Technical Manual on Utilization of Sympodial Bamboos - ITTO

Technical Manual on Utilization of Sympodial Bamboos - ITTO

Technical Manual on Utilization of Sympodial Bamboos - ITTO

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 3<br />

Traditi<strong>on</strong>al Processing and Its Products I I<br />

eutuliloides is needed due to its cool, smooth, s<strong>of</strong>t with glittering and translucent<br />

color, fine grain and superb heat dissipati<strong>on</strong>.<br />

3. 2 Machine-processed Bamboo Products for Daily Use<br />

Machine-processed bamboo products for daily use mainly include mats, chopsticks,<br />

toothpicks etc. As a result <strong>of</strong> the development <strong>of</strong> bamboo processing sector, the<br />

mechanizati<strong>on</strong> producti<strong>on</strong> <strong>of</strong> these products has replaced handwork.<br />

Bamboo mats, <strong>on</strong>e <strong>of</strong> the main bamboo products in China, are manufactured in<br />

all the provinces <strong>of</strong> southern China. According to their comp<strong>on</strong>ents, machine-processed<br />

bamboo mats can be classified into two sorts: machine-processed bamboo<br />

strip mats and bamboo domino mats.<br />

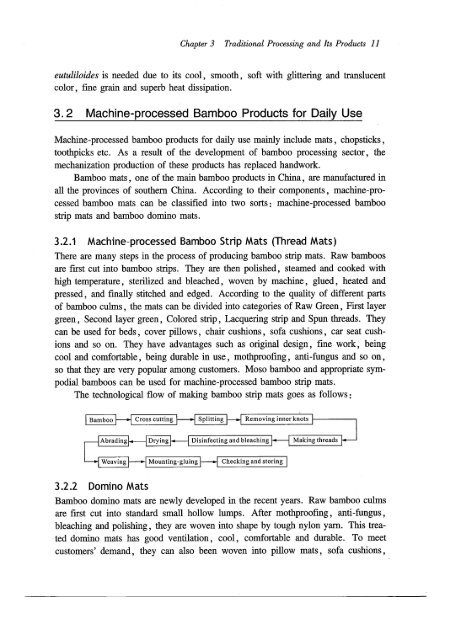

3.2.1 Machine-processed Bamboo Strip Mats (Thread Mats)<br />

There are many steps in the process <strong>of</strong> producing bamboo strip mats. Raw bamboos<br />

are first cut into bamboo strips. They are then polished, steamed and cooked with<br />

high temperature, sterilized and bleached, woven by machine, glued, heated and<br />

pressed, and fmally stitched and edged. According to the quality <strong>of</strong> different parts<br />

<strong>of</strong> bamboo culms, the mats can be divided into categories <strong>of</strong> Raw Green, First layer<br />

green, Sec<strong>on</strong>d layer green, Colored strip, Lacquering strip and Spun threads. They<br />

can be used for beds, cover pillows, chair cushi<strong>on</strong>s, s<strong>of</strong>a cushi<strong>on</strong>s, car seat cushi<strong>on</strong>s<br />

and so <strong>on</strong>. They have advantages such as original design, fine work, being<br />

cool and comfortable, being durable in use, mothpro<strong>of</strong>ing, anti-fungus and so <strong>on</strong>,<br />

so that they are very popular am<strong>on</strong>g customers. Moso bamboo and appropriate sympodial<br />

bamboos can be used for machine-processed bamboo strip mats.<br />

The technological flow <strong>of</strong> making bamboo strip mats goes as follows:<br />

Removing inner knots<br />

Disinfecting and bleaching<br />

I Mounting-gluing H Checking and storing I<br />

Making threads<br />

3.2.2 Domino Mats<br />

Bamboo domino mats are newly developed in the recent years. Raw bamboo culms<br />

are first cut into standard small hollow lumps. After mothpro<strong>of</strong>ing, anti-fungus,<br />

bleaching and polishing, they are woven into shape by tough nyl<strong>on</strong> yarn. This treated<br />

domino mats has good ventilati<strong>on</strong>, cool, comfortable and durable. To meet<br />

customers' demand, they can also been woven into pillow mats, s<strong>of</strong>a cushi<strong>on</strong>s,

![[ID]Peta Jalan Menuju Pengelolaan Ramin - ITTO](https://img.yumpu.com/49466232/1/184x260/idpeta-jalan-menuju-pengelolaan-ramin-itto.jpg?quality=85)

![[ID]Review and Measures to Improve Its Implementation - ITTO](https://img.yumpu.com/49270549/1/184x260/idreview-and-measures-to-improve-its-implementation-itto.jpg?quality=85)