MODULAR RACK & PINION SYSTEM - Andantex USA Inc.

MODULAR RACK & PINION SYSTEM - Andantex USA Inc.

MODULAR RACK & PINION SYSTEM - Andantex USA Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

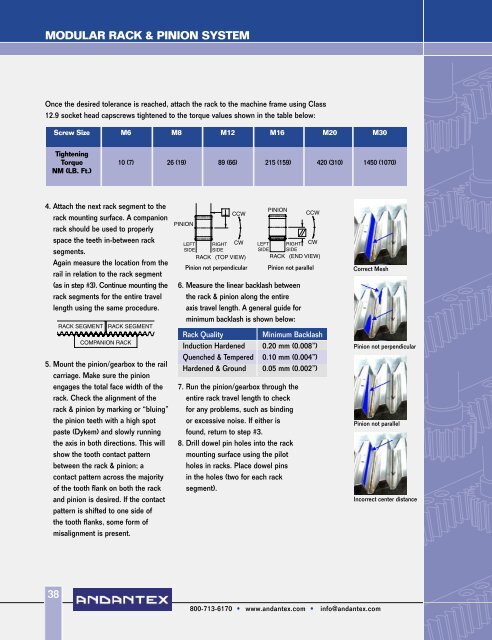

<strong>MODULAR</strong> <strong>RACK</strong> & <strong>PINION</strong> <strong>SYSTEM</strong><br />

Once the desired tolerance is reached, attach the rack to the machine frame using Class<br />

12.9 socket head capscrews tightened to the torque values shown in the table below:<br />

Screw Size M6 M8 M12 M16 M20 M30<br />

Tightening<br />

Torque 10 (7) 26 (19) 89 (66) 215 (159) 420 (310) 1450 (1070)<br />

NM (LB. Ft.)<br />

4. Attach the next rack segment to the<br />

rack mounting surface. A companion<br />

rack should be used to properly<br />

space the teeth in-between rack<br />

segments.<br />

Again measure the location from the<br />

rail in relation to the rack segment<br />

(as in step #3). Continue mounting the<br />

rack segments for the entire travel<br />

length using the same procedure.<br />

5. Mount the pinion/gearbox to the rail<br />

carriage. Make sure the pinion<br />

engages the total face width of the<br />

rack. Check the alignment of the<br />

rack & pinion by marking or “bluing”<br />

the pinion teeth with a high spot<br />

paste (Dykem) and slowly running<br />

the axis in both directions. This will<br />

show the tooth contact pattern<br />

between the rack & pinion; a<br />

contact pattern across the majority<br />

of the tooth flank on both the rack<br />

and pinion is desired. If the contact<br />

pattern is shifted to one side of<br />

the tooth flanks, some form of<br />

misalignment is present.<br />

Pinion not perpendicular<br />

Pinion not parallel<br />

6. Measure the linear backlash between<br />

the rack & pinion along the entire<br />

axis travel length. A general guide for<br />

minimum backlash is shown below:<br />

Rack Quality<br />

Minimum Backlash<br />

Induction Hardened 0.20 mm (0.008”)<br />

Quenched & Tempered 0.10 mm (0.004”)<br />

Hardened & Ground 0.05 mm (0.002”)<br />

7. Run the pinion/gearbox through the<br />

entire rack travel length to check<br />

for any problems, such as binding<br />

or excessive noise. If either is<br />

found, return to step #3.<br />

8. Drill dowel pin holes into the rack<br />

mounting surface using the pilot<br />

holes in racks. Place dowel pins<br />

in the holes (two for each rack<br />

segment).<br />

Correct Mesh<br />

Pinion not perpendicular<br />

Pinion not parallel<br />

<strong>Inc</strong>orrect center distance<br />

38<br />

800-713-6170 • www.andantex.com • info@andantex.com