Sigma C4 Controller - Sigma Systems Corporation

Sigma C4 Controller - Sigma Systems Corporation

Sigma C4 Controller - Sigma Systems Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

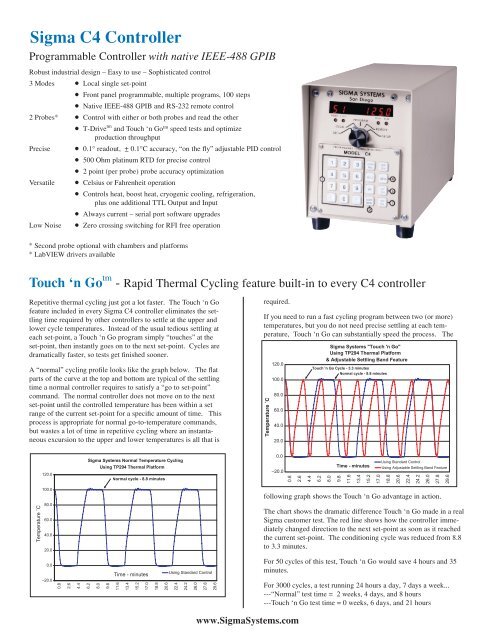

<strong>Sigma</strong> <strong>C4</strong> <strong>Controller</strong><br />

Programmable <strong>Controller</strong> with native IEEE-488 GPIB<br />

Robust industrial design – Easy to use – Sophisticated control<br />

3 Modes • Local single set-point<br />

• Front panel programmable, multiple programs, 100 steps<br />

• Native IEEE-488 GPIB and RS-232 remote control<br />

2 Probes* • Control with either or both probes and read the other<br />

• T-Drive tm and Touch ‘n Go tm speed tests and optimize<br />

production throughput<br />

Precise • 0.1° readout, ± 0.1°C accuracy, “on the fly” adjustable PID control<br />

• 500 Ohm platinum RTD for precise control<br />

Versatile<br />

Low Noise<br />

• 2 point (per probe) probe accuracy optimization<br />

• Celsius or Fahrenheit operation<br />

• Controls heat, boost heat, cryogenic cooling, refrigeration,<br />

plus one additional TTL Output and Input<br />

• Always current – serial port software upgrades<br />

• Zero crossing switching for RFI free operation<br />

* Second probe optional with chambers and platforms<br />

* LabVIEW drivers available<br />

Touch ‘n Go tm - Rapid Thermal Cycling feature built-in to every <strong>C4</strong> controller<br />

Repetitive thermal cycling just got a lot faster. The Touch ‘n Go<br />

feature included in every <strong>Sigma</strong> <strong>C4</strong> controller eliminates the settling<br />

time required by other controllers to settle at the upper and<br />

lower cycle temperatures. Instead of the usual tedious settling at<br />

each set-point, a Touch ‘n Go program simply “touches” at the<br />

set-point, then instantly goes on to the next set-point. Cycles are<br />

dramatically faster, so tests get finished sooner.<br />

A “normal” cycling profile looks like the graph below. The flat<br />

parts of the curve at the top and bottom are typical of the settling<br />

time a normal controller requires to satisfy a “go to set-point”<br />

command. The normal controller does not move on to the next<br />

set-point until the controlled temperature has been within a set<br />

range of the current set-point for a specific amount of time. This<br />

process is appropriate for normal go-to-temperature commands,<br />

but wastes a lot of time in repetitive cycling where an instantaneous<br />

excursion to the upper and lower temperatures is all that is<br />

required.<br />

If you need to run a fast cycling program between two (or more)<br />

temperatures, but you do not need precise settling at each temperature,<br />

Touch ‘n Go can substantially speed the process. The<br />

Temperature ˚C<br />

120.0<br />

100.0<br />

80.0<br />

60.0<br />

40.0<br />

20.0<br />

<strong>Sigma</strong> <strong>Systems</strong> "Touch 'n Go"<br />

Using TP294 Thermal Platform<br />

& Adjustable Settling Band Feature<br />

Touch 'n Go Cycle - 3.3 minutes<br />

Normal cycle - 8.8 minutes<br />

120.0<br />

<strong>Sigma</strong> <strong>Systems</strong> Normal Temperature Cycling<br />

Using TP294 Thermal Platform<br />

Normal cycle - 8.8 minutes<br />

0.0<br />

–20.0<br />

0.8<br />

2.6<br />

4.4<br />

6.2<br />

8.0<br />

Time - minutes<br />

9.8<br />

11.6<br />

13.4<br />

15.2<br />

Using Standard Control<br />

Using Adjustable Settling Band Feature<br />

17.0<br />

18.8<br />

20.6<br />

22.4<br />

24.2<br />

26.0<br />

27.8<br />

29.6<br />

Temperature ˚C<br />

100.0<br />

80.0<br />

60.0<br />

40.0<br />

20.0<br />

following graph shows the Touch ‘n Go advantage in action.<br />

The chart shows the dramatic difference Touch ‘n Go made in a real<br />

<strong>Sigma</strong> customer test. The red line shows how the controller immediately<br />

changed direction to the next set-point as soon as it reached<br />

the current set-point. The conditioning cycle was reduced from 8.8<br />

to 3.3 minutes.<br />

0.0<br />

–20.0<br />

0.8<br />

2.6<br />

4.4<br />

6.2<br />

8.0<br />

Time - minutes<br />

9.8<br />

11.6<br />

13.4<br />

15.2<br />

17.0<br />

18.8<br />

Using Standard Control<br />

20.6<br />

22.4<br />

24.2<br />

26.0<br />

27.8<br />

29.6<br />

For 50 cycles of this test, Touch ‘n Go would save 4 hours and 35<br />

minutes.<br />

For 3000 cycles, a test running 24 hours a day, 7 days a week...<br />

---“Normal” test time = 2 weeks, 4 days, and 8 hours<br />

---Touch ‘n Go test time = 0 weeks, 6 days, and 21 hours<br />

www.<strong>Sigma</strong><strong>Systems</strong>.com

T-Drive tm - Thermal Overdrive feature built-in to every <strong>C4</strong> controller<br />

T-Drive is thermal overdrive that slashes test times<br />

T-Drive is a <strong>C4</strong> controller feature that can provide dramatic<br />

improvements in thermal test and conditioning times for high<br />

mass and thermally latent DUTs. While the concept of thermal<br />

overdriving is as old as food baking, until now controlling thermal<br />

overdrive to provide useful benefits has proven largely illusive.<br />

T-Drive makes thermal overdriving easy, very safe, and efficient.<br />

While T-Drive will be of significant use to a variety of users,<br />

those with relatively high performance temperature chambers<br />

who are testing/conditioning high mass or thermally latent loads<br />

will see the most substantial benefits. The long soak times often<br />

associated with such tests/conditioning can often be cut to half, or<br />

even less.<br />

The chart below shows a typical DUT temperature curve from<br />

a normal “ramp and soak” profile that would be used to bring a<br />

load to the set-point test temperature. A long soak at the set-point<br />

is typically required to allow the DUT to become substantially<br />

thermally homogeneous at the set-point temperature.<br />

T-Drive is stress controlled ramping at maximum speed<br />

There are times when you want the fastest possible test, but need to<br />

use slower ramps to control the thermal stress applied to your DUT.<br />

Rather than guessing at a ramp rate that will protect your DUT, you<br />

can let T-Drive maximize the ramp speed while preventing excessive<br />

thermal stress (shock).<br />

Simply set the allowable stress your DUT can tolerate, and T-Drive<br />

will apply the maximum acceleration to your test without exceeding<br />

the stress limits you set. You can even set different allowable stress<br />

levels at different temperatures and let T-Drive proportion the allowable<br />

stress at the points in between. With T-Drive you can have<br />

thermal overdriving and stress management at the same time.<br />

Test data show that, with T-Drive, total test time can be substantially<br />

reduced while thermal stress is actually managed better than with<br />

traditional methods of time based ramping. The combined result is<br />

substantially improved test times and reduced thermal stress.<br />

The chart below shows an example of thermal overdrive and thermal<br />

stress management simultaneously applied by T-Drive to an accelerated<br />

test profile.<br />

Temperature °C<br />

Temperature °C<br />

T-Drive can accelerate the test by providing a carefully controlled<br />

thermal overdrive condition that will speed heat transfer and<br />

reduce test time while still maintaining a controlled approach to<br />

the set-point. T-Drive allows you to set finite temperature limits<br />

so that T-Drive will use all the thermal overdrive your chamber<br />

or platform can deliver without ever over heating or over cooling<br />

your DUT. Below is a chart showing the same DUT temperature<br />

curve with T-Drive thermal overdrive in action with DUT temperature<br />

limits clearly respected.<br />

Want the latest firmware and features for<br />

your <strong>C4</strong> controller for free?<br />

The current version of <strong>C4</strong> firmware, with all advanced features<br />

included, is always available for download from our web site for<br />

free. The download includes a PC based loader program for loading<br />

the firmware into the <strong>C4</strong>.<br />

Temperature °C<br />

If you would simply like us to send you the new firmware, just call<br />

us with a controller serial number and your credit card information<br />

and we will send you a new EEPROM with the latest firmware, prepaid<br />

by FedEx or equivalent, for $50 (in USA - higher elsewhere).<br />

Want <strong>C4</strong> features for your older<br />

<strong>Sigma</strong> CC-3 controller?<br />

For less than ¹⁄₃ of the price of a new <strong>C4</strong>, you can convert your older<br />

<strong>Sigma</strong> CC-3 controller to a CC-3.5 with all the <strong>C4</strong> firmware features.<br />

Ask your <strong>Sigma</strong> representative or sales engineer for a CC-3.5<br />

Conversion brochure, or get it from www.<strong>Sigma</strong><strong>Systems</strong>.com. Only<br />

<strong>Sigma</strong> continues to protect your investment even decades after you<br />

buy.<br />

www.<strong>Sigma</strong><strong>Systems</strong>.com