download the PDF - Global Solar Technology

download the PDF - Global Solar Technology

download the PDF - Global Solar Technology

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

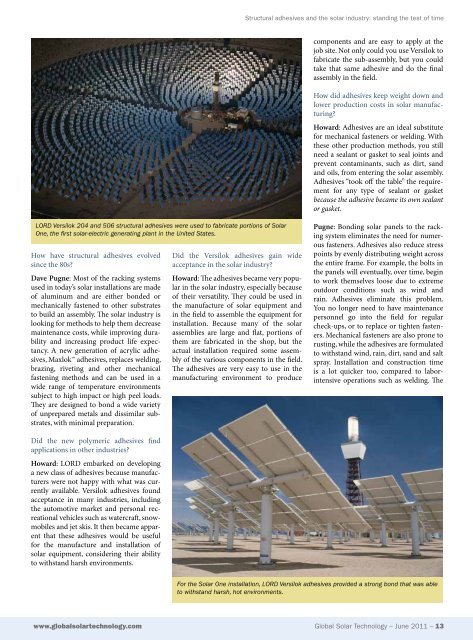

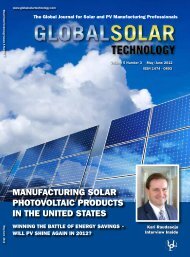

Structural adhesives and <strong>the</strong> solar industry: standing <strong>the</strong> test of timecomponents and are easy to apply at <strong>the</strong>job site. Not only could you use Versilok tofabricate <strong>the</strong> sub-assembly, but you couldtake that same adhesive and do <strong>the</strong> finalassembly in <strong>the</strong> field.How did adhesives keep weight down andlower production costs in solar manufacturing?Howard: Adhesives are an ideal substitutefor mechanical fasteners or welding. With<strong>the</strong>se o<strong>the</strong>r production methods, you stillneed a sealant or gasket to seal joints andprevent contaminants, such as dirt, sandand oils, from entering <strong>the</strong> solar assembly.Adhesives “took off <strong>the</strong> table” <strong>the</strong> requirementfor any type of sealant or gasketbecause <strong>the</strong> adhesive became its own sealantor gasket.LORD Versilok 204 and 506 structural adhesives were used to fabricate portions of <strong>Solar</strong>One, <strong>the</strong> first solar-electric generating plant in <strong>the</strong> United States.How have structural adhesives evolvedsince <strong>the</strong> 80s?Dave Pugne: Most of <strong>the</strong> racking systemsused in today’s solar installations are madeof aluminum and are ei<strong>the</strong>r bonded ormechanically fastened to o<strong>the</strong>r substratesto build an assembly. The solar industry islooking for methods to help <strong>the</strong>m decreasemaintenance costs, while improving durabilityand increasing product life expectancy.A new generation of acrylic adhesives,Maxlok adhesives, replaces welding,brazing, riveting and o<strong>the</strong>r mechanicalfastening methods and can be used in awide range of temperature environmentssubject to high impact or high peel loads.They are designed to bond a wide varietyof unprepared metals and dissimilar substrates,with minimal preparation.Did <strong>the</strong> Versilok adhesives gain wideacceptance in <strong>the</strong> solar industry?Howard: The adhesives became very popularin <strong>the</strong> solar industry, especially becauseof <strong>the</strong>ir versatility. They could be used in<strong>the</strong> manufacture of solar equipment andin <strong>the</strong> field to assemble <strong>the</strong> equipment forinstallation. Because many of <strong>the</strong> solarassemblies are large and flat, portions of<strong>the</strong>m are fabricated in <strong>the</strong> shop, but <strong>the</strong>actual installation required some assemblyof <strong>the</strong> various components in <strong>the</strong> field.The adhesives are very easy to use in <strong>the</strong>manufacturing environment to producePugne: Bonding solar panels to <strong>the</strong> rackingsystem eliminates <strong>the</strong> need for numerousfasteners. Adhesives also reduce stresspoints by evenly distributing weight across<strong>the</strong> entire frame. For example, <strong>the</strong> bolts in<strong>the</strong> panels will eventually, over time, beginto work <strong>the</strong>mselves loose due to extremeoutdoor conditions such as wind andrain. Adhesives eliminate this problem.You no longer need to have maintenancepersonnel go into <strong>the</strong> field for regularcheck-ups, or to replace or tighten fasteners.Mechanical fasteners are also prone torusting, while <strong>the</strong> adhesives are formulatedto withstand wind, rain, dirt, sand and saltspray. Installation and construction timeis a lot quicker too, compared to laborintensiveoperations such as welding. TheDid <strong>the</strong> new polymeric adhesives findapplications in o<strong>the</strong>r industries?Howard: LORD embarked on developinga new class of adhesives because manufacturerswere not happy with what was currentlyavailable. Versilok adhesives foundacceptance in many industries, including<strong>the</strong> automotive market and personal recreationalvehicles such as watercraft, snowmobilesand jet skis. It <strong>the</strong>n became apparentthat <strong>the</strong>se adhesives would be usefulfor <strong>the</strong> manufacture and installation ofsolar equipment, considering <strong>the</strong>ir abilityto withstand harsh environments.For <strong>the</strong> <strong>Solar</strong> One installation, LORD Versilok adhesives provided a strong bond that was ableto withstand harsh, hot environments.www.globalsolartechnology.com<strong>Global</strong> <strong>Solar</strong> <strong>Technology</strong> – June 2011 – 13