MODULAR RACK & PINION SYSTEM - Andantex USA Inc.

MODULAR RACK & PINION SYSTEM - Andantex USA Inc.

MODULAR RACK & PINION SYSTEM - Andantex USA Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>MODULAR</strong> <strong>RACK</strong> & <strong>PINION</strong> <strong>SYSTEM</strong><br />

General Information<br />

The units can be mounted in any position,<br />

and are provided with a contact cable for<br />

synchronization with machine operation. The<br />

lubricant dispensing rate can be adjusted during<br />

operation by simply adjusting the selector<br />

switches. The translucent housing allows for<br />

easy inspection of the lubricant level, and the<br />

units have an LED that can be set to flash every<br />

15 to 20 seconds indicating the system is in<br />

working order. The unit is rated for temperatures<br />

up to 130° F, and maximum pressure of 50 PSI.<br />

This unit is designed to feed a single point and<br />

is not intended as a multi point lubricator.<br />

The lubricator is supplied with a cover to<br />

protect against dirt, and moisture, and in all<br />

cases, the cover must be installed to ensure<br />

the intrinsic safety rating of the unit. The<br />

service life of the battery is 1 year.<br />

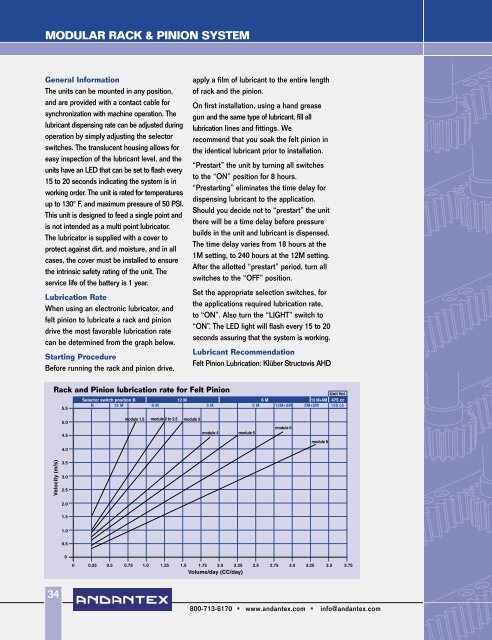

Lubrication Rate<br />

When using an electronic lubricator, and<br />

felt pinion to lubricate a rack and pinion<br />

drive the most favorable lubrication rate<br />

can be determined from the graph below.<br />

Starting Procedure<br />

Before running the rack and pinion drive,<br />

apply a film of lubricant to the entire length<br />

of rack and the pinion.<br />

On first installation, using a hand grease<br />

gun and the same type of lubricant, fill all<br />

lubrication lines and fittings. We<br />

recommend that you soak the felt pinion in<br />

the identical lubricant prior to installation.<br />

“Prestart” the unit by turning all switches<br />

to the “ON” position for 8 hours.<br />

“Prestarting” eliminates the time delay for<br />

dispensing lubricant to the application.<br />

Should you decide not to “prestart” the unit<br />

there will be a time delay before pressure<br />

builds in the unit and lubricant is dispensed.<br />

The time delay varies from 18 hours at the<br />

1M setting, to 240 hours at the 12M setting.<br />

After the allotted “prestart” period, turn all<br />

switches to the “OFF” position.<br />

Set the appropriate selection switches, for<br />

the applications required lubrication rate,<br />

to “ON”. Also turn the “LIGHT” switch to<br />

“ON”. The LED light will flash every 15 to 20<br />

seconds assuring that the system is working.<br />

Lubricant Recommendation<br />

Felt Pinion Lubrication: Klüber Structovis AHD<br />

Rack and Pinion lubrication rate for Felt Pinion<br />

34<br />

800-713-6170 • www.andantex.com • info@andantex.com