Model YST Steam-Turbine Drive Centrifugal Liquid ... - Usair-eng.com

Model YST Steam-Turbine Drive Centrifugal Liquid ... - Usair-eng.com

Model YST Steam-Turbine Drive Centrifugal Liquid ... - Usair-eng.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

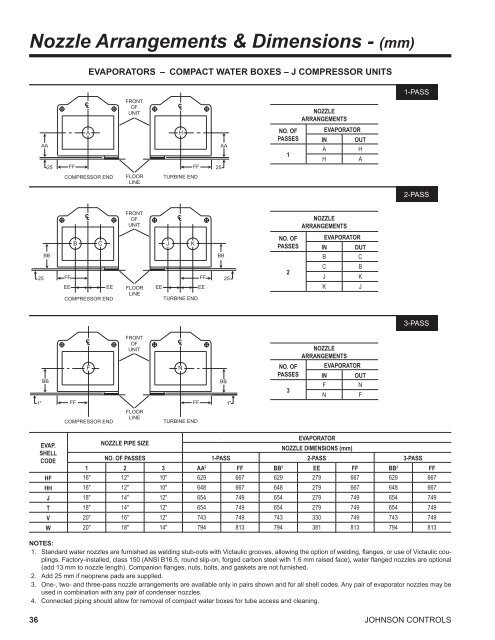

Nozzle Arrangements & Dimensions - (mm)<br />

EVAPORATORS – COMPACT WATER BOXES – J COMPRESSOR UNITS<br />

1-PASS<br />

FRONT<br />

OF<br />

UNIT<br />

NOZZLE<br />

ARRANGEMENTS<br />

AA<br />

25<br />

FF<br />

A<br />

H<br />

FF<br />

25<br />

AA<br />

NO. OF<br />

PASSES<br />

1<br />

EVAPORATOR<br />

IN OUT<br />

A<br />

H<br />

H<br />

A<br />

COMPRESSOR END<br />

FLOOR<br />

LINE<br />

TURBINE END<br />

2-PASS<br />

FRONT<br />

OF<br />

UNIT<br />

NOZZLE<br />

ARRANGEMENTS<br />

25<br />

BB<br />

FF<br />

B<br />

C J K<br />

EE EE FLOOR EE EE<br />

LINE<br />

COMPRESSOR END<br />

TURBINE END<br />

FF<br />

BB<br />

25<br />

NO. OF<br />

PASSES<br />

2<br />

EVAPORATOR<br />

IN OUT<br />

B<br />

C<br />

C<br />

B<br />

J<br />

K<br />

K<br />

J<br />

3-PASS<br />

BB<br />

F<br />

COMPRESSOR END<br />

FRONT<br />

OF<br />

UNIT<br />

1" FF<br />

FF<br />

1"<br />

FLOOR<br />

LINE<br />

N<br />

TURBINE END<br />

BB<br />

NOZZLE<br />

ARRANGEMENTS<br />

NO. OF EVAPORATOR<br />

PASSES IN OUT<br />

F<br />

N<br />

3<br />

N<br />

F<br />

EVAPORATOR<br />

EVAP.<br />

NOZZLE PIPE SIZE<br />

NOZZLE DIMENSIONS (mm)<br />

SHELL<br />

CODE<br />

NO. OF PASSES 1-PASS 2-PASS 3-PASS<br />

1 2 3 AA 2 FF BB 2 EE FF BB 2 FF<br />

HF 16" 12" 10" 629 667 629 279 667 629 667<br />

HH 16" 12" 10" 648 667 648 279 667 648 667<br />

J 18" 14" 12" 654 749 654 279 749 654 749<br />

T 18" 14" 12" 654 749 654 279 749 654 749<br />

V 20" 16" 12" 743 749 743 330 749 743 749<br />

W 20" 18" 14" 794 813 794 381 813 794 813<br />

NOTES:<br />

1. Standard water nozzles are furnished as welding stub-outs with Victaulic grooves, allowing the option of welding, flanges, or use of Victaulic couplings.<br />

Factory-installed, class 150 (ANSI B16.5, round slip-on, forged carbon steel with 1.6 mm raised face), water flanged nozzles are optional<br />

(add 13 mm to nozzle l<strong>eng</strong>th). Companion flanges, nuts, bolts, and gaskets are not furnished.<br />

2. Add 25 mm if neoprene pads are supplied.<br />

3. One-, two- and three-pass nozzle arrangements are available only in pairs shown and for all shell codes. Any pair of evaporator nozzles may be<br />

used in <strong>com</strong>bination with any pair of condenser nozzles.<br />

4. Connected piping should allow for removal of <strong>com</strong>pact water boxes for tube access and cleaning.<br />

36 JOHNSON CONTROLS