Biuletyn Instytutu Spawalnictwa No. 01/2012

Biuletyn Instytutu Spawalnictwa No. 01/2012

Biuletyn Instytutu Spawalnictwa No. 01/2012

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ination of its power and width (duration).<br />

Therefore, these radiation beam parameters<br />

cannot be shaped freely, as one cannot freely<br />

define the duration and emission frequency of<br />

a pulse for the assumed value of the average<br />

power of a radiation beam. The energy of a<br />

pulse cannot exceed the maximum value defined<br />

for a given resonator.<br />

The average power of laser radiation in pulsed<br />

mode is defined as the product of the average<br />

power of the radiation of one pulse P i<br />

,<br />

the duration of this pulse t i<br />

and the number<br />

of pulses per a second expressed through the<br />

frequency of emission f. For a given average<br />

power there is a number of combinations of<br />

the selection of pulse energy and pulse repetition<br />

frequency.<br />

P śr<br />

= P i<br />

× t i<br />

× f = E i<br />

× F (1)<br />

The frequency of a pulse emission is a parameter<br />

closely related to the period of their occurrence<br />

expressed in the following relation:<br />

A weld produced by a laser beam emitted in<br />

pulsed mode is composed of a number of overlapping<br />

spot welds. The degree of overlapping<br />

of individual pulses expressed in percentage,<br />

i.e. the so-called overlap, represents the degree<br />

at which the area of a material molten by<br />

a single pulse overlaps a similar area produced<br />

by the previous pulse. By means of a specific<br />

overlap one can control the amount of heat<br />

supplied to a material being welded, as well as<br />

influence the homogeneity of the structure of<br />

a weld.<br />

The overlap is defined by the rate of the<br />

welding process appropriately selected in relation<br />

to the frequency of pulses. In turn, the<br />

frequency of pulses depends on the pre-defined<br />

power of a pulse and its duration. If an<br />

area molten by a single pulse of a laser beam<br />

takes an elliptic shape (as a result of the pro-<br />

1 ⎡ 1 ⎤<br />

T =<br />

f ⎢<br />

s =<br />

⎣ Hz ⎥ ⎦<br />

(2)<br />

The average energy of laser radiation for<br />

the pulsed operation mode is defined as the<br />

product of the average radiation power and radiation<br />

beam action time.<br />

E śr<br />

=P śr<br />

× t [J] (3)<br />

In the case of single pulse spot welding, an<br />

important parameter is the density of pulse power.<br />

GP<br />

i<br />

Pi<br />

Ei<br />

= =<br />

A t × A<br />

i<br />

⎡ J<br />

⎢<br />

⎣s<br />

⋅ m<br />

(4)<br />

where A represents the focusing area of a<br />

radiation beam.<br />

In the case of a pre-defined average power<br />

of a radiation beam P śr<br />

, the density of the power<br />

supplied to the area unit, i.e. the average<br />

2<br />

⎤<br />

⎥<br />

⎦<br />

area power density, is determined by means of<br />

the following quotient:<br />

GP<br />

śr<br />

=<br />

P<br />

śr<br />

A<br />

⎡ W<br />

⎢<br />

⎣m<br />

2<br />

⎤<br />

⎥<br />

⎦<br />

(5)<br />

The quotient of the area power density GP śr<br />

and radiation beam action time determines the<br />

average area power density:<br />

GEśr = GPśr<br />

× t<br />

⎡ J<br />

⎢<br />

⎣m<br />

(6)<br />

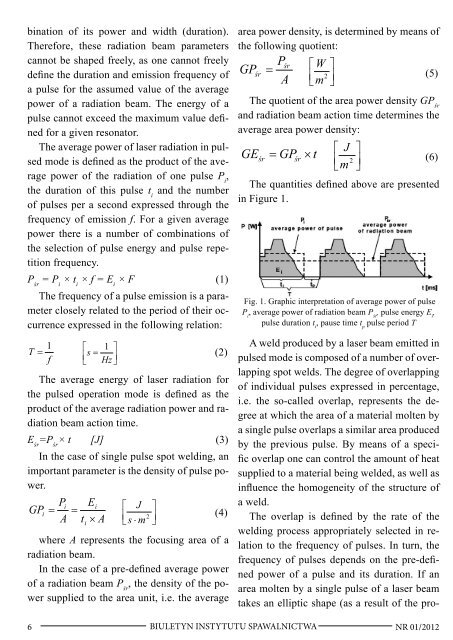

The quantities defined above are presented<br />

in Figure 1.<br />

Fig. 1. Graphic interpretation of average power of pulse<br />

P i<br />

, average power of radiation beam P śr<br />

, pulse energy E i<br />

,<br />

pulse duration t i<br />

, pause time t p<br />

pulse period T<br />

2<br />

⎤<br />

⎥<br />

⎦<br />

6 BIULETYN INSTYTUTU SPAWALNICTWA<br />

NR <strong>01</strong>/2<strong>01</strong>2