Vektor-CD Performance Catalog - Greenheck

Vektor-CD Performance Catalog - Greenheck

Vektor-CD Performance Catalog - Greenheck

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Vektor</strong>-<strong>CD</strong> Selection: Fan Curves<br />

Every laboratory or fume exhaust application has a unique set of criteria that must be evaluated in order to<br />

determine the most effective exhaust system. The selection of a <strong>Vektor</strong>-<strong>CD</strong> requires the total lab exhaust volume<br />

(effluent) per fan along with a determination of the external static pressure. Other considerations when making<br />

fan selections include: sound requirements, electrical limitations, size constraints, and the effective plume rise.<br />

1) Determine the laboratory exhaust requirements<br />

• Determine the total lab exhaust volume<br />

(effluent) per fan.<br />

• Determine the external static pressure entering<br />

the fan system.<br />

Bypass Air Plenums - Estimated Pressure Drop<br />

• Variable volume lab exhaust systems and<br />

systems adding dilution air require a bypass air<br />

plenum and damper.<br />

• <strong>Greenheck</strong>’s computer aided product selection<br />

software (CAPS), automatically adds external<br />

system static pressure to account for the<br />

bypass air plenum and isolation damper.<br />

2) Select the appropriate <strong>Vektor</strong>-<strong>CD</strong><br />

A Select <strong>Vektor</strong>-<strong>CD</strong> fans with a minimum<br />

nozzle velocity of 3,000 feet per minute<br />

(ANSI Z9.5 and ASHRAE lab design<br />

guidelines), which is represented by the<br />

green vertical line in Figure 1.<br />

• All <strong>Vektor</strong>-<strong>CD</strong> curves indicate the<br />

minimum cfm necessary to meet this<br />

minimum velocity.<br />

3) Determine fan rpm<br />

• Locate the fan operating point (the intersection<br />

of the required airflow and static pressure) on<br />

the performance curve in Figure 1.<br />

In this example, the operating point is<br />

B<br />

17,000 cfm at 4 in. wg.<br />

The belt drive fan rpm can be estimated by<br />

comparing the operating point to any of the<br />

solid fan rpm curves and in this example, the<br />

operating point falls on the red 1734 rpm curve.<br />

Direct drive fan selections must use the 50 or<br />

C<br />

60 cycle rpm curves (yellow or blue curves).<br />

• Determine the brake horsepower by comparing<br />

the operating point to the dashed brake<br />

horsepower curves.<br />

In this example, the brake horsepower is above<br />

20, but slightly less than 30 hp. A minimum of a<br />

30 hp motor is recommended for this selection.<br />

4) LV, MV and HV Nozzles<br />

D Each fan size is available with Low Velocity<br />

(LV), Medium Velocity (MV), or High<br />

Velocity (HV) nozzles.<br />

• Multiple nozzles (VNT) allow for the optimization<br />

of brake horsepower, plume rise and<br />

acoustic performance.<br />

Note: For most applications, the LV or MV nozzles are<br />

recommended in order to limit the operating brake<br />

horsepower. HV nozzles are available for applications<br />

that require the highest plume rise.<br />

16<br />

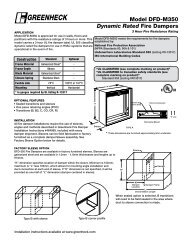

VEKTOR<strong>CD</strong>-30HV<br />

Figure 1: <strong>Vektor</strong>-<strong>CD</strong> Size 30 High Velocity<br />

A<br />

60% WOV<br />

50 Cycle RPM<br />

60 Cycle RPM<br />

C<br />

35<br />

14<br />

70% WOV<br />

Static Pressure (Pa x 100)<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Static Pressure (in. wg)<br />

RPM<br />

HP<br />

WOV<br />

Density 0.075<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

720<br />

870<br />

950<br />

MAX RESISTANCE CURVE<br />

2 hp<br />

1170<br />

5 hp<br />

1450<br />

7½ hp<br />

10 hp<br />

1734<br />

1900<br />

15 hp<br />

2050<br />

25 hp<br />

20 hp<br />

0<br />

0 4 8 12 16 20 24 28 32<br />

Volume (cfm x 1000)<br />

80% WOV<br />

90% WOV<br />

0 10 20 30 40 50<br />

Volume (m 3 /hr x 1000)<br />

2182<br />

30 hp<br />

40 hp<br />

50 hp<br />

60 hp<br />

B<br />

100% Wheel Width<br />

Windband<br />

Outlet Area<br />

Class II Fan<br />

Max rpm<br />

Class III Fan<br />

Max rpm<br />

<strong>Performance</strong><br />

Data<br />

= 8.3 ft 2 Nozzle Velocity<br />

{ft/min}<br />

= 1734<br />

= 2182<br />

Effective Plume @ 10 mph Crosswind<br />

Height {ft}<br />

(3 * Windband Outlet Volume * 0.392)<br />

880<br />

+ 11.50<br />

% WOV<br />

3000 fpm: Inlet<br />

Airflow Rate<br />

D<br />

LV MV HV<br />

Fan cfm Fan cfm Fan cfm<br />

4.35 ft 2 3.48 ft 2 2.61 ft 2<br />

cfm x 100<br />

rpm x 14.3<br />

cfm x 100<br />

rpm x 13.6<br />

cfm x 100<br />

rpm x 12.2<br />

13050 cfm 10440 cfm 7830 cfm<br />

10