aremuch less expensive than silicon wafercells, because it eliminates <strong>the</strong> complexityBenefits• Precise web control for tightregistration in thousandths ofmillimeters• Provides over one million countsper revolution for precise positionmonitoring• Eliminates mechanical-componentlimitations by using servodrives and electronic cams• Digital control platform enablesElectronic Line Shafting as avirtual drive• Simple programming environmentuses parameter library toeliminate coding and dramaticallyreduce development time• Modular system simplifies shippingand allows for flexibility inline configurationof vacuum deposition.”The process is similar to printing <strong>the</strong>Sunday newspaper’s comics, in whichlayers of ink are aligned on a web of paperso <strong>the</strong> colors do not blur. But this processrequires far tighter registration, as tight asone-thousandths of a millimeter. This levelof precision in web handling presentedNorthfield with several challenges.“This customer feeds rolls of foilthrough rolls in large presses similar tothose used in rotogravure printing,” saysStotz. “Their challenge was to find a driveand motion control system that could syn-8 – <strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 www.globalsolartechnology.com

The key to ‘printing’ CIGS: tight tolerance controlBy applying copper indium gallium (di)selenide onto a web of thin foil in aprocess that resembles offset printing, <strong>the</strong>manufacturer can produce CIGS solar cellsthat are much less expensive than siliconwafer cells.chronize multiple axes of <strong>the</strong> rolls in onelong production line. As <strong>the</strong> web moves>100 feet down <strong>the</strong> line through differentprocesses, <strong>the</strong> axes have to align <strong>the</strong> foilmaterial in proper position for <strong>the</strong> nextstep. From step to step, we need tight tolerancecontrol so what happens in one operationlines up with <strong>the</strong> next. If <strong>the</strong> layersdo not match up, <strong>the</strong>n <strong>the</strong> solar cell mustbe scrapped, resulting in wasted materials.Consequently, <strong>the</strong> machinery has to startwith tight tolerances, <strong>the</strong>n maintain it at<strong>the</strong> next step so we don’t have to make a lotof adjustments to <strong>the</strong> web’s tension, speedand position.”In conventional printing, rotary pressesoften use mechanical shafts and gears,but <strong>the</strong>y do not come close to providing<strong>the</strong> accuracy required in this application.Nei<strong>the</strong>r can stepper motors, a solution thatNorthfield Automation Systems has traditionallyemployed in <strong>the</strong>ir web-handlingmachinery.Motion Tech Automation, a local distributorof Bosch Rexroth motion controlproducts, assisted Northfield in finding asuperior alternative—<strong>the</strong> Rexroth SYNAX200 shaftless drive system. With <strong>the</strong>SYNAX 200 system, all <strong>the</strong> machines’ axesare electronically synchronized so when<strong>the</strong> line speed increases or decreases, <strong>the</strong>axes ramp up or down toge<strong>the</strong>r to maintainprecise web position.To maintain accuracy in thousandthsThe modularity inherent in <strong>the</strong> SYNAX 200 system made it possible to develop modular machinedesigns, which simplifies shipping and provides flexibility in configuring <strong>the</strong> line to meetvarious requirements of <strong>the</strong> solar-cell production process.of millimeters along a 100-foot line,Northfield specified Bosch Rexroth’sSYNAX 200 control platform along withIndraDrive intelligent servo drives usingSERCOS III industrial E<strong>the</strong>rnet communication.Designed for <strong>the</strong> web-handling industry,Rexroth’s SYNAX 200 is a control anddrive solution that provides tight control ofweb positions by making minute changesin speed to maintain registration of <strong>the</strong>layers. Instead of mechanical cam shaftsand gears, tightly synchronized digitalservo drives and dynamic servo motorsrun off a standardized control platform tocreate virtual drives, an approach knownas Electronic Line Shafting. The primaryshaft is a virtual master axis. A programmableelectronic gearbox ratio simulates<strong>the</strong> mechanical gearbox between <strong>the</strong>master axis and <strong>the</strong> drive. The master axismaintains a fixed relationship between itsposition and o<strong>the</strong>r virtual slave axes toachieve positioning accuracy that cannotbe obtained with mechanical gearboxes—or even stepper motors.Web handling can be done with steppermotors, however <strong>the</strong> positioning accuracyof stepper motors is between 500 and50,000 steps per revolution. That may seemhigh, but a servomotor using sine/cosineencoders for position monitoring providesover one million counts per revolution.That improves resolution and accuracy byseveral orders of magnitude.The customer was not previouslyfamiliar with Electronic Line Shafting.According to Stotz, “They knew what servomotorswere capable of, but we showed<strong>the</strong>m how one single controller could runall those axes and how <strong>the</strong> architecturecould achieve <strong>the</strong> precision <strong>the</strong>y wanted.”For this application, <strong>the</strong> SYNAX platformincluded a machine vision camerathat focuses on registration marks on<strong>the</strong> web. Position inputs are translated bya PLC that sends instructions to a rackmounted PPC multiaxis controller. Thecontroller communicates with <strong>the</strong> RexrothIndradrive C Converters powering RexrothMSK synchronous servo motors, whichmake <strong>the</strong> appropriate position and speedadjustments as required. Each drive functionsas a stand-alone device with its ownpower supply. Data is transmitted between<strong>the</strong> motion controller and drives in realtime over SERCOS III industrial E<strong>the</strong>rnetthat provides noise immunity.The servomotors adjust speed to varyweb tension—and use speed to vary printlocation. Speed and tension can be adjustedby 1 percent increments as needed.With <strong>the</strong> SYNAX 200, achieving preContinued on page 11www.globalsolartechnology.com<strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 – 9

<strong>Solar</strong> <strong>the</strong>rmal parabolic trough economicsSpecial report<strong>Solar</strong> <strong>the</strong>rmal parabolictrough economicsAlthough <strong>Global</strong> <strong>Solar</strong><strong>Technology</strong> is usuallyfocused on solar PV, weare constantly looking forinformation that our readerswill find useful on related technologyand infrastructure issues. CSP Today hasjust published a comprehensive reportentitled “CSP Parabolic Trough Report—Costs and Performance” (www.csptoday.com/costs). Given <strong>the</strong> increasing interest inthis technology in <strong>the</strong> USA as well as <strong>the</strong>Middle East and North Africa, we thoughtwe’d take a look at this fascinating and wellresearched report.The authors interviewed more than 45senior executives at companies involvedin CSP, including developers, componentmanufacturers, EPCs and research labs. Theteam also collected data on costs from <strong>the</strong>interviewees and input information suchwater costs, insurance and labor necessaryto calculate costs of CSP. The collated datawas <strong>the</strong>n run through a model called <strong>the</strong><strong>Solar</strong> Advisory Model (SAM), developedby NREL, and <strong>the</strong> final results and reportanalysis were peer reviewed by leading scientistsat CIEMAT, developers (Abengoa)and industry associations (Protermosolar).Where are parabolic troughsbeing installed?There are 26 plants in total with 12 in <strong>the</strong>USA and 11 in Spain. Spain leads in capacitywith 1200 MW plus 600 under construction,followed by <strong>the</strong> USA with 800MW and 1200 under construction—but<strong>the</strong> planned future capacity in <strong>the</strong> USAstands at an impressive 10.9 GW, largerthan <strong>the</strong> next 10 nations combined.Why are <strong>the</strong>y being installed?The levelized cost of energy (LCOE) is significantlylower than that of conventionalsolar PV: 0.15-0.24 €/kWh vs. 0.25-0.325 €/kwh for solar PV. Also, <strong>the</strong>rmal energy canbe conveniently stored to help to balancesupply and demand.12000 10000 8000 6000 4000 2000 0 Portugal 13 50 67 100 100 100 130 200 200 215 215.1 275 France Iran Egypt Jordan Planned CSP capacity per country (in MW).What is LCOE and how was itcalculated?The LCOE was calculated according to <strong>the</strong>simplified IEA method (Ref. InternationalEnergy Agency (IEA), Guidelines for <strong>the</strong>economic analysis of renewable energytechnology applications, (1991)) using euroas <strong>the</strong> currency. Equation 1 shows how <strong>the</strong>LCOE was calculated.How do <strong>the</strong>se costs workout relative to o<strong>the</strong>r energysources? And what is <strong>the</strong>optimum plant size?A major challenge to CSP plants is <strong>the</strong>irinherently high capita cost. However, conventionalpower plants suffer from highfossil- fuel-dependent running costs, andthus <strong>the</strong> running costs of parabolic troughplants were found to be very competitive.The optimum plant size derived from <strong>the</strong>model used in this report was found to bearound 150 MW.UAE India South Africa Tunisia Algeria China Equation 1:LCOE =Morocco Cost LifeCycle440 Israel 817 Australia 1338 Spain 10910.8 How do parabolic troughswork?The electricity is generated using by transferring<strong>the</strong> heat generated from solar collectionto a heat transfer fluid and <strong>the</strong>n toa steam heat exchanger, and <strong>the</strong>n convertingit into electricity using a conventionalUSA Energy LifeCycle= f cr!C Invest+ C O&M+ C FuelEC NetWhere f cris <strong>the</strong> annuity factor calculatedas per Equation 2:f cr= k d !(1+ k d )n(1+ k d) n "1 + k Insurance Where k dis <strong>the</strong> real debt interest rate,k insuranceis <strong>the</strong> annual insurance rate, n is<strong>the</strong> depreciation period in years, C investis<strong>the</strong> total investment of <strong>the</strong> plant, C O&Mis<strong>the</strong> annual O&M cost, C fuelis <strong>the</strong> annualfuel cost and EC netis <strong>the</strong> annual netelectricity.10 – <strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 www.globalsolartechnology.comwww.globalsmt.net

<strong>Solar</strong> <strong>the</strong>rmal parabolic trough economicsPerformance Factors* CSP PTC Wind PV Biomass Natural GasEnergy Resource (GWh/km2/annum) 75-100 25-60 50-60

Structural adhesives and <strong>the</strong> solar industry: standing <strong>the</strong> test of timeInterviewStructural adhesivesand <strong>the</strong> solar industry:standing <strong>the</strong> test of timeAs a major producer of general-purpose and specialty adhesives, LORDCorporation has been at <strong>the</strong> forefront of many industry trends. This isespecially true for <strong>the</strong> solar power industry, which was just coming intoplay when LORD became involved with supplying adhesives for <strong>the</strong> firstsolar-electric generating plant (<strong>Solar</strong> One) in California in <strong>the</strong> early 80s.Not only was <strong>the</strong> solar power installation innovative for its time, so were<strong>the</strong> adhesives used to assemble <strong>the</strong> solar generating equipment. Since<strong>the</strong>n, LORD has pioneered adhesive technology advancements and isnow one <strong>the</strong> foremost suppliers of adhesive solutions to <strong>the</strong> solar powermarketplace.In this interview, Dennis Howard, a retired syn<strong>the</strong>tic polymer chemist,discusses <strong>the</strong> development of polymeric adhesives at LORD and <strong>the</strong>iruse in <strong>the</strong> burgeoning solar industry in <strong>the</strong> 1980s. Dave Pugne, managerof Structural Adhesives <strong>Technology</strong> at LORD, brings us up-to-dateon <strong>the</strong> advances LORD has made in adhesive technology for <strong>the</strong> solarpower industry.Dennis HowardWhat developments in materials weretaking place 30 years ago that warrantedsimilar innovations in adhesives?Dennis Howard: Back <strong>the</strong>n, more andmore manufactured assemblies were usingnew plastic materials that were emerging at<strong>the</strong> time. Many of <strong>the</strong>se assemblies required<strong>the</strong> bonding of plastics to metals, and wewere working on developing adhesives thatcould bond dissimilar materials, besidesadhering metals-to-metals and plastics-toplastics.The adhesive had to be so versatilethat it could bond a metallic material to aplastic material.Describe <strong>the</strong> development of <strong>the</strong>se newpolymeric adhesives at LORD.Howard: At <strong>the</strong> time, <strong>the</strong>se adhesives werevery innovative. We were at <strong>the</strong> forefrontof new polymer development. In our R&Dlabs, we were not just buying stock componentsand mixing <strong>the</strong>m toge<strong>the</strong>r; we wereinvolved in creating new polymeric materialsto formulate <strong>the</strong>se adhesives. It is moredifficult to develop an adhesive that sticksto plastic on one surface and metal onano<strong>the</strong>r surface—but our line of Versilok®adhesives was able to do that—while alsobonding metal-to-metal and plastic-toplastic.The solar industry was also just beginningto develop at that time. What was <strong>the</strong> solarindustry looking for in an adhesive?Howard: <strong>Solar</strong> panels are often made ofdissimilar materials—metal componentsand plastic components. <strong>Solar</strong> assembliesneed to withstand harsh environmentalconditions (rain, wind, sand) and excessivetemperature ranges (panels get coldat night, extremely hot during <strong>the</strong> day, andcold again at night). The solar industry waslooking for an adhesive that could meet<strong>the</strong>se criteria—and Versilok adhesivesseemed to be a natural application for <strong>the</strong>solar market.So, at LORD, you were developing adhesivesthat were a perfect fit for <strong>the</strong> solarindustry.Dave PugneHoward: Yes, we were creating new polymermaterials that could be used in formulatingadhesives that were also very stableagainst degradation due to water and moisture.This new class of polymeric materialsremained flexible at low temperatures butdid not decompose at high temperaturesand <strong>the</strong>refore, would be useful over a verywide temperature range. In developingVersilok adhesives, proprietary componentsenabled <strong>the</strong> formulation to provideextremely good adhesion to metal andplastic.12 – <strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 www.globalsolartechnology.com

Structural adhesives and <strong>the</strong> solar industry: standing <strong>the</strong> test of timecomponents and are easy to apply at <strong>the</strong>job site. Not only could you use Versilok tofabricate <strong>the</strong> sub-assembly, but you couldtake that same adhesive and do <strong>the</strong> finalassembly in <strong>the</strong> field.How did adhesives keep weight down andlower production costs in solar manufacturing?Howard: Adhesives are an ideal substitutefor mechanical fasteners or welding. With<strong>the</strong>se o<strong>the</strong>r production methods, you stillneed a sealant or gasket to seal joints andprevent contaminants, such as dirt, sandand oils, from entering <strong>the</strong> solar assembly.Adhesives “took off <strong>the</strong> table” <strong>the</strong> requirementfor any type of sealant or gasketbecause <strong>the</strong> adhesive became its own sealantor gasket.LORD Versilok 204 and 506 structural adhesives were used to fabricate portions of <strong>Solar</strong>One, <strong>the</strong> first solar-electric generating plant in <strong>the</strong> United States.How have structural adhesives evolvedsince <strong>the</strong> 80s?Dave Pugne: Most of <strong>the</strong> racking systemsused in today’s solar installations are madeof aluminum and are ei<strong>the</strong>r bonded ormechanically fastened to o<strong>the</strong>r substratesto build an assembly. The solar industry islooking for methods to help <strong>the</strong>m decreasemaintenance costs, while improving durabilityand increasing product life expectancy.A new generation of acrylic adhesives,Maxlok adhesives, replaces welding,brazing, riveting and o<strong>the</strong>r mechanicalfastening methods and can be used in awide range of temperature environmentssubject to high impact or high peel loads.They are designed to bond a wide varietyof unprepared metals and dissimilar substrates,with minimal preparation.Did <strong>the</strong> Versilok adhesives gain wideacceptance in <strong>the</strong> solar industry?Howard: The adhesives became very popularin <strong>the</strong> solar industry, especially becauseof <strong>the</strong>ir versatility. They could be used in<strong>the</strong> manufacture of solar equipment andin <strong>the</strong> field to assemble <strong>the</strong> equipment forinstallation. Because many of <strong>the</strong> solarassemblies are large and flat, portions of<strong>the</strong>m are fabricated in <strong>the</strong> shop, but <strong>the</strong>actual installation required some assemblyof <strong>the</strong> various components in <strong>the</strong> field.The adhesives are very easy to use in <strong>the</strong>manufacturing environment to producePugne: Bonding solar panels to <strong>the</strong> rackingsystem eliminates <strong>the</strong> need for numerousfasteners. Adhesives also reduce stresspoints by evenly distributing weight across<strong>the</strong> entire frame. For example, <strong>the</strong> bolts in<strong>the</strong> panels will eventually, over time, beginto work <strong>the</strong>mselves loose due to extremeoutdoor conditions such as wind andrain. Adhesives eliminate this problem.You no longer need to have maintenancepersonnel go into <strong>the</strong> field for regularcheck-ups, or to replace or tighten fasteners.Mechanical fasteners are also prone torusting, while <strong>the</strong> adhesives are formulatedto withstand wind, rain, dirt, sand and saltspray. Installation and construction timeis a lot quicker too, compared to laborintensiveoperations such as welding. TheDid <strong>the</strong> new polymeric adhesives findapplications in o<strong>the</strong>r industries?Howard: LORD embarked on developinga new class of adhesives because manufacturerswere not happy with what was currentlyavailable. Versilok adhesives foundacceptance in many industries, including<strong>the</strong> automotive market and personal recreationalvehicles such as watercraft, snowmobilesand jet skis. It <strong>the</strong>n became apparentthat <strong>the</strong>se adhesives would be usefulfor <strong>the</strong> manufacture and installation ofsolar equipment, considering <strong>the</strong>ir abilityto withstand harsh environments.For <strong>the</strong> <strong>Solar</strong> One installation, LORD Versilok adhesives provided a strong bond that was ableto withstand harsh, hot environments.www.globalsolartechnology.com<strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 – 13

Structural adhesives and <strong>the</strong> solar industry: standing <strong>the</strong> test of time“In dismantling <strong>the</strong> heliostat, <strong>the</strong> adhesiveswere found to be intact after almost 30-yearsof installation. “weight of <strong>the</strong> racking system is reducedwhen mechanical fasteners are eliminated.All of <strong>the</strong>se advantages translate into costsavings whe<strong>the</strong>r it’s inventory costs, laborcosts or production costs.Were <strong>the</strong>re o<strong>the</strong>r advantages to usingVersilok adhesives?Howard: One important aspect of Versilokadhesives was that it did not take a lot ofadhesive to form a very strong bond. Onlya very thin layer of adhesive is needed toimpart a watertight seal. The fact that youneed less adhesive to provide a durablebond is a definitely a cost-saving consideration.And <strong>the</strong> watertight seal goes beyondjust “being watertight”—water will notdegrade <strong>the</strong> adhesive ei<strong>the</strong>r. Even to thisday, those polymeric materials have stood<strong>the</strong> test of time and are still useful in creatingnew adhesive products.How is <strong>the</strong> new generation of adhesivesdifferent from earlier formulations?Pugne: The LORD line of metal-bondingadhesives are now formulated to provide<strong>the</strong> end user with higher degrees of impactand peel strength, increased shelf life, lowtack surfaces, and re-mate-ability properties.These new adhesives feature glassbeadtechnology to insure exact bond-linethickness. Tiny glass beads (only 0.01 in. indiameter), imbedded throughout <strong>the</strong> adhesiveformulation, guarantee that optimumbond-line thickness is achieved when twoparts are mated toge<strong>the</strong>r. The glass beadsact like spacers in <strong>the</strong> bond line to keep <strong>the</strong>bond-line thickness from varying.O<strong>the</strong>r areas where <strong>the</strong>se adhesivesexcel are in application and cure times. Theadhesives are easily dispensed, in <strong>the</strong> manufacturingplant or out in <strong>the</strong> field, fromside-by-side cartridges with a mix ratio of4:1. A variety of cure times allows <strong>the</strong> userto choose <strong>the</strong> adhesive that meets <strong>the</strong>irapplications needs. There are formulationsthat cure very quickly in 3 or 6 minutes tothose that are “open” a bit longer, up to 18minutes.What is <strong>the</strong> connection between LORDand Hughson Chemicals, <strong>the</strong> supplier ofadhesives to <strong>the</strong> <strong>Solar</strong> One installation?Howard: LORD Corporation began asLORD Manufacturing back in <strong>the</strong> 1920s.At that time, <strong>the</strong> company made mostlyrubber-to-metal bonded assemblies suchas motor mounts and vibration controlequipment. The company was not happywith <strong>the</strong> adhesives <strong>the</strong>y were getting from<strong>the</strong>ir supplier, and were looking for betterperforming products. LORD embarkedon developing a new class of adhesives,and created a new company, HughsonChemicals, in <strong>the</strong> late 1950s. The newadhesives were sold under <strong>the</strong> HughsonChemicals name until <strong>the</strong> two divisionswere merged in <strong>the</strong> 1990s.How did LORD (Hughson Chemicals)become involved with <strong>the</strong> solar-electricgenerating plant in <strong>the</strong> early 80s?Howard: A major subcontractor for <strong>the</strong><strong>Solar</strong> One installation was awarded a contractto provide 1,800 heliostats for <strong>the</strong>first solar-electric generating plant in <strong>the</strong>United States near Barstow, California.They were looking for ways to make solarpower cost competitive with fossil-fuelplants and to find <strong>the</strong> types of materialsthat would meet <strong>the</strong> demands of solarenergy technology. The company knewthat adhesives would be a cost-effectivesolution, but <strong>the</strong>y needed a formulationthat could withstand <strong>the</strong> ultraviolet effectsfrom <strong>the</strong> sun. Versilok acrylic structuraladhesives were able to not only provide <strong>the</strong>ultraviolet resistance <strong>the</strong>y required, <strong>the</strong>yalso kept weight down, decreased productioncosts, provided a watertight seal, andimparted structural strength.Which adhesives were used in <strong>the</strong> assemblyof <strong>the</strong> solar power equipment?Howard: For <strong>the</strong> heliostat mirror modules,Versilok 204 was used to bond <strong>the</strong> cornerclips, <strong>the</strong> channels and <strong>the</strong> module supportdoublers. Versilok 506 was used tobond <strong>the</strong> special ABS plastic housings to<strong>the</strong> acrylic Fresnel lenses in <strong>the</strong> photovoltaicassemblies. Both <strong>the</strong>se applicationsrequired an adhesive that could not onlydeliver a strong bond, but could also act asa sealant and withstand harsh, hot environments.When <strong>the</strong> installation was dismantled30-years later, what did <strong>the</strong> contractor discover?Pugne: In 2009, <strong>the</strong> government decommissioned<strong>the</strong> <strong>Solar</strong> One installation and<strong>the</strong> solar panels had to be replaced. In dismantling<strong>the</strong> heliostat, <strong>the</strong> adhesives werefound to be intact after almost 30-years ofinstallation. The adhesive bonds had notbeen compromised, standing up to ultravioletrays and providing a watertight sealthat prevented corrosion for <strong>the</strong> life of <strong>the</strong>equipment.What is <strong>the</strong> growth potential for structuraladhesives in <strong>the</strong> solar industry?Pugne: Adhesives will gain more marketacceptance, as solar panel manufacturersbegin to understand <strong>the</strong> benefits of replacingmechanical fasteners with adhesivesand become more confident with using achemical method of joining, especially foraluminum racking systems.How will new types of structural adhesivesmeet <strong>the</strong> needs of <strong>the</strong> solar industry as itcontinues to develop?Pugne: Within <strong>the</strong> thin-film market, adhesiveswill provide protection against moistureand oxygen. O<strong>the</strong>r opportunities existin <strong>the</strong> attachment of thin-film materials tovarious substrates with no loss of durabilityor additional hardware required. Withmore than 60 years of experience designingand developing adhesives to satisfy awide variety of applications, LORD willcontinue to develop innovative adhesivesto meet <strong>the</strong> ever-changing requirements of<strong>the</strong> solar industry.14 – <strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 www.globalsolartechnology.com

Advanced wire sawing technology for solar photovoltaic cellswww.globalsolartechnology.com<strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 – 15

Market is murky on FiT cuts, natural disasters and renewed economic uncertaintyMarket is murkyon FiT cuts,natural disastersand renewedeconomicuncertaintyJon Custer-TopaiSlow going in 1H’11In many parts of <strong>the</strong> industrialized world,global economic growth has slowed incomparison to 2010 (Chart 1). Japan hasslipped back into a recession with industrialproduction (Chart 2) slowing and its“Purchasing Managers” index (Chart 3)pointing to continued contraction.Taiwan and China manufactured 59.4%(14,193 MW) of global cell productionin 2010 according to The InformationNetwork, and iSuppli expects China’s solarmodule production capacity is expected toreach 17.6 GW in 2011, or 62% of globalmanufacturing capacity.Taiwan and China’s (Charts 4 &5) “Purchasing Managers” indices areshowing slowing demand, and <strong>the</strong>ircurrencies (Charts 6 & 7) continue tostreng<strong>the</strong>n against <strong>the</strong> U.S. dollar. Recentlyrevised GDP projected growth rates fromHenderson Ventures (Chart 8) point toalmost 0 y/y GDP growth in Japan as aresult of <strong>the</strong> Fukushima earthquake, andall monthly Asian Purchasing Managers’indices growth (Chart 9) have contractedbased on a 3/12 rate of change.On a positive note, U.S. industrialproduction (Chart 10) and unemployment(Chart 11) are showing expansion, andcommodity prices (Chart 12) appear to bestabilizing.Looking back in history, onecan see that energy demand beganoutpacing U.S. population in 1960(Chart 13), and as additional countriesincrease transportation and technologyconsumption, energy demand will increase(Chart 14) proportionally.1Q’11 global solar supply chain (Chart15) grew 32% annually with crystallinecontinuing to dominate revenue growth,but both 3/12 and 12/12 rate of change(Chart 16) show weakening demand basedon preliminary publically traded earningscomposite data.Taiwan’s solar panel manufacturingmonthly revenue (Chart 17) confirmedfur<strong>the</strong>r softening based on highermanufacturing and transportationcosts, tightened incentive programs andincreased economic uncertainty.20110514Industrial Production - World% Change vs. One Year Earlier20110501Japan Industrial Production124120116112108104100969288848076726864601 4 7 10 1 4 7 10 1 4 7 10 1 4 7 10 1 4 7 10 1 4 7 10 1 4 7 10 1 4 7 10 1 403 04 05 06 07 08 09 10 11Calendar YearEconomist 5/2011 http://www.economist.com Output, prices and jobshttp://www.meti.go.jp/english/statistics/tyo/iip/h2afdlde.html#data_iipChart 1. Chart 2.16 – <strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 www.globalsolartechnology.com

Market is murky on FiT cuts, natural disasters and renewed economic uncertaintyreached $658 million in 25 deals—compared to $238 million in 4Q10 and$311 million in 1Q10.—Mercom CapitalGroupStorage & batteries<strong>Solar</strong> power industry will spend $953million (USD) on energy storage systemsin 2016, rising to $1.5 billion in 2018.—NanoMarketsCells modules panels<strong>Global</strong> photovoltaics module shipmentsdecreased by almost 10% from 6.4 GW in4Q10 to 5.8 GW in 1Q11.—IMS ResearchAlgatec <strong>Solar</strong>’s Canadian subsidiaryestablished 50,000 SF/50 MW photovoltaicmodule manufacturing facility in Ontario.Applied Sustainability Research Groupand <strong>the</strong> Sustainable Energy AppliedResearch Centre developed Open <strong>Solar</strong>Outdoors Test Field in Ontario.Arise Technologies• appointed Judson Whiteside to itsboard of directors.• temporarily reduced its German photovoltaiccell plant production dueto higher inventory levels and toughmarket conditions.BHEL and BEL are jointly buildingintegrated 250 MW solar photovoltaicmodules plant in ei<strong>the</strong>r in Karnataka orAndhra Pradesh.Bosch <strong>Solar</strong> Energy• expanded its photovoltaics productionto 150 MW to Vénissieux, France.• accomplished world record 19.6% efficiencyfor 4.73 Watt peak silicon PVcell.Canadian <strong>Solar</strong>• received 100 MW solar module supplydeal from Fire Energy Group, 81 MWsales agreement from Saferay and 97MW supply contract from GP Joule.• supplied 8 MW of solar modules toEOSOL Energies and <strong>the</strong> Caisse desdepots et consignations for a solarpower plant in Villeneuve de Marsan,Aquitaine, France.Daqo New Energy and JNE <strong>Solar</strong> arejointly building a 25 MW solar moduleproduction facility in Hamilton, Ontario,Canada.Day4 Energy reduced its workforce by 30jobs in Burnaby, B.C.Eclipsall is building 120,000 SF solar panelmanufacturing facility in Toronto.EMCORE received long-term supplyagreement with Space Systems/Loralfor multi-junction solar cells for SpaceSystems/Loral’s commercial satelliteprograms.Fraunhofer ISE achieved 20.2% efficiencyfor back-contact silicon solar cells usingscreen printing technology.Fudan University in China researchersdevised method to fabricate flexible andweavable solar cells using long fibers spunfrom flexible, light-weight, ultrastrong, andsemiconductive carbon nanotube fibers.<strong>Global</strong>Watt signed $2 million distributionagreement for commercial and mobilesolar panel systems for Texas installations.Helios <strong>Solar</strong> Works received $150,000in financing for purchase of roboticmanufacturing equipment at its factory in<strong>the</strong> Menomonee River Valley.Innotech <strong>Solar</strong> delivered 4.3 MWp solarphotovoltaic modules and engineeringservices for rooftop installation in Grenada,Spain.Jinko<strong>Solar</strong> appointed Ron Kenedi,president of Jinko<strong>Solar</strong> (U.S.) Inc.KISCO installed 65 MW production linefrom 3S Modultec.KYOCERA supplied 6 MWmulticrystalline silicon solar modules fora large-scale solar power plant near Turin,Italy.LDK <strong>Solar</strong> expects China’s demand toreach 3-4 GW in 2012.MIT researchers developed photovoltaiccell based on organic molecules thatharnesses <strong>the</strong> energy of infrared light whileallowing visible light to pass through.Moser Baer planned crystalline-basedsolar cells and thin film solar cell facilityoutside of Hyderabad was cancelled byAndhra Pradesh government.PLG Power is building 120 MW solar cellmanufacturing facility in Nashik, India.Pufin French subsidiary is building 20MW module production facility in SaintEtienne, France.PV Evolution Labs launched fast-turnaround3rd party flash testing service inBerkeley, CA.Qsolar sold 50 MW of solar panels withSpraytek79 <strong>Technology</strong> to Commercial<strong>Solar</strong> Design for $74.5 million.SANYO and Westburne (Rexel CanadaElectrical) entered solar PV moduledistribution alliance across Canada.Silfab opened 90 MW PV modulemanufacturing facility in Mississauga,Ontario. received 9.3 MW module orderfrom Agris <strong>Solar</strong> Cooperative Inc.Siliken began offering 25-year linearpower guarantee.<strong>Solar</strong>ia named Marco Garcia, COO andBob Zapotosky, CFO.<strong>Solar</strong>PA and <strong>Solar</strong> Power Industriesjointly deployed nanocrystal coating onsolar cells to enhance solar cell efficiencyby 11.5%.SoloPower• is spending $340 million to build asolar plant to North Portland, Oregon.• abandoned $11 million incentive pack-20110505China Yuan vs. U.S. Dollar20110505GDP GrowthConstant $ Growth Rates Converted @ Constant Exchange RatesExchange Rate Yuan/US$8.38.28.187.97.87.77.67.57.47.37.27.171% stronger vs US$ in 2010 vs 20096.96.86.76.66.51 2 3 4 5 6 7 8 9101 121 2 3 4 5 6 7 8 91011121 2 3 4 5 6 7 8 9101 121 2 3 4 5 6 7 8 9101 121 2 3 4 5 6 7 8 9101 121 2 3 4 5 6 7 8 9101 121 2 3 4 5 605 06 07 08 09 10 112009 2010 2011 2012 2013World -1.8 4.0 3.4 4.0 3.8USA -2.6 2.9 2.9 3.2 2.8EU -4.2 1.7 1.7 1.8 2.0Japan -5.2 4.0 0.2 3.2 1.7Four Tigers -0.8 7.0 4.5 5.0 4.6China 9.1 10.3 9.0 8.7 8.5CALENDAR YEARhttp://research.stlouisfed.org/fred2/categories/15Henderson Ventures 5/2011www.hendersonventures.comChart 7. Chart 8.18 – <strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 www.globalsolartechnology.com

Market is murky on FiT cuts, natural disasters and renewed economic uncertaintyage tied to Wilsonville.Sunrise <strong>Global</strong> <strong>Solar</strong> Energyaccomplished 19.2% efficiency for massproduced monocrystalline silicon solar cellusing Schmid GmbH technology.Suntech Power Holdings• introduced third production shift atits photovoltaic panel manufacturingfacility in Goodyear, Arizona.• received 100 MW/2 yr polycrystallinemodule supply contract fromSunBorne for turnkey solar powerplants in India.• plans to add at least 9.5 GW of newmanufacturing lines in 2011.SVTC Technologies received $25M grantfrom U.S. DOE to build a photovoltaicmanufacturing development facility.Total acquired 60% of SunPower.Trina <strong>Solar</strong>• and <strong>the</strong> Australian National Universityentered n-type silicon solar cellresearch collaboration.• downwardly adjusted its 1Q11 solarmodule shipment forecast to 320-322MW.• entered 130 MW sales agreement withEPC Mohring Energie GmbH.• received 40 MW PV module supplycontract from RF Industries.• opened a sales and business developmentoffice in Sydney, Australia.Uni-<strong>Solar</strong> is setting up a manufacturingplant in LaSalle, Ontario, to take advantageof <strong>the</strong> province’s FIT program.Yingli Green Energy• established Sou<strong>the</strong>ast Asian headquartersin Singapore.• entered into exclusive agent agreementand 10 MW PV module distributioncontract, with YHS Co.EMS & assemblyDC Electronics is adding 12,500 SF to its30,000 SF facility in San Jose, CA.Flextronics• and SunPower dedicated new solarpanel manufacturing plant in Milpitas,CA.• Malaysia facility received 270MW/yr solar panel contract manufacturingorder from MEMC ElectronicMaterials.Dr. Dongkai Shangguan was appointed toSustainable <strong>Technology</strong>’s advisory board.Solon sold its stake in ml&s to HydraulikNord.Worldwide Energy & Manufacturingappointed Jeff Watson CEO.IntegrationAmerican Capital Energy built 18.3 MWsolar project for Cape & Vineyard ElectricCooperative in Cape Cod and Martha’sVineyard.Amonix built 2 MW AC Nameplate powerplant at University of Arizona’s Science and<strong>Technology</strong> Park.AREVA <strong>Solar</strong> is installing a 44 MW solar<strong>the</strong>rmal augmentation project at 750 MWcoal-fired power station in Queensland,Australia.Atlantic Green Power and Invenergy aredeveloping 18 MW solar project in New201105021.91.40.9Asian Purchasing Managers' Indices3/12 rate of change0.411 2 5 8 11 2 5 8 11 2 5 8 11 2 5 8 11 2 5 8 11 2 5 8 11 2 5 8 11 2 503 04 05 06 07 08 09 10 11Source: Custer Consulting Group"0" Growth China TaiwanS KoreaJapanCALENDAR YEAR201104271041009692888480767268646056(Seasonally Adjusted)U.S. Industrial ProductionIndex (2007=100)1 4 71014 7101 4 71014 7101 4 71014 7101 4 7101 47101 4 7101 47101 4 71014 7101 4 71014 7101 4 7101 47101 4 7101 47101 4 7101 47101 4 7101 490 91 92 93 94 95 96 97 98 99 00 01 02 03 04 05 06 07 08 09 10 11Calendar Yearwww.federalreserve.gov/releases/g17/table1_2.htmChart 9. Chart 10.20110401U.S. Civilian Unemployment Rate20110514Oil vs. Copper Prices11 %109876Highest sinceApril 198313512010590756045OilCopper150 US$/Barrel 0Speculative buyingSpot Oil Prices - US$ & EurosW Texas Intermediate CrudeUS$/pound54325431 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 189 90 91 92 93 94 95 96 97 98 99 00 01 02 03 04 05 06 07 08 09 10 11CALENDAR YEARConference Boardwww.conference-board.org/data/bcicountry.cfm?cid=1301501 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 1 7 100 01 02 03 04 05 06 07 08 09 10 11CALENDAR YEARhttp://research.stlouisfed.org/fred2/data/OILPRICE.txthttp://futures.tradingcharts.com/chart/CP/B9Chart 11. Chart 12.1www.globalsolartechnology.com<strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 – 19

Market is murky on FiT cuts, natural disasters and renewed economic uncertaintyJersey.Atlantic Wind & <strong>Solar</strong>• CEO, Pierre Cousin resigned.• appointed Mark Holcombe and Dr. LucDuchesne to its board of directors.Avidan Management completed 4.26 MWrooftop solar system in New Jersey.AZUR SOLAR opened head office,visitor and distribution center in Slough,Berkshire, UK.Boeing South Carolina plant added 2.6MW thin-film panel rooftop solar system.Borrego installed 1 MW rooftop solarpanel system for NewAge Industries inSouthampton, Pennsylvania.BrightSource solar received $1.6billion loan guarantee from U.S. EnergyDepartment for proposed 392 MWIvanpah (California) solar complex.California Independent System Operatorlaunched new <strong>Solar</strong> Today web graph thatdepicts real-time data of solar energy beinggenerated on <strong>the</strong> ISO wholesale power grid.CBD Energy, Datang Renewable Powerand Baoding Electric formed newcorporate entity, <strong>the</strong> AusChina EnergyGroup.Chevron Mining and Chevron<strong>Technology</strong> Ventures built 1 MWdemonstration plant in New Mexico.Clear <strong>Solar</strong> added a Dataweave ERPsystem.Cogentrix Energy received $90.6 millionconditional loan guarantee from U.S.Energy Department to build 30 MWAlamosa solar generating project inColorado.Community Energy <strong>Solar</strong> and ExelonGeneration closed 15-year agreementfor purchase of power and renewableenergy credits from 6 MW solar project inLancaster County, Penn.Conergy• is building 12.4 MW solar park inNakhon Pathom province, Thailand.• installed 1.75 MW power plant on <strong>the</strong>Canary Islands.• Constellation Energy• developed 4.5 MW solar powersystem with Holyoke Gas & Electric inHolyoke, Mass.• built 5.38 MW solar panel system (2ndlargest solar rooftop installation in <strong>the</strong>world) on Toys R Us distribution centerin Flanders, New Jersey.• Bought 30 MW Sacramento, California,solar project from Belectric.Cupertino Electric completed 1.26 MWsolar PV system installation at MountainView School.DRI Energy completed 1.24 MW solardeployment in San Jose, California.Duke Energy Renewables acquired 1 MWsolar farm at North Carolina elementaryschool.EDF Energies Nouvelles Réparties sold itsstake in Tenesol to Total.Efektim• hired Ondrej Slavík as director of service.• started construction on FVE Kresandraand FVE Power Plant 1 photovoltaicpower plants in Slovakia.Egypt is building 100 MW solarphotovoltaic power plant in Kom Ombo,Aswan.eIQ Energy’s Parallel <strong>Solar</strong> <strong>Technology</strong>completed 1.2 MW array in Coalinga, Calif.Energix Renewable Energy raised NIS 146million in IPO.Enfinity completed two photovoltaicprojects totaling 18.2 MW in Les Mées,France.First <strong>Solar</strong> and China PowerInternational New Energy Holding arejointly collaborating on solar photovoltaicprojects in China, U.S. and o<strong>the</strong>rinternational markets.Fotowatio is building 30 MW solar plantin Webberville, Texas.Gehrlicher completed 3.1 MW rooftopsolar PV systems in Wittenberg, Germany.Innergex Renewable Energy acquiredrights to develop Enfinity NV 27 MWACStardale photovoltaic solar project for$11.1 million.Innotech <strong>Solar</strong> secured NOK45m(€5.72m) contract to supply photovoltaicmodules and engineering services to anundisclosed European utility company fora power plant in Spain.Lanco plans to scale up 5 MW solar powergeneration plant in Gujarat to 35 MW by<strong>the</strong> end of 2011.Lincoln Renewable Energy concludedpower sales and project finance agreementwith Macquarie Energy for 10 MW solarphotovoltaic project in Fairfield Townshipin Cumberland County, New Jersey.Macy’s added 3.5 MW solar power systemon <strong>the</strong> roof of its online fulfillment centerin Goodyear, AZ.Natuzzi Group added five rooftopphotovoltaic systems totaling 4.5 MW inPuglia and Basilicata, Italy.NJR Clean Energy Ventures built 3.6 MWsolar project in Manalapan, New Jersey.Nor<strong>the</strong>rn California Power Agency,Lightbeam and Gridley built 1 MWphotovoltaic array on Highway 99.NTE Energy named Melissa HouskampCFO.OCI <strong>Solar</strong> Power LLC/CornerStoneHolmdel constructed 4.8 MW solar fieldin Holmdel, New Jersey.OPDE completed a total of 36.43 MW ineight farms in Italy and Spain in 1Q11.Partners Group spent 276 million-euro($399 million) to acquire 71 MW solar2011050120110501Energy DemandTotal & Per CapitaDeloitte Review 7/09Earthtrends 2008Chart 13. Chart 14.20 – <strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 www.globalsolartechnology.com

Market is murky on FiT cuts, natural disasters and renewed economic uncertaintyphotovoltaic plant in Rovigo, Italy.Pegasus Energy plans to build a 400 MWphotovoltaic solar power plant in AlamedaCounty, California.Phoenix <strong>Solar</strong>• completed 12 MW solar PV park inFrance.• is building 3.5 MW solar park for SaudiArabian Oil Company.PLG Power signed power purchaseagreement with Gujarat Urja Vikas Nigamfor 40 MW of solar power.Public Service Electric and Gas Companyand Matrix Development Group completed2.8 MW rooftop solar installations in PerthAmboy, NJ.Q-Cells founded Q-Cells Meister Club(QMC) to serve Japanese residential marketwith integrated photovoltaic solutions.REC completed 1.8 MW PV system forIkea in Tejon, California.S.A.G. <strong>Solar</strong>strom completed 12 MWpphotovoltaic project in Nor<strong>the</strong>rn Italy.Scatec <strong>Solar</strong> completed 4 MW Italian PVplant in Puglia, Italy.Silfab Ontario and Alderville FirstNation are building a 5 MW solar farm inOntario.Solaire Generation installed 3.6 MW(largest corporate) solar parking powerplant in U.S.<strong>Solar</strong> Thin Films changed its business fromsale of turnkey factories for production ofthin film solar modules to establishing,financing, managing and syndicating solarfarms.<strong>Solar</strong> Trust of America formed JV with<strong>Solar</strong>Hybrid.Solis Partners completed 1.2 MW rooftopPV installation in Freehold, N.J for ShorePoint Distributing.SOLON completed 2.7 MW in solar systemfor Arizona’s Paradise Valley UnifiedSchool District.Solyndra and Interservice Uzunoviinstalled 1 MW solar system on Biometrooftop in Sevlievo, Bulgaria.Spain is spending 55 million euro toconstruct 47.5 MW solar power facility forLucainena de las Torres.SPG <strong>Solar</strong>• appointed Tom Sandman (formerly ofGE) as Sr VP and CFO and Lin JohnsonGeneral, Counsel and VP.• completed 3MW-DC solar PV planton redeveloped military facility inSacramento, California.Spire <strong>Solar</strong> Systems constructed 2MW at Berkshire School in Sheffield,Massachusetts.SunPower• completed 1MW ground-mountedsolar power system in Tucson, Arizona.• installed 1.7 MW solar power systemfor Rancho California Water District.• received $1.187 bln federal loan guaranteeto finance 250-MW solar powerplant in California Valley <strong>Solar</strong> Ranchin San Luis Obispo County.• built 5MW farm at Kalaeloa in WestOahu, Hawaii.Tata Power commissioned 3MW solarpower plant in Maharashtra, India.TerraSmart appointed Colleen Brennan asVP of marketing and public relations.Tigo Energy raised $10 million in equity20110522<strong>Global</strong> "<strong>Solar</strong>/Photovoltaic Foodchain" Growth1Q'11 vs. 1Q'10 (Preliminary estimate)20100918Total Industry3220110522<strong>Global</strong> <strong>Solar</strong>/Photovoltaic GrowthTotal Industry based upon 60 Company broad sample3/12 & 12/12 Rate of ChangeVertically IntegratedCells, Modules, PanelsThin Film Processes024321.52 Rate of Growth (1.0=no growth) 12/12 3/12Zero GrowthThin Film Process EquipCrystalline Semiconductor Processes121021O<strong>the</strong>r Process Equip38Materials70.5Inverters & Power Supplies48Batteries & StorageInstallations & End Applications7190 20 40 60 80 100 120% ChangeUS$ equivalent at fluctuating exchange; based upon industry composites including acquisitions01 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 207 08 09 10 11CALENDAR YEARChart 15. Chart 16.20110511Taiwan <strong>Solar</strong>/Photovoltaic Panel CompaniesComposite of 17 ManufacturersNT$ billions201816141210864202010/2009 RevenueUp 80%1357911135791113579111357911135791113579111357911135791113579111357911135791113500 01 02 03 04 05 06 07 08 09 10 11CALENDAR YEARBig Sun Energy <strong>Technology</strong>, Daxon, Del<strong>Solar</strong>, e_TON <strong>Solar</strong> Tec, Eversol, Gintech, Green Energy <strong>Technology</strong> (GET),Ligitek, Motech, Neo <strong>Solar</strong> Power, Phoenixtec Power Co (PPC), Precision Silicon, Sino-American Silicon Products,Sonartech, Sysgration, Tyntek, Wafer WorksChart 17.20100513Subcontracting in <strong>Solar</strong> Manufacturing Industry<strong>Solar</strong> Module EMS Production ForecastGW of <strong>Solar</strong> Panels5.04.14.03.03.02.22.01.81.11.00.40.02009 2010 2011 2012 2013 2014iSuppli 4/10Chart 18.www.globalsolartechnology.com<strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 – 21

Market is murky on FiT cuts, natural disasters and renewed economic uncertaintycapital and secured an accounts-receivableline for up to an additional $10 million.Total acquired Tenesol’s operations.Unirac achieved ISO 9001:2008 QMS andISO 14001:2004 EMS certifications.United <strong>Solar</strong> completed 1.1 MW solarpower system on <strong>the</strong> rooftop of a logisticscenter in Marignane, France.Vermont Air National Guard base added2.2 MW solar project in South Burlington,Vermont.Western Massachusetts ElectricCompany constructed 2.2 MW solarenergy facility in Springfield.Youil Renewable Energy is building40 MW solar plant in E.B. Magalona,Philippines.Inverters & power suppliesJapan-made PV inverter-use aluminumcapacitor supply is not expected to easeuntil 3Q11.—NichidenboAdvanced Energy• is celebrating 30 years in business.• solar inverter achieved record 98% efficiency.Delta Electronics is building solar powerswitching supply plant in Chennai, India,which is scheduled to begin production inApril 2012.Emerson provided utility-scale powerinverters for 30 MW solar power plant inWebberville, Texas.Enecsys• revealed details of novel solar inverterarchitecture, which eliminates electrolyticcapacitors to increase reliability.• received £25 million ($41 million) inSeries B equity financing.Energy Conversion• cut 300 jobs.• named Jay Knoll as its interim president.• initiated a search for a permanent CEOto replace Mark Morelli.Harland Simon and Aston Energy teamedup on EnergySolis series grid-connectedphotovoltaic inverter.IXYS introduced rugged 500 V and 600 VPolarP3 Power MOSFETs.Power-One added two Hitachi (Sigma)G5 high-speed SMT assembly systems inCamarillo, California.Satcon appointed Aaron Gomolakexecutive VP, CFO and treasurer.SMA <strong>Solar</strong> <strong>Technology</strong> appointed Pierre-Pascal Urbon CEO.<strong>Solar</strong>Bridge Technologies namedCelestica its CEM for volume productionof Pan<strong>the</strong>onTM microinverters.<strong>Solar</strong>Edge added a PV inverter productionline at Flextronics Newmarket, Ontario,factory.Solectria Renewables expanded capacityat its Lawrence, Mass., facility to 800 MW.Sustainable Energy and Eclipsall Energyentered 10 MW collaboration on solarpower “kits” based on SUNERGY invertersfor North American markets.Tigo Energy received $10 million inadditional equity capital from GenerationInvestment Management.Materials & componentsDye sensitized cell panel and materialsmarkets are expected to reach US $1.9Billion by 2016.—NanoMarketsInternational quotes for PV silverconductive paste rose 20% from US$1,500-1,600/kg in January 2011 to US$1,900/kgin May 2011.3M named George Buckley COO.Aldrich Materials Science and Agfabegan jointly producing and distributingOrgacon conductive polymers for use inorganic photovoltaics.Applied Nanotech Holdings opened solarinks pilot manufacturing line in Austin,Texas.Applied Seals North America openedapplications and design center at its SiliconValley Headquarters.Asia Polymer is building 120,000 MTethylenevinyle acetate plant in KaohsiungCounty, Taiwan.Avantor Performance Materialsappointed Sushil Mehta executive VP andBrian Wilson executive VP of Operations.Bosch appointed Eric Daniels regionalpresident of <strong>Solar</strong> Energy.Bridgestone added new productionethylene vinyl acetate film line in Poland.Centrosolar commissioned its first Asiananti-reflective coating line in Huzhou,China.Dow Chemical named Targray its globaldistributor for its ENLIGHT polyolefinencapsulant films.Dow Corning named Robert Hansen CEO.DuPont introduced low-silver Solamet®PV pastes.Giga <strong>Solar</strong> Materials expects its globalmarket share for PV aluminum paste torise from 27% in 2010 to 40% in 2011.Hangzhou First PV Material namedAstenik <strong>Solar</strong> its exclusive Canadiandistributor.Henkel released hot melt adhesive/sealantthat allows immediate handling of solarmodules.LDK <strong>Solar</strong> is investing $35 million toexpand silane gas manufacturing in XinyuCity, Jiangxi Province, to 2,000 MT .Marubeni became Innovalight’s distributorfor silicon ink in Japan.O-I inaugurated new photovoltaic glassplant in Béziers, France.Phononic Devices appointed former First<strong>Solar</strong> president Bruce Sohn to its board ofdirectors.20110223Photovoltaic Value Stack (Crystalline Silicon)Module Cost (2008 Figures)20110501PV Inverter Shipments100%80%60%40%20%0%iSuppli 2011ModuleCost21%15%19%15%15%15%PolysiliconIngots & WaferCellModuleO<strong>the</strong>r ComponentsInstallationAccording to iSuppli, <strong>the</strong> EMS productionvalue for solar modules was 1.1 gigawatts(GW) in 2010 with <strong>the</strong> median module costingaround $1.86/watt (wholesale) for a total of $2billion out of total worldwide moduleproduction for 17.7 GW values at $33 billion.A fur<strong>the</strong>r breakdown of module costs based2008 production cost at a median of $2.11/wattare for a 50 MW/year production line:- <strong>the</strong> wafer costs $1.08/W- changing <strong>the</strong> wafer into a cell costs $0.40-45- changing <strong>the</strong> cell into a module costsano<strong>the</strong>r $0.40-45Module cost = $2.11/W at 85% cumulativeyield. Source: PJC Poly Si Supply & DemandAnalysis8.07.06.05.04.03.02.01.0GWpSystem installations will reach22.4GWp in 2011, while shipmentsof PV inverters will hit 24.5 GWp0.01 2 3 4 1 2 3 4 1 2 3 409 10 11Digitimes Research 4/11Chart 19. Chart 20.22 – <strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 www.globalsolartechnology.com

Market is murky on FiT cuts, natural disasters and renewed economic uncertaintySAGE added a glass manufacturing plantin Faribault, Minn.Solutia opened a commercial-gradeVistasolar EVA encapsulant manufacturingfacility in Suzhou, China.Sumitomo Chemical is increasing itsJapanese production capacity for highlyfunctional resins used for manufacturingsolar cells in October to nearly 30,000 tons/year.Taiflex Scientific received DuPonttechnology licensing for PV back sheets.Teknek introduced Ultracleen range ofcleaning roller for flat panel display, solarphotovoltaic, touch panel, and o<strong>the</strong>r thinfilms.Toyobo is investing 7 billion yen to increaseprotective film production for solar cellsand touch panels.Process equipmentAmtech appointed Dr. James Hwang asCTO and Dr. SooKap Hahn to board ofdirectors.BTU International named Jack Antouniandirector of operations.Centro<strong>the</strong>rm Photovoltaics and KineticsGermany constructed an almost fullyintegrated solar module factory in Algeria.DEK <strong>Solar</strong> PVP1200 print platform wasused by Institute for <strong>Solar</strong> Energy ResearchHamelin to accomplish record 19.4%crystalline silicon cell efficiency.GT <strong>Solar</strong> monocast silicon materialachieved average cell efficiencies of 18.8%with highest efficiencies exceeding 19%on monocast silicon material as testedby Researchers at Georgia Institute of<strong>Technology</strong>.J.v.G. Thoma group received contract forset-up of a turnkey PV production line inIndia.MAG delivered turnkey 30 MWphotovoltaic module system to <strong>Solar</strong>-Energy sp.z o.o. in Bozepole Wielkie,Poland.Meyer Burger acquired Roth & Rau.Rite Track hired John Marcheschi as VP ofsales.Schmid Group delivered 1000th wetprocessing system made in China.R&DOerlikon <strong>Solar</strong> and <strong>the</strong> Institute of Physics’photovoltaic group at <strong>the</strong> Academy ofSciences of <strong>the</strong> Czech Republic discoveredthat ‘Swiss cheese’ design enables thin filmsilicon solar cells with potential for higherefficiencies.University of Missouri engineer developedflexible solar sheet that captures more than90% of available light.Silicon ingot waferApplied Materials received 2.5 GW orderfor HCT B5TM wire saws from GCL-PolyEnergy.AUO Crystal broke ground on 250MW solar monocrystalline ingots andmonocrystalline wafer plant in CentralTaiwan Science Park’s Houli base.Comtec <strong>Solar</strong> Systems is targeting 1,400MW output capacity for 2011.20100329Cost Breakdown of Single String Inverter forResidential Application - 200920101216Demand Increase in 2010 by Inverter Power LevelMagnetic ComponentsPower Electronic Compo>500 kWBoard & Electronics31%10%12%101-500 kW19%36-100 kW23%5%Enclosure10-35 kWTest