Springs and Spring Washers - Electronic Fasteners Inc

Springs and Spring Washers - Electronic Fasteners Inc

Springs and Spring Washers - Electronic Fasteners Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

EXTENSION SPRINGS<br />

EXTENSION SPRINGS<br />

Stock sizes in music wire <strong>and</strong> stainless steel<br />

Associated <strong>Spring</strong> Raymond SPEC extension springs have a wide application for<br />

experimental, development, prototype <strong>and</strong> maintenance work, <strong>and</strong> have been specified,<br />

designed <strong>and</strong> manufactured to high precision st<strong>and</strong>ards.<br />

All SPEC extension springs have uniform body diameter <strong>and</strong> are produced with full<br />

twist loops.<br />

They are wound with initial tension, therefore some force is required before the coils<br />

are initially separated.<br />

Materials<br />

Part numbers starting with E in the following pages:<br />

Music Wire: ASTM A228 or AMS 5112<br />

Stainless Steel: Type 302 per ASTM A313 or AMS 5688 spring temper<br />

(Chemical <strong>and</strong> Physical only)<br />

Part numbers starting with T in the following pages:<br />

Music Wire: DIN 17223 or JIS G4314 SWP-A/B or AMS 5112<br />

Stainless Steel: Type 301, 302 or 304 per DIN 17224 or JIS G4314 SUS 302/304<br />

or AMS 5688 spring temper (chemical <strong>and</strong> physical only)<br />

For specific T part number look up, please see page 87.<br />

Music wire will be furnished unless stainless steel is specified. When inquiring or<br />

ordering, please use letter "M" or Letter "S" as suffix to designate music wire or<br />

stainless steel, respectively.<br />

Music wire springs are not recommended for applications where the temperature<br />

exceeds 121 degrees C. (250 degrees F.). Stainless steel is not recommended above<br />

260 degrees C. (500 degrees F.).<br />

Stainless steel is slightly magnetic due to cold working during manufacturing.<br />

Stainless steel springs may have a slight residue of nickel on the surface of the wire.<br />

This is normal <strong>and</strong> will not effect the function of the part.<br />

Wire diameter is prior to forming.<br />

No charge for certificate of compliance when requested; certificate of chemical<br />

analysis available only for part numbers starting with E in the following pages (an<br />

additional charge applies).<br />

Coil Direction (helix)<br />

Right or left according to machine set-up at time of run. Coil count is for reference<br />

only.<br />

Free Length<br />

Free length is reference or approximate only.<br />

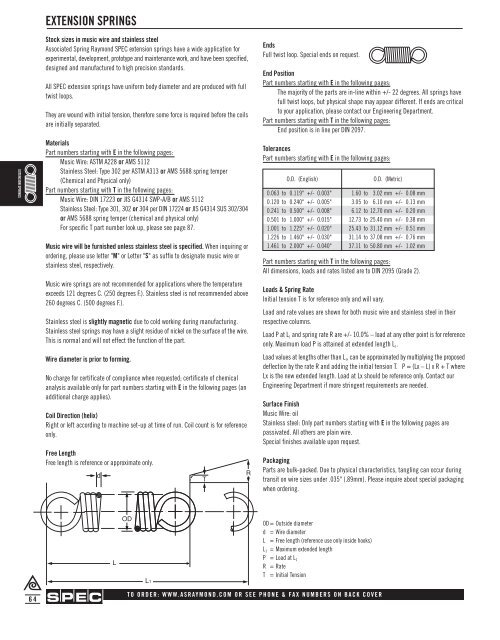

d<br />

T<br />

R<br />

Ends<br />

Full twist loop. Special ends on request.<br />

End Position<br />

Part numbers starting with E in the following pages:<br />

The majority of the parts are in-line within +/- 22 degrees. All springs have<br />

full twist loops, but physical shape may appear different. If ends are critical<br />

to your application, please contact our Engineering Department.<br />

Part numbers starting with T in the following pages:<br />

End position is in line per DIN 2097.<br />

Tolerances<br />

Part numbers starting with E in the following pages:<br />

O.D. (English)<br />

O.D. (Metric)<br />

0.063 to 0.119" +/- 0.003" 1.60 to 3.02 mm +/- 0.08 mm<br />

0.120 to 0.240" +/- 0.005" 3.05 to 6.10 mm +/- 0.13 mm<br />

0.241 to 0.500" +/- 0.008" 6.12 to 12.70 mm +/- 0.20 mm<br />

0.501 to 1.000" +/- 0.015" 12.73 to 25.40 mm +/- 0.38 mm<br />

1.001 to 1.225" +/- 0.020" 25.43 to 31.12 mm +/- 0.51 mm<br />

1.226 to 1.460" +/- 0.030" 31.14 to 37.08 mm +/- 0.76 mm<br />

1.461 to 2.000" +/- 0.040" 37.11 to 50.80 mm +/- 1.02 mm<br />

Part numbers starting with T in the following pages:<br />

All dimensions, loads <strong>and</strong> rates listed are to DIN 2095 (Grade 2).<br />

Loads & <strong>Spring</strong> Rate<br />

Initial tension T is for reference only <strong>and</strong> will vary.<br />

Load <strong>and</strong> rate values are shown for both music wire <strong>and</strong> stainless steel in their<br />

respective columns.<br />

Load P at L 1 <strong>and</strong> spring rate R are +/- 10.0% – load at any other point is for reference<br />

only. Maximum load P is attained at extended length L 1 .<br />

Load values at lengths other than L 1 , can be approximated by multiplying the proposed<br />

deflection by the rate R <strong>and</strong> adding the initial tension T. P = (Lx – L) x R + T where<br />

Lx is the new extended length. Load at Lx should be reference only. Contact our<br />

Engineering Department if more stringent requirements are needed.<br />

Surface Finish<br />

Music Wire: oil<br />

Stainless steel: Only part numbers starting with E in the following pages are<br />

passivated. All others are plain wire.<br />

Special finishes available upon request.<br />

Packaging<br />

Parts are bulk-packed. Due to physical characteristics, tangling can occur during<br />

transit on wire sizes under .035" (.89mm). Please inquire about special packaging<br />

when ordering.<br />

L<br />

OD<br />

L1<br />

OD = Outside diameter<br />

d = Wire diameter<br />

L = Free length (reference use only inside hooks)<br />

L 1 = Maximum extended length<br />

P = Load at L 1<br />

R = Rate<br />

T = Initial Tension<br />

64<br />

TO ORDER: WWW.ASRAYMOND.COM OR SEE PHONE & FAX NUMBERS ON BACK COVER