Welcome to Practical Components - Standard ICs

Welcome to Practical Components - Standard ICs

Welcome to Practical Components - Standard ICs

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

θ<br />

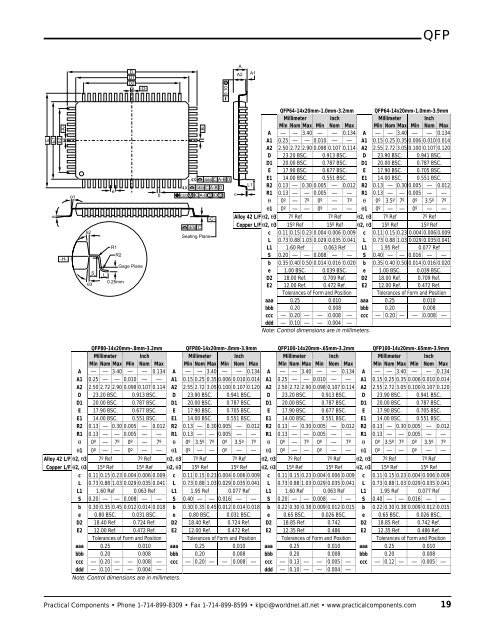

QFP<br />

D<br />

D1<br />

D2<br />

-D-<br />

s<br />

0.10<br />

A<br />

A2<br />

A1<br />

E<br />

E1<br />

E2<br />

θ1<br />

θ2<br />

θ3<br />

S<br />

e<br />

R1<br />

R2<br />

Gage Plane<br />

L<br />

0.25mm<br />

b<br />

-A-<br />

-B-<br />

-H-<br />

4X aaa C A-B D<br />

4X bbb C A-B D<br />

ccc M C A-B S D S<br />

-Cddd<br />

C<br />

Seating Plane<br />

QFP64-14x20mm-1.0mm-3.2mm QFP64-14x20mm-1.0mm-3.9mm<br />

Millimeter Inch Millimeter Inch<br />

Min Nom Max Min Nom Max Min Nom Max Min Nom Max<br />

A — — 3.40 — — 0.134 A — — 3.40 — — 0.134<br />

A1 0.25 — — 0.010 — — A1 0.15 0.25 0.35 0.006 0.010 0.014<br />

A2 2.50 2.72 2.90 0.098 0.107 0.114 A2 2.55 2.72 3.05 0.100 0.107 0.120<br />

D 23.20 BSC. 0.913 BSC. D 23.90 BSC. 0.941 BSC.<br />

D1 20.00 BSC. 0.787 BSC. D1 20.00 BSC. 0.787 BSC.<br />

E 17.90 BSC. 0.677 BSC. E 17.90 BSC. 0.705 BSC.<br />

E1 14.00 BSC. 0.551 BSC. E1 14.00 BSC. 0.551 BSC.<br />

L1 R2 0.13 — 0.30 0.005 — 0.012 R2 0.13 — 0.30 0.005 — 0.012<br />

c<br />

R1 0.13 — — 0.005 — — R1 0.13 — — 0.005 — —<br />

θ 0º — 7º 0º — 7º θ 0º 3.5º 7º 0º 3.5º 7º<br />

θ1 0º — — 0º — — θ1 0º — — 0º — —<br />

Alloy 42 L/F θ2, θ3 7º Ref 7º Ref θ2, θ3 7º Ref 7º Ref<br />

Copper L/F θ2, θ3 15º Ref 15º Ref θ2, θ3 15º Ref 15º Ref<br />

c 0.11 0.15 0.23 0.004 0.006 0.009 c 0.11 0.15 0.23 0.004 0.006 0.009<br />

L 0.73 0.88 1.03 0.029 0.035 0.041 L 0.73 0.88 1.03 0.029 0.035 0.041<br />

L1 1.60 Ref 0.063 Ref L1 1.95 Ref 0.077 Ref<br />

S 0.20 — — 0.008 — — S 0.40 — — 0.016 — —<br />

b 0.35 0.40 0.50 0.014 0.016 0.020 b 0.35 0.40 0.50 0.014 0.016 0.020<br />

e 1.00 BSC. 0.039 BSC. e 1.00 BSC. 0.039 BSC.<br />

D2 18.00 Ref. 0.709 Ref. D2 18.00 Ref. 0.709 Ref.<br />

E2 12.00 Ref. 0.472 Ref. E2 12.00 Ref. 0.472 Ref.<br />

Tolerances of Form and Position Tolerances of Form and Position<br />

aaa 0.25 0.010 aaa 0.25 0.010<br />

bbb 0.20 0.008 bbb 0.20 0.008<br />

ccc — 0.20 — — 0.008 — ccc — 0.20 — — 0.008 —<br />

ddd — 0.10 — — 0.004 —<br />

Note: Control dimensions are in millimeters.<br />

QFP80-14x20mm-.8mm-3.2mm QFP80-14x20mm-.8mm-3.9mm QFP100-14x20mm-.65mm-3.2mm QFP100-14x20mm-.65mm-3.9mm<br />

Millimeter Inch Millimeter Inch Millimeter Inch Millimeter Inch<br />

Min Nom Max Min Nom Max Min Nom Max Min Nom Max Min Nom Max Min Nom Max Min Nom Max Min Nom Max<br />

A — — 3.40 — — 0.134 A — — 3.40 — — 0.134 A — — 3.40 — — 0.134 A — — 3.40 — — 0.134<br />

A1 0.25 — — 0.010 — — A1 0.15 0.25 0.35 0.006 0.010 0.014 A1 0.25 — — 0.010 — — A1 0.15 0.25 0.35 0.006 0.010 0.014<br />

A2 2.50 2.72 2.90 0.098 0.107 0.114 A2 2.55 2.72 3.05 0.100 0.107 0.120 A2 2.50 2.72 2.90 0.098 0.107 0.114 A2 2.55 2.72 3.05 0.100 0.107 0.120<br />

D 23.20 BSC. 0.913 BSC. D 23.90 BSC. 0.941 BSC. D 23.20 BSC. 0.913 BSC. D 23.90 BSC. 0.941 BSC.<br />

D1 20.00 BSC. 0.787 BSC. D1 20.00 BSC. 0.787 BSC. D1 20.00 BSC. 0.787 BSC. D1 20.00 BSC. 0.787 BSC.<br />

E 17.90 BSC. 0.677 BSC. E 17.90 BSC. 0.705 BSC. E 17.90 BSC. 0.677 BSC. E 17.90 BSC. 0.705 BSC.<br />

E1 14.00 BSC. 0.551 BSC. E1 14.00 BSC. 0.551 BSC. E1 14.00 BSC. 0.551 BSC. E1 14.00 BSC. 0.551 BSC.<br />

R2 0.13 — 0.30 0.005 — 0.012 R2 0.13 — 0.30 0.005 — 0.012 R2 0.13 — 0.30 0.005 — 0.012 R2 0.13 — 0.30 0.005 — 0.012<br />

R1 0.13 — — 0.005 — — R1 0.13 — — 0.005 — — R1 0.13 — — 0.005 — — R1 0.13 — — 0.005 — —<br />

θ 0º — 7º 0º — 7º θ 0º 3.5º 7º 0º 3.5º 7º θ 0º — 7º 0º — 7º θ 0º 3.5º 7º 0º 3.5º 7º<br />

θ1 0º — — 0º — — θ1 0º — — 0º — — θ1 0º — — 0º — — θ1 0º — — 0º — —<br />

Alloy 42 L/F θ2, θ3 7º Ref 7º Ref θ2, θ3 7º Ref 7º Ref θ2, θ3 7º Ref 7º Ref θ2, θ3 7º Ref 7º Ref<br />

Copper L/F θ2, θ3 15º Ref 15º Ref θ2, θ3 15º Ref 15º Ref θ2, θ3 15º Ref 15º Ref θ2, θ3 15º Ref 15º Ref<br />

c 0.11 0.15 0.23 0.004 0.006 0.009 c 0.11 0.15 0.23 0.004 0.006 0.009 c 0.11 0.15 0.23 0.004 0.006 0.009 c 0.11 0.15 0.23 0.004 0.006 0.009<br />

L 0.73 0.88 1.03 0.029 0.035 0.041 L 0.73 0.88 1.03 0.029 0.035 0.041 L 0.73 0.88 1.03 0.029 0.035 0.041 L 0.73 0.88 1.03 0.029 0.035 0.041<br />

L1 1.60 Ref 0.063 Ref L1 1.95 Ref 0.077 Ref L1 1.60 Ref 0.063 Ref L1 1.95 Ref 0.077 Ref<br />

S 0.20 — — 0.008 — — S 0.40 — — 0.016 — — S 0.20 — — 0.008 — — S 0.40 — — 0.016 — —<br />

b 0.30 0.35 0.45 0.012 0.014 0.018 b 0.30 0.35 0.45 0.012 0.014 0.018 b 0.22 0.30 0.38 0.009 0.012 0.015 b 0.22 0.30 0.38 0.009 0.012 0.015<br />

e 0.80 BSC. 0.031 BSC. e 0.80 BSC. 0.031 BSC. e 0.65 BSC. 0.026 BSC. e 0.65 BSC. 0.026 BSC.<br />

D2 18.40 Ref. 0.724 Ref. D2 18.40 Ref. 0.724 Ref. D2 18.85 Ref. 0.742 D2 18.85 Ref. 0.742 Ref.<br />

E2 12.00 Ref. 0.472 Ref. E2 12.00 Ref. 0.472 Ref. E2 12.35 Ref. 0.486 E2 12.35 Ref. 0.486 Ref.<br />

Tolerances of Form and Position Tolerances of Form and Position Tolerances of Form and Position Tolerances of Form and Position<br />

aaa 0.25 0.010 aaa 0.25 0.010 aaa 0.25 0.010 aaa 0.25 0.010<br />

bbb 0.20 0.008 bbb 0.20 0.008 bbb 0.20 0.008 bbb 0.20 0.008<br />

ccc — 0.20 — — 0.008 — ccc — 0.20 — — 0.008 — ccc — 0.13 — — 0.005 — ccc — 0.12 — — 0.005 —<br />

ddd — 0.10 — — 0.004 — ddd — 0.10 — — 0.004 —<br />

Note: Control dimensions are in millimeters.<br />

<strong>Practical</strong> <strong>Components</strong> • Phone 1-714-899-8309 • Fax 1-714-899-8599 • klpci@worldnet.att.net • www.practicalcomponents.com 19