Weishaupt dual fuel burners Sizes 30 to 70 ... - Pamber Energy

Weishaupt dual fuel burners Sizes 30 to 70 ... - Pamber Energy

Weishaupt dual fuel burners Sizes 30 to 70 ... - Pamber Energy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

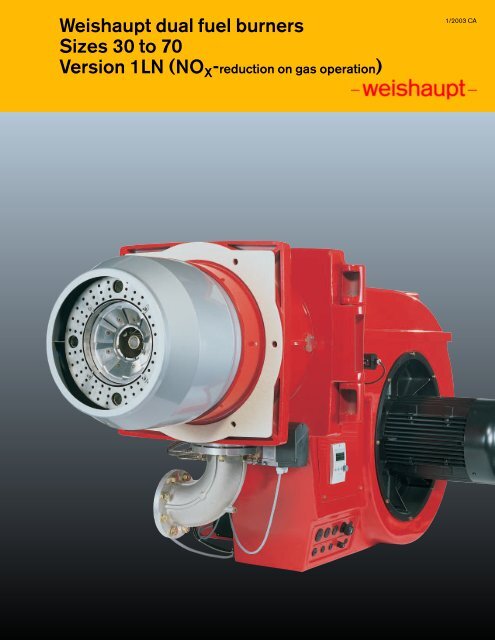

<strong>Weishaupt</strong> <strong>dual</strong> <strong>fuel</strong> <strong>burners</strong><br />

<strong>Sizes</strong> <strong>30</strong> <strong>to</strong> <strong>70</strong><br />

Version 1LN (NO X -reduction on gas operation)<br />

1/2003 CA

Description<br />

<strong>Weishaupt</strong> <strong>burners</strong> of sizes <strong>30</strong> <strong>to</strong> <strong>70</strong> were specially designed and developed for<br />

industrial applications. The Monoblock-Burners are characterized with multiple<br />

excellent features such as:<br />

• Big firing range and wide area of applications<br />

• Stable air fan performance – excellent combustion characteristics<br />

• Burner casing can be swung opened<br />

• Easy <strong>to</strong> install, setup and maintenance<br />

• Air damper closed off during burner s<strong>to</strong>p<br />

• Oil pump and electric oil heater is standard for heavy oil <strong>burners</strong><br />

Typical gas side Low NO x flame pattern<br />

Control<br />

Control of air and <strong>fuel</strong> is performed according<br />

<strong>to</strong> the <strong>fuel</strong> type, burner size and<br />

requirement:<br />

• Two and three stage<br />

The oil part of the <strong>dual</strong> <strong>fuel</strong> burner<br />

has a nozzle head with two or three<br />

nozzles. The capacity regulation is<br />

achieved by opening or closing the oil<br />

solenoid valves 2 and 3 with corresponding<br />

changes in air amount.<br />

• Sliding two stage<br />

On sliding two stage regulation, the<br />

low fire and high fire points are assigned<br />

within the control range. The<br />

burner slides depending on heat re<br />

quirement between both operating<br />

points. There is no sudden increase or<br />

decrease of supplied <strong>fuel</strong> amount.<br />

• Modulating<br />

Modulating <strong>burners</strong> operate according<br />

<strong>to</strong> the heat requirement at any operating<br />

point within the control range.<br />

Reduced starting capacity<br />

The burner starts at ignition position via<br />

separated pilot line. This way only a<br />

small amount of gas flows in<strong>to</strong> the combustion<br />

chamber. After a certain delay<br />

time the burner operates in low fire.<br />

Controlled shutdown from low fire<br />

Controlled shutdown of the burner is<br />

performed only at low fire. Sudden pressure<br />

surge in the gas supply line can be<br />

avoided.<br />

Gas train<br />

As standard, <strong>Weishaupt</strong> gas and <strong>dual</strong><br />

<strong>fuel</strong> <strong>burners</strong> are always equipped with<br />

two main gas valves.<br />

Gas train can be built according <strong>to</strong> most<br />

applicable North American codes and<br />

standards.<br />

Digital combustion manager<br />

W-FM100 and W-FM200 combustion<br />

manager control all essential burner<br />

functions, e.g. <strong>fuel</strong> and air supply and<br />

moni<strong>to</strong>r the flame with digital precision.<br />

The target is optimization of operating<br />

conditions, maximization of economical<br />

aspect and minimizing the emissions.<br />

Thanks <strong>to</strong> the digital combustion technology,<br />

such optimization is available<br />

<strong>to</strong>day at reasonable cost. Expenses for<br />

installation and maintenance are even<br />

clearly lower than with conventional<br />

technologies. For example, a separate<br />

remote panel is no longer required for<br />

burner control. Furthermore, remote<br />

operation, remote diagnostic and remote<br />

moni<strong>to</strong>ring of the appliances are now<br />

realizable. This increases the safety and<br />

comfort for opera<strong>to</strong>r.<br />

Applications<br />

The <strong>burners</strong> can be used with heat<br />

exchanger such as heating boiler, steam<br />

boiler, air heater and for certain process<br />

applications. Due <strong>to</strong> the fact that the<br />

burner is capable of overcoming high<br />

combustion chamber pressure, they are<br />

most compatible with modern high performance<br />

boilers.<br />

Fuels<br />

Oil section<br />

Light oil (#2 oil), viscosity 6mm 2 /s at<br />

68F (20°C)<br />

Gas section<br />

Natural gas<br />

Propane (LPG)<br />

Installation location<br />

The <strong>burners</strong> are designed for indoor<br />

operation with temperature of 5F<br />

(–15°C) up <strong>to</strong> 100F (+40°C) and relative<br />

humidity of max. 80%<br />

Certification<br />

The <strong>burners</strong> are in compliance with most<br />

applicable European and North<br />

American standards<br />

Excellent service<br />

<strong>Weishaupt</strong> has a high density sales and<br />

service network all over the world. The<br />

cus<strong>to</strong>mer service is available every day<br />

around the clock. Optimum in house<br />

training conditions ensure high quality of<br />

service personnel.<br />

2

Variants<br />

Digital combustion manager<br />

(W-FM 100)<br />

Electronic ratio controller (RVW)<br />

with O 2 trim<br />

Mechanical linkage<br />

Digital combustion manager<br />

(W-FM 100)<br />

with modulating controller<br />

Electronic ratio controller (RVW)<br />

with speed control<br />

Digital combustion manager<br />

(W-FM 100)<br />

with modulating controller<br />

and speed control<br />

Digital combustion manager<br />

(W-FM 200)<br />

with modulating controller<br />

O2 trim and speed control<br />

Capacity regulation<br />

Electronic ratio controller (RVW)<br />

with O 2 trim and<br />

speed control<br />

Standard<br />

Special version<br />

Two stage (ZM)<br />

Oil side<br />

HF G<br />

Sliding two stage<br />

(ZM)<br />

GHF<br />

LF K<br />

LF K<br />

IP Z<br />

ON Ein<br />

Aus OFF<br />

ON Ein<br />

OFF Aus<br />

Three stage (TM)<br />

Oil side<br />

GHF<br />

Modulating (ZM)<br />

GHF<br />

ZW INT<br />

LF T<br />

ON Ein<br />

OFF Aus<br />

HF = High Fire<br />

INT = Intermediate<br />

load<br />

LF = Low Fire<br />

IP = Ignition Position<br />

KLF<br />

ZIP<br />

ON Ein<br />

OFF Aus<br />

Burner designation<br />

RGL 40/1 – B, Vers. ZM-1LN<br />

Size<br />

Fuel: Light Oil<br />

Fuel: Gas<br />

Regulating burner<br />

Index for mixing head<br />

Code for capacity range<br />

LowNO x<br />

ZM = Gas/Oil: Sliding two stage<br />

or modulating<br />

GL 40/1 – B, Vers. TM-1LN<br />

LowNO x<br />

ZM =Gas: Sliding two stage or<br />

modulating<br />

Oil: Two stage<br />

TM = Gas: Sliding two stage or<br />

modulating<br />

Oil: Three stage<br />

Index for mixing head<br />

Code for capacity range<br />

Size<br />

Fuel: Light Oil<br />

Fuel: Gas<br />

3

The advantages of<br />

digital combustion management<br />

Control and Display Unit<br />

Digital combustion management<br />

means optimum combustion figures,<br />

continuous repeatability of setting<br />

values and ease of use.<br />

<strong>Weishaupt</strong> <strong>burners</strong> are equipped with<br />

electronic ratio controller and digital<br />

combustion management <strong>to</strong> satisfy the<br />

requirements of modern combustion<br />

technology, which demand a precise and<br />

continuously reproducible supply of <strong>fuel</strong><br />

and combustion air. Only in this way<br />

optimal combustion figures can be<br />

ensured over extended periods of time.<br />

If required, the <strong>burners</strong> can also be<br />

equipped with O 2 trim* and variable<br />

speed control.<br />

Error free operation via AZL display<br />

and control unit<br />

Setting and control of the burner functions<br />

is achieved using a control and display<br />

unit, the AZL, which is equipped<br />

with an LCD display. The AZL is connected<br />

<strong>to</strong> the combustion manager via a<br />

safety bus system and can be positioned<br />

anywhere according <strong>to</strong> the user’s<br />

preferences within 325 ft. (100 m) distance<br />

from the burner.<br />

Flexible communication possibilities<br />

The integrated communication interface<br />

enables all necessary information and<br />

functions <strong>to</strong> be transmitted <strong>to</strong> a BMS<br />

system. If required, remote operation and<br />

remote diagnosis functions, which are<br />

accessible via modem, can be installed<br />

(e.g. oil/gas change-over, adjustment of<br />

setting values).<br />

Communication with external systems<br />

via BUS<br />

If data has <strong>to</strong> be exchanged between<br />

<strong>burners</strong> and other heating systems with<br />

PLC devices, the information can be<br />

accessible via eBUS or MODBUS<br />

communication system.<br />

Integration with building management<br />

For control and management functions,<br />

<strong>Weishaupt</strong> offers ProGraf NT - a<br />

software product that provides a real<br />

time solution <strong>to</strong> meet all requirements.<br />

The price advantage of the new<br />

technology<br />

With improved technology and ease of<br />

use, combustion plant is becoming even<br />

more economical than ever before.<br />

• No additional burner controls are<br />

required, since this function is already<br />

governed by the combustion manager.<br />

Fuses and burner mo<strong>to</strong>r starter are the<br />

only additional items required.<br />

• Less installation work means less<br />

errors: the <strong>burners</strong> are tested as a<br />

complete unit at the fac<strong>to</strong>ry.<br />

• If required, the W-FM 100 is available<br />

with an integrated modulating controller<br />

and variable speed module. No<br />

separate equipment is required. The<br />

modulating controller and variable<br />

speed module are included as standard<br />

with the W-FM 200.<br />

• Commissioning and service work<br />

takes less time. The initial presetting<br />

of the burner is carried out at the fac<strong>to</strong>ry.<br />

On site, only the site specific<br />

operating points have <strong>to</strong> be adjusted.<br />

• To facilitate O 2 trim, only an O 2 probe<br />

and O 2 module have <strong>to</strong> be installed<br />

and connected with the W-FM 200<br />

via the internal safety BUS.<br />

* In conjunction with W-FM 200 combustion<br />

manager<br />

4

O 2 probe*<br />

O 2 module*<br />

Gas butterfly<br />

Stepping<br />

mo<strong>to</strong>rs<br />

Oil regula<strong>to</strong>r<br />

Air damper<br />

Frequency<br />

converter<br />

Impulse sender<br />

CAN-Bus<br />

W-FM 200<br />

combustion manager<br />

CAN-Bus<br />

Control and<br />

Display Unit<br />

eBus/<br />

MODBUS<br />

BMS<br />

visualization<br />

ProGraf NT<br />

Example of O 2 trim and speed control with W-FM 200<br />

5

Proven quality in detail<br />

Increased safety via shut off<br />

assembly with solenoid<br />

valve<br />

The electromagnetically actuated safety<br />

shut off device isolates the oil supply and<br />

return on burner models RGL40 <strong>to</strong> <strong>70</strong><br />

when the burner shuts down. Oil shut off<br />

directly at the nozzle ensures a drip free<br />

burner shut down. (Burner model<br />

RGL<strong>30</strong> uses a system without nozzle<br />

shut off).<br />

Considerable noise<br />

reduction due <strong>to</strong> sound<br />

absorbing air inlet<br />

By utilizing sound absorbing materials on<br />

the fan suction side it has been possible<br />

<strong>to</strong> reduce operational noise considerably.<br />

Cut-away of a nozzle shut of assembly<br />

Cut-away of the fan housing<br />

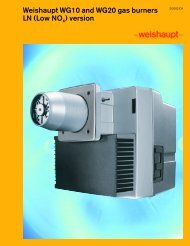

Emission figures for 1LN<br />

version<br />

Excellent emission results are achievable<br />

depending on the geometry of the<br />

combustion chamber, volume load and<br />

firing system (3 pass or reverse flame).<br />

[ppm]<br />

60<br />

50<br />

Example for Natural Gas operation<br />

NO x limit* with medium temperature < 2<strong>30</strong>F (110°C)<br />

When stating information relating <strong>to</strong><br />

guaranteed values, certain conditions for<br />

measurement and evaluation must be<br />

taken in<strong>to</strong> account, such as combustion<br />

chamber loading, test <strong>to</strong>lerances,<br />

temperature, pressure, humidity.<br />

The designation 1LN is used on the new<br />

<strong>Weishaupt</strong> Low NO x burner series.<br />

40<br />

<strong>30</strong><br />

20<br />

10<br />

0<br />

NO x<br />

CO<br />

* According <strong>to</strong> German TA-Luft regulation<br />

6

Burner with integrated Control and Display Unit<br />

7

Dual <strong>fuel</strong> burner selection<br />

Models GL and RGL<strong>30</strong>, 1LN version<br />

[“WC ] Burner model GL<strong>30</strong>/2-A, vers. ZM-1LN<br />

GL<strong>30</strong>/2-A, vers. TM-1LN<br />

RGL<strong>30</strong>/2-A, vers. ZM-1LN<br />

Combustion head<br />

G<strong>30</strong>/2-LN 190x35<br />

MBH Nat. Gas/Propane 1,000 – 6,400<br />

GPH Light oil #2 9 – 45<br />

5<br />

Combustion head “open”<br />

Combustion head “closed”<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Nat gas/LPG<br />

Light oil<br />

Light oil<br />

-1<br />

[MBH] 0 1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000<br />

[GPH] 0 10 20 <strong>30</strong> 40 50<br />

Burner model Version<br />

GL<strong>30</strong>/2-A ZM-1LN<br />

GL<strong>30</strong>/2-A TM-1LN<br />

The ratings given are based on <strong>fuel</strong> with low calorific value<br />

and an installation altitude of 0 ft. (0 m). Depending on the<br />

altitude of the installation, a reduction in capacity of<br />

approximately 1% for every 328 ft. (100 m) above sea level<br />

should be taken in<strong>to</strong> account.<br />

RGL<strong>30</strong>/2-A<br />

ZM-1LN<br />

The stated oil throughputs are based on a calorific value of<br />

140,000 BTU/Gal for light oil<br />

Voltages and frequencies:<br />

As standard, the <strong>burners</strong> are suitable for three phase alternating<br />

current available with various voltages from 208 - 600V, 60Hz.<br />

Different voltages and frequency are available on request.<br />

Standard burner mo<strong>to</strong>r:<br />

Isolation class F, IP 54 protection<br />

8

Dual <strong>fuel</strong> burner selection<br />

Models GL and RGL40, 1LN version<br />

[“WC ] Burner model GL40/1-B, vers. TM-1LN Combustion head “open”<br />

RGL40/1-B, vers. ZM-1LN<br />

Combustion head<br />

G<strong>30</strong>/2-LN 190x35K<br />

Combustion head “closed”<br />

MBH Natural gas 1,5<strong>30</strong> – 7,500<br />

Propane 1,5<strong>30</strong> – 7,500<br />

GPH Light oil #2 11 – 53<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

-1<br />

[MBH] 0 1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000 9,000 10,000<br />

Nat gas/LPG<br />

Light oil<br />

[GPH] 0 10 20 <strong>30</strong> 40 50 60<br />

[“WC ] Burner model GL40/2-A, vers. TM-1LN Combustion head “open”<br />

RGL40/2-A, vers. ZM-1LN<br />

Combustion head<br />

G40/2-LN 217x35K<br />

Combustion head “closed”<br />

MBH Natural gas 1,<strong>70</strong>0 – 10,500<br />

Propane 1,<strong>70</strong>0 – 10,500<br />

GPH Light oil #2 13 – 75<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

-1<br />

[MBH] 0 1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000 9,000 10,000 11,000 12,000<br />

Nat gas/LPG<br />

Light oil<br />

[GPH] 0 10 20 <strong>30</strong> 40 50 60 <strong>70</strong> 80<br />

Burner model Version<br />

GL40/1-B TM-1LN<br />

RGL40/1-B ZM-1LN<br />

The ratings given are based on <strong>fuel</strong> with low calorific value<br />

and an installation altitude of 0 ft. (0 m). Depending on the<br />

altitude of the installation, a reduction in capacity of<br />

approximately 1% for every 328 ft. (100 m) above sea level<br />

should be taken in<strong>to</strong> account.<br />

GL40/2-A<br />

RGL40/2-A<br />

TM-1LN<br />

ZM-1LN<br />

The stated oil throughputs are based on a calorific value of<br />

140,000 BTU/Gal for light oil<br />

Voltages and frequencies:<br />

As standard, the <strong>burners</strong> are suitable for three phase alternating<br />

current available with various voltages from 208 - 600V, 60Hz.<br />

Different voltages and frequency are available on request.<br />

Standard burner mo<strong>to</strong>r:<br />

Isolation class F, IP 54 protection<br />

9

Dual <strong>fuel</strong> burner selection<br />

Model RGL50, 1LN version<br />

[“WC] Burner model RGL50/1-B, vers. ZM-1LN<br />

Combustion head G40/2-LN 217x35K<br />

MBH Natural gas 1,<strong>70</strong>0 – 11,600<br />

Propane 1,<strong>70</strong>0 – 11,600<br />

GPH Light oil #2 20 – 82<br />

Combustion head “open”<br />

Combustion head “closed”<br />

[“WC ] Burner model RGL50/2-A, vers. ZM-1LN<br />

Combustion head G50/2-LN 260x40<br />

MBH Natural Gas 2,050 – 16,7<strong>30</strong><br />

Propane 2,7<strong>30</strong> – 16,7<strong>30</strong><br />

GPH Light oil #2 21 – 120<br />

Combustion head “open”<br />

Combustion head “closed”<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Nat gas/LPG<br />

Light oil<br />

-1<br />

[MBH] 0 2,000 4,000 6,000 8,000 10,000 12,000 14,000<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Nat gas<br />

Propane<br />

Light oil<br />

Light oil<br />

-1<br />

[MBH] 0 2,000 4,000 6,000 8,000 10,000 12,000 14,000 16,000 18,000<br />

[GPH] 0 10 20 <strong>30</strong> 40 50 60 <strong>70</strong> 80 90<br />

[GPH] 0 20 40 60 80 100 120<br />

Burner model Version<br />

RGL50/1-B ZM-1LN<br />

RGL50/2-A ZM-1LN<br />

The ratings given are based on <strong>fuel</strong> with low calorific value<br />

and an installation altitude of 0 ft. (0 m). Depending on the<br />

altitude of the installation, a reduction in capacity of<br />

approximately 1% for every 328 ft. (100 m) above sea level<br />

should be taken in<strong>to</strong> account.<br />

The stated oil throughputs are based on a calorific value of<br />

140,000 BTU/Gal for light oil<br />

Voltages and frequencies:<br />

As standard, the <strong>burners</strong> are suitable for three phase alternating<br />

current available with various voltages from 208 - 600V, 60Hz.<br />

Different voltages and frequency are available on request.<br />

Standard burner mo<strong>to</strong>r:<br />

Isolation class F, IP 54 protection<br />

10

Dual <strong>fuel</strong> burner selection<br />

Model RGL<strong>70</strong>, 1LN version<br />

[“WC] Burner model RGL<strong>70</strong>/1-B, vers. ZM-1LN<br />

Combustion head G<strong>70</strong>/1- 1LN 365x85<br />

MBH Natural gas 2,7<strong>30</strong> – 24,915<br />

Propane 3,410 – 24,915<br />

GPH Light oil #2 29 – 163<br />

Combustion head “open”<br />

Combustion head “closed”<br />

[“WC] Burner model RGL<strong>70</strong>/2-A, vers. ZM-1LN<br />

Combustion head G<strong>70</strong>/2-1LN 365x85<br />

MBH Natural Gas 3,400 – 34,1<strong>30</strong><br />

Propane 4,750 – 34,1<strong>30</strong><br />

GPH Light oil #2 46 – 244<br />

Combustion head “open”<br />

Combustion head “closed”<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

-1<br />

[MBH] 0 4,000 8,000 12,000 16,000 20,000 24,000<br />

Nat gas<br />

Propane<br />

Light oil<br />

Light oil<br />

Light oil<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

-1<br />

[MBH] 0 6,000 12,000 18,000 24,000 <strong>30</strong>,000 36,000<br />

Nat gas<br />

Propane<br />

Light oil<br />

Light oil<br />

[GPH] 0 20 40 60 80 100 120 140 160 180<br />

[GPH] 0 <strong>30</strong> 60 90 120 150 180 210 240 2<strong>70</strong><br />

Burner model Version<br />

RGL<strong>70</strong>/1-B ZM-1LN<br />

RGL<strong>70</strong>/2-A ZM-1LN<br />

The ratings given are based on <strong>fuel</strong> with low calorific value<br />

and an installation altitude of 0 ft. (0 m). Depending on the<br />

altitude of the installation, a reduction in capacity of<br />

approximately 1% for every 328 ft. (100 m) above sea level<br />

should be taken in<strong>to</strong> account.<br />

The stated oil throughputs are based on a calorific value of<br />

140,000 BTU/Gal for light oil<br />

Voltages and frequencies:<br />

As standard, the <strong>burners</strong> are suitable for three phase alternating<br />

current available with various voltages from 208 - 600V, 60Hz.<br />

Different voltages and frequency are available on request.<br />

Standard burner mo<strong>to</strong>r:<br />

Isolation class F, IP 54 protection<br />

11

Scope of delivery<br />

Description GL<strong>30</strong>-ZM GL<strong>30</strong>-TM RGL<strong>30</strong> GL40-TM RGL40 RGL<strong>70</strong><br />

RGL50<br />

Burner housing, hinged flange, housing cover,<br />

<strong>Weishaupt</strong> burner mo<strong>to</strong>r, air regulation housing,<br />

fan wheel, combustion head, ignition unit,<br />

ignition cable, ignition electrodes, nozzle assembly<br />

with oil nozzle(s), combustion manager with<br />

control unit, flame sensor, flange gasket, limit<br />

switch on hinged flange, fixing bolts ● ● ● ● ● ●<br />

W-FM 100 combustion manager ● ● ● ● ● ●<br />

Double main gas valves ● ● ● ● ● ●<br />

Gas butterfly valve ● ● ● ● ● ●<br />

Pilot gas valves ● ● ● ● ● ●<br />

Connection piece ● ● ● ● ● ●<br />

Air pressure switch ● ● ● ● ● ●<br />

Oil pressure switch in return ● ● ● ●<br />

Gas pressure switch ● ● ● ● ● ●<br />

Adjustable regulating sleeve<br />

in the mixing head ● ● ● ● ●<br />

Adjustable flame tube in<br />

the mixing head<br />

●<br />

Servomo<strong>to</strong>r for <strong>fuel</strong>/air compound<br />

regulation via W-FM 100<br />

Servomo<strong>to</strong>r for air damper ● ● ● ● ● ●<br />

Servomo<strong>to</strong>r for gas butterfly ● ● ● ● ● ●<br />

Servomo<strong>to</strong>r for oil regula<strong>to</strong>r ● ● ● ●<br />

Oil pump ● ● ● ● ● ●<br />

Oil hoses ● ● ● ● ● ●<br />

2 oil solenoid valves, 1 safety valve,<br />

two stage nozzle assembly without shut off<br />

●<br />

2 oil solenoid valves, 1 safety valve,<br />

two stage nozzle assembly with<br />

solenoid shut offg ● ●<br />

3 oil solenoid valves, 1 safety valve, three<br />

stage nozzle assembly without shut off ● ●<br />

2 solenoid valves in flow and return,<br />

nozzle assembly without shut off<br />

●<br />

Electromagnetic clutch ● ● ● ● ● ●<br />

12

Special equipment<br />

Description Size <strong>30</strong> Size 40 Size 50 Size <strong>70</strong><br />

Vertically firing burner version standard standard standard standard<br />

Air intake flange for connection of an air duct 280 003 47 280 001 68 280 000 92 280 000 13<br />

Combustion head extension by 6” (150 mm), model ../1-B – 290 008 96 290 009 00 290 010 78<br />

by 12” (<strong>30</strong>0 mm), model ../1-B – 290 008 97 290 009 01 290 010 79<br />

by 6” (150 mm), model ../2-A 290 008 90 290 008 98 290 009 39 290 009 59<br />

by 12” (<strong>30</strong>0 mm), model ../2-A 290 008 91 290 008 99 * *<br />

W-FM 100 with integrated modulating controller 290 010 60 290 010 60 290 010 60 290 010 60<br />

Burner controller<br />

Mechanical linkage with LFL flame safeguard in lieu of W-FM 100 -price reduction- 290 011 02 290 011 02 290 011 02 290 011 02<br />

Mechanical linkage with LGK flame safeguard in lieu of W-FM 100 -price reduction- 290 011 09 290 011 09 290 011 09 290 011 09<br />

Solenoid valve for air pressure switch test<br />

for continuous run fan or post purge 290 004 29 290 004 29 290 000 31 290 000 31<br />

* Contact <strong>Weishaupt</strong> corporation for more detailed information<br />

13

Technical Data<br />

<strong>Sizes</strong> <strong>30</strong> and 40<br />

Description GL<strong>30</strong>/2-A RGL<strong>30</strong>/2-A<br />

Burner mo<strong>to</strong>r Model D112/110-2 D112/110-2<br />

Mo<strong>to</strong>r rating HP (kW) 6.7 (5.0) 6.7 (5.0)<br />

Full Load Amps (FLA) at 460 V A 8.2 8.2<br />

Speed (60 Hz) rpm 3510 3510<br />

Fan wheel colour / ø red / 248 x 100 red / 248 x 100<br />

Combustion manager Model W-FM100 W-FM100<br />

Ignition unit Model W-ZG02/2 W-ZG02/2<br />

Servomo<strong>to</strong>r Model SQM 45 SQM 45<br />

Integral pump Model J6 TA3<br />

Oil solenoid valve 110V 1/4” 20 W Model 121 K 6220<br />

110V 1/8” 19 W Model 121 K 2423 –<br />

55V 1/4” (supply) 20 W Model – 121 K 6220<br />

55V 1/8” (return) 20 W Model – 121 K 2423<br />

55V 3/8” (supply) 20 W Model – –<br />

55V 3/8” (return) 20 W Model – –<br />

Oil pressure switch 1 - 10 bar (return - 5 bar) Model – DSA 46 F001<br />

Oil hoses DN / Length 13/40” (1000mm) 20/40” (1000mm)<br />

Burner weight lbs (kg) 297 (135) 319 (145)<br />

Technical data GL40/1-B RGL40/1-B<br />

GL40/2-A<br />

RGL40/2-A<br />

Burner mo<strong>to</strong>r Model D112/140-2 D112/140-2<br />

Mo<strong>to</strong>r rating HP (kW) 10.5 (7.8) 10.5 (7.8)<br />

Full Load Amps (FLA) at 460 V A 11.5 11.5<br />

Speed (60 Hz) rpm 3450 3450<br />

Fan wheel colour / ø red / 275 x 100 red / 275 x 100<br />

Combustion manager Model W-FM100 W-FM100<br />

Ignition unit Model W-ZG02/2 W-ZG02/2<br />

Servomo<strong>to</strong>r Model SQM 45 SQM 45<br />

Integral pump Model J6➀ TA3<br />

Oil solenoid valve 110V 1/8” 19 W Model 121 K 2423 –<br />

110V 1/4” (safety valve) 20 W Model 121 K 6220 –<br />

55V 3/8” (supply) 20 W Model – 321 H 2322<br />

55V 3/8” (return) 20 W Model – 121 G 2320<br />

Oil pressure switch 1 - 10 bar (return - 5 bar) Type – DSA 46 F001<br />

Oil hoses DN / Length 13/40” (1000mm) 20/40” (1000)<br />

Burner weight lbs (kg) 352 (160) 352 (160)<br />

➀<br />

Burners > 60 GPH (200 kg/h): oil pump J7 in lieu of J6 (refer <strong>to</strong> Special Equipment for additional cost)<br />

Burners > 72 GPH (250 kg/h): oil pump TA2 in lieu of J6 (refer <strong>to</strong> Special Equipment for additional cost)<br />

14

Technical Data<br />

<strong>Sizes</strong> 50 and <strong>70</strong><br />

Description RGL50/1-B RGL50/2-A<br />

Burner mo<strong>to</strong>r Model D132/1<strong>70</strong>-2a D132/1<strong>70</strong>-2<br />

Mo<strong>to</strong>r rating HP (kW) 14 (10.5) 20 (15)<br />

Full Load Amps (FLA) at 460 V A 17.2 23.2<br />

Speed (60 Hz) rpm 3500 3500<br />

Fan wheel colour / ø red / 3<strong>30</strong> x 100 red / 3<strong>30</strong> x 100<br />

Combustion manager Model W-FM100 W-FM100<br />

Ignition unit Model W-ZG02/2 W-ZG02/2<br />

Servomo<strong>to</strong>r Model SQM 45 SQM 45<br />

Integral pump Model TA4C T2C<br />

Oil solenoid valve 55V 3/8” (supply) 20 W Model 321 H 2322 321 H 2322<br />

55V 3/8” (return) 20 W Model 121 G 2320 121 G 2320<br />

Oil pressure switch 1 - 10 bar (return - 5 bar) Model DSA 46 F001 DSA 46 F001<br />

Oil hoses DN / Length 25/51” (1<strong>30</strong>0mm) 25/51” (1<strong>30</strong>0mm)<br />

Burner weight lbs (kg) 517 (235) 528 (240)<br />

Technical data RGL<strong>70</strong>/1-B RGL<strong>70</strong>/2-A<br />

Burner mo<strong>to</strong>r Model D160/215-2B D160/215-2<br />

Mo<strong>to</strong>r rating HP (kW) 25 (19) 29.5 (22)<br />

Full Load Amps (FLA) at 460 V A 32.2 36<br />

Speed (60 Hz) rpm 3400 3500<br />

Fan wheel colour / ø green / 5<strong>30</strong> x 120 green / 5<strong>30</strong> x 120<br />

Combustion manager Model W-FM100 W-FM 100<br />

Ignition unit Model W-ZG02/2 W-ZG02/2<br />

Servomo<strong>to</strong>r Model SQM 45 SQM 45<br />

Integral pump Model T2C (<strong>to</strong> 175 GPH)) T2C (<strong>to</strong> 175 GPH)<br />

(<strong>to</strong> 600 kg/h)<br />

(<strong>to</strong> 600 kg/h)<br />

T3C (from 175 GPH) T3C (from 175 GPH)<br />

(from 600 kg/h) (from 600 kg/h)<br />

Oil solenoid valve 55V 1/2” (supply) 20W Model 321 H 2522 321 H 2522<br />

55V 1/2” (return) 20W Model 121 G 2520 121 G 2520<br />

Oil pressure switch 2 – 40 bar (flow - 18 bar) Model – –<br />

1 – 10 bar (return - 5 bar) Model DSA 46 F 001 DSA 46 F 001<br />

Oil hoses DN/Length 25/51” (1<strong>30</strong>0mm) 25/51” (1<strong>30</strong>0mm)<br />

Burner weight lbs (kg) 957 (435) 957 (435)<br />

15

Burner <strong>fuel</strong> systems<br />

Type GL<strong>30</strong>Z (oil side)<br />

10 13<br />

13a 16a<br />

Types GL<strong>30</strong>T / GL40T (oil side)<br />

10 13<br />

13a 16a<br />

Type RGL<strong>30</strong> (oil side)<br />

10 12<br />

12 16a<br />

55V<br />

55V<br />

55V<br />

P<br />

M<br />

55V<br />

13a<br />

13a 13a<br />

12a 14<br />

15 12a<br />

Types RGL40 <strong>to</strong> RGL<strong>70</strong> (oil side)<br />

10 11 12<br />

16<br />

Types <strong>30</strong> <strong>to</strong> <strong>70</strong> (gas side)<br />

with double main gas valves and pilot line<br />

6<br />

7<br />

4b<br />

4b<br />

9<br />

55V<br />

55V<br />

P<br />

M<br />

P<br />

P<br />

12a 14<br />

15<br />

2<br />

3 4<br />

1<br />

5<br />

8<br />

Legend<br />

1 Isolating cock<br />

2 Main gas pressure regula<strong>to</strong>r<br />

3 Low gas pressure switch<br />

4 Double main gas valves<br />

4b Pilot gas valves<br />

5 High gas pressure switch<br />

6 Isolating valve for pilot gas train<br />

7 Pilot gas pressure regula<strong>to</strong>r<br />

8 Gas butterfly valve<br />

9 Burner<br />

10 Oil pump<br />

11 Oil filter<br />

12 Normally closed oil solenoid valve (55 V,<br />

electrically connected in series with 12a)<br />

12a Normally closed oil solenoid valve (55 V,<br />

electrically connected in series with 12,<br />

fitted against the direction of flow)<br />

12b Normally open bypass oil solenoid valve<br />

13 Normally closed oil solenoid valve<br />

13a Normally closed oil solenoid valve for<br />

stages 1, 2 and 3<br />

14 Oil pressure switch in return<br />

15 Oil regula<strong>to</strong>r<br />

16 Nozzle assembly with shut off device<br />

(solenoid valve)<br />

16a Nozzle assembly without shut off device<br />

17 Oil preheater<br />

18 Pt100 temperature sensor (<strong>to</strong> moni<strong>to</strong>r<br />

minimum oil temperature)<br />

16

Dimensions<br />

<strong>Sizes</strong> <strong>30</strong> and 40<br />

Size<br />

<strong>30</strong>/2-A<br />

40/1-B<br />

40/2-A<br />

<strong>30</strong>/2-A<br />

40/1-B<br />

40/2-A<br />

Dimensions in inches (mm)<br />

l1 l2 l3 l5 l6 l7 l8 l9 l10 l11 b1 b2 b3 b4 b5 b6<br />

42.6 9.6 10.7 0.3 13.9 11.8 2.3 9.4 4.8 1.3 35.2 14.6 8.2 27.6 16.5 13.0<br />

(1083) (245) (272) (8) (354) (<strong>30</strong>0) (58) (238) (123) (32) (895) (371) (208) (<strong>70</strong>0) (418) (3<strong>30</strong>)<br />

44.4 10.6 10.7 0.3 16.3 12.6 2.3 9.4 4.8 1.3 37.4 15.8 9.5 29.7 18.2 13.0<br />

(1128) (2<strong>70</strong>) (272) (8) (414) (320) (58) (238) (123) (32) (950) (401) (242) (755) (462) (3<strong>30</strong>)<br />

45.2 10.6 13.1 0.3 16.3 13.4 2.6 10.2 5.2 1.7 37.4 15.8 9.5 29.7 18.2 14.6<br />

(1148) (2<strong>70</strong>) (332) (8) (414) (340) (67) (258) (133) (42) (950) (401) (242) (755) (462) (3<strong>70</strong>)<br />

h1 h2 h3 h4 h6 d1 d2 d4 d5 d6 d7 d8➀ r1➂ r2<br />

22.5 8.1 16.0 8.1 13.0 11.0 9.8 8.6 M12 14.2 11.2 DN50 38.2 35.0<br />

(572) (207) (407) (207) (3<strong>30</strong>) (280) (250) (218) (M12) (360) (285) (DN50) (9<strong>70</strong>) (890)<br />

23.9 8.3 16.6 8.1 13.0 11.0 9.8 8.6 M12 14.2 11.2 DN50 41.3 38.2<br />

(607) (211) (422) (207) (3<strong>30</strong>) (280) (250) (218) (M12) (360) (285) (DN50) (1050) (9<strong>70</strong>)<br />

23.9 8.3 16.6 8.9 14.6 12.6 11.4 8.6 M12 15.7 12.8 DN65 41.3 38.2<br />

(607) (211) (422) (227) (3<strong>70</strong>) (320) (290) (218) (M12) (400) (325) (DN65) (1050) (9<strong>70</strong>)<br />

➀ Flange connection<br />

➁ Pilot line connection either side<br />

➂ With electromagnetic clutch<br />

All measurements are approximate. <strong>Weishaupt</strong> reserves the right <strong>to</strong> make alterations in light of future developments.<br />

17

Dimensions<br />

<strong>Sizes</strong> 50<br />

Size<br />

50/1-B<br />

50/2-A<br />

50/1-B<br />

50/2-A<br />

Dimensions in inches (mm)<br />

l1 l2 l3 l5 l6 l7 l8 l9 l10 l11 b1 b2 b3 b4 b5 b6<br />

47.0 12.4 13.1 0.3 16.6 14.3 2.6 10.2 5.2 1.7 41.7 17.3 10.9 32.3 21.7 14.6<br />

(1195) (315) (332) (8) (422) (363) (67) (258) (133) (42) (1060) (440) (277) (820) (550) (3<strong>70</strong>)<br />

49.0 12.4 17.6 0.3 16.6 16.3 2.8 12.1 6.2 2.6 43.3 18.3 10.9 33.9 21.7 16.9<br />

(1245) (315) (447) (8) (422) (413) (72) (<strong>30</strong>8) (158) (65) (1100) (465) (277) (860) (550) (4<strong>30</strong>)<br />

h1 h2 h3 h4 h6 d1 d2 d4 d5 d6 d7 d8➀ r1➂ r2<br />

28.7 10.4 20.2 8.9 14.6 12.6 11.4 10.2 M12 15.7 12.8 DN65 46.5 39.4<br />

(7<strong>30</strong>) (263) (513) (227) (3<strong>70</strong>) (319) (290) (258) (M12) (400) (325) (DN65) (1180) (1000)<br />

28.7 10.4 20.2 10.1 16.9 15.0 13.8 10.2 M16 18.9 15.4 DN80 46.5 40.4<br />

(7<strong>30</strong>) (263) (513) (257) (4<strong>30</strong>) (382) (350) (258) (M16) (480) (390) (DN80) (1180) (1025)<br />

➀ Flange connection<br />

➁ Pilot line connection either side<br />

➂ With electromagnetic clutch<br />

All measurements are approximate. <strong>Weishaupt</strong> reserves the right <strong>to</strong> make alterations in light of future developments.<br />

18

Dimensions<br />

<strong>Sizes</strong> <strong>70</strong><br />

d 5<br />

d 7<br />

d 6<br />

Size<br />

<strong>70</strong>/1-B<br />

<strong>70</strong>/2-A<br />

<strong>70</strong>/1-B<br />

<strong>70</strong>/2-A<br />

Dimensions in inches (mm)<br />

l1 l2 l3 l5 l6 l7 l8 l9 l10 l11 b1 b2 b3 b4 b5 b6<br />

64.9 19.0 16.5 0.3 24.2 20.1 3.9 13.7 7.0 3.4 55.5 23.7 13.4 44.3 29.9 20.5<br />

(1648) (483) (419) (8) (614) (510) (100) (348) (178) (87) (1410) (602) (340) (1125) (760) (520)<br />

65.7 19.0 17.6 0.3 24.2 20.9 3.9 14.5 7.4 3.4 55.5 23.7 13.4 44.3 29.9 23.6<br />

(1668) (483) (447) (8) (614) (5<strong>30</strong>) (100) (368) (188) (87) (1410) (602) (340) (1125) (760) (600)<br />

h1 h2 h3 h4 h5 d1 d2 d3 d4 d5 d6 d7 d8➀ r1➂ r2<br />

42.3 16.5 <strong>30</strong>.5 11.9 20.5 17.0 16.0 – 12.2 M16 18.5 17.1 DN100 59.1 51.6<br />

(1075) (420) (775) (<strong>30</strong>2) (520) (432) (406) – (310) (M16) (4<strong>70</strong>) (435) (DN100) (1500) (1310)<br />

42.3 16.5 <strong>30</strong>.5 12.4 23.6 18.5 – 18.9 12.2 M16 21.7 19.7 DN100 59.1 51.6<br />

(1075) (420) (775) (315) (600) (4<strong>70</strong>) – (480) (310) (M16) (550) (500) (DN100) (1500) (1310)<br />

➀ Flange connection<br />

➁ Pilot line connection either side<br />

➂ With electromagnetic clutch<br />

All measurements are approximate. <strong>Weishaupt</strong> reserves the right <strong>to</strong> make alterations in light of future developments.<br />

19

Product and cus<strong>to</strong>mer service<br />

the complete <strong>Weishaupt</strong> range<br />

<strong>Weishaupt</strong> Corporation<br />

6280 Danville Road<br />

Mississauga, ON L5T 2H7<br />

Ph.: (905) 564 0946, Fax.: (905) 564 0949<br />

www.weishaupt-corp.com<br />

Print No. 83203816, August 2003<br />

Printed in Germany. All rights reserved.<br />

Regular maintenance reduces heating<br />

costs and environmental pollution. Only a<br />

properly adjusted burner can save<br />

energy and be environmentally friendly.<br />

Behind each <strong>Weishaupt</strong> burner stands<br />

the whole <strong>Weishaupt</strong> cus<strong>to</strong>mer service<br />

organization. The outstanding efforts<br />

made in maintenance and service justify<br />

the enormous trust placed in<br />

<strong>Weishaupt</strong>’s <strong>burners</strong>, for at <strong>Weishaupt</strong><br />

product and cus<strong>to</strong>mer service belong<br />

<strong>to</strong>gether.<br />

<strong>Weishaupt</strong> cus<strong>to</strong>mer service is there for<br />

you all year round. Whenever you need<br />

help, be it the supply of spare parts,<br />

technical advice or a site visit. We are<br />

there when you need us.