DECEMBER 2011 - Electrical Business Magazine

DECEMBER 2011 - Electrical Business Magazine

DECEMBER 2011 - Electrical Business Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The n- and p-types of silicon are created by<br />

adding minute amounts of other substances—a<br />

process called doping. This produces radical<br />

changes in the electrical properties of the<br />

overall structure. Specifically, an n-type<br />

semiconductor is created by doping the<br />

silicon with a material that has five valence<br />

electrons, commonly phosphorus. A p-type<br />

semiconductor is created by doping the<br />

silicon with a material that has three valence<br />

electrons, commonly boron.<br />

As mentioned, to extract usable energy from<br />

the PV cell, it is necessary to install electrodes<br />

on the cell and connect them to an external<br />

load. The back-side contact, away from<br />

the incoming light, is relatively simple. An<br />

aluminum or molybdenum plate is attached.<br />

But the front side, facing the light source, is<br />

more of a challenge because a solid plate, like<br />

on the back side, would block the light. So the<br />

front-side electrode, by necessity, consists of<br />

some sort of grid that spreads across the face<br />

of the cell and collects the electrical current.<br />

This grid must spread to all parts of the cell<br />

since the silicon has a relatively high resistance<br />

and current would not readily flow through it.<br />

If the ‘fingers’ that form the grid are too<br />

large, they will block the incoming light,<br />

resulting in a loss of energy. If they are too<br />

small, there will be an ampacity problem—also<br />

resulting in energy loss. Various solutions<br />

are possible, such as making these front-side<br />

electrodes deep, rather than wide, and choosing<br />

a low-resistance metal. Top surface grids can be<br />

made by depositing metal vapours through a<br />

mask, or using a screen-printing procedure.<br />

An efficient front-side grid shades only<br />

about 3% to 5% of the cell’s surface, and<br />

minimizes resistance loss.<br />

Another approach has been to employ a<br />

transparent conducting oxide layer. Tin oxide<br />

has been used successfully.<br />

The output of a solar cell is direct current<br />

(DC), and this is fine for many stand-alone<br />

scenarios such as keeping batteries charged to<br />

power electronic equipment in remote locations<br />

where a utility connection is not available.<br />

Isolated homesteads use such a DC output to<br />

good effect for lighting and light-duty usage.<br />

On a somewhat larger scale, individual<br />

homes and businesses with substantial solar<br />

arrays may co-generate along with a utility.<br />

During a sunny day when electrical demand<br />

is low, excess energy is fed back into the grid,<br />

and this fact is reflected in the metering. For<br />

this interaction to take place, the DC has to<br />

be processed by a synchronous inverter. Direct<br />

current is changed to alternating current,<br />

utility frequency is matched, and the waveform<br />

is synchronized, or locked in phase, so that<br />

a useful power transfer can occur. It is also<br />

necessary to provide transfer switch capability<br />

so that in an outage utility workers will not be<br />

exposed to danger.<br />

Constant innovation<br />

Solar technology is characterized by constant<br />

innovation. One of the big stories is the (price)<br />

war between thin-film and crystal factions.<br />

Thin-film solar cells first appeared as small<br />

strips used to power hand-held calculators, and<br />

stand in opposition to wafer and bulk silicon.<br />

A thin-film solar cell is created by vapour<br />

deposition. The silicon is deposited on metal,<br />

glass or plastic, then coated with transparent<br />

conducting oxide to provide a top-side<br />

electrode with good characteristics for the<br />

collection of electrical current. Thin-film solar<br />

panels are being successfully used as integrated<br />

building materials, such as photovoltaic<br />

roofing shingles and building siding. We can<br />

visualize a time when commercial buildings<br />

and residences will come equipped with the<br />

capability to harvest their own energy supply<br />

from the solar radiation that strikes their<br />

outside finish surfaces. (The capability exists<br />

at present, but economic barriers still exist<br />

before this potential can become a reality.)<br />

Thin-film has been less efficient than silicon<br />

crystal cells but, since it is generally cheaper<br />

to manufacture, it has made significant inroads<br />

prior to 2010. Then, without warning, the<br />

price of crystal silicon went into free fall. As a<br />

result, the market share of thin film declined<br />

by 30% that year.<br />

(Some players remain undaunted. First Solar,<br />

the largest manufacturer of thin-film solar<br />

panels, offers turn-key power plants. In Canada<br />

and the United States, First Solar provides<br />

utility customers and independent power<br />

producers with complete solar PV system<br />

solutions, including project development,<br />

financing, engineering, procurement and<br />

construction, as well as operations and<br />

maintenance for the life of the project.)<br />

Market possibilities<br />

It has been suggested that solar photovoltaic<br />

power generation may not be appropriate to<br />

Canada’s more northern regions, where there<br />

are colder temperatures and less direct sunlight.<br />

Also, the presence of abundant hydropower<br />

has been seen as an economic obstacle to the<br />

development of a solar infrastructure.<br />

These observations are not altogether valid,<br />

for several reasons. In the first place, colder<br />

ambient temperatures actually equate to higher<br />

electrical output on the part of a solar cell. The<br />

available power is a function of the temperature<br />

differential between the two sides of the p-n<br />

junction. As a matter of fact, electrical codes<br />

typically require correction factors for ambient<br />

temperatures below 25ºC. In areas under<br />

National <strong>Electrical</strong> Code (NEC) jurisdiction,<br />

the open-circuit voltage must be multiplied<br />

by a factor of 1.25; for example, when the<br />

temperature drops below -36ºC.<br />

Secondly, direct sunlight is not absolutely<br />

required for PV generation of electrical power.<br />

Moreover, solar power is highly compatible<br />

with hydro since it contributes diversity to<br />

system capability. In a time of drought, when<br />

hydro production diminishes, solar output<br />

will increase dramatically, making a far better<br />

situation for the grid.<br />

It is a fact that solar development in Canada<br />

has been extensive. For a period of time<br />

in 2010, Canada had the largest solar PV<br />

power station in the world: the 97 megawatt<br />

Sarnia PV power plant in Ontario. Far larger<br />

solar utility installations are now being built<br />

in many parts of the world. Government<br />

subsidies play a decisive role but, when they<br />

are removed as a result of shifting political<br />

and/or economic winds, it is possible for solar<br />

development to experience a period of decline.<br />

CanSIA (Canadian Solar Industries<br />

Association) is a national trade association that<br />

represents about 650 solar energy companies<br />

throughout Canada. The organization<br />

predicts that, by 2025, solar energy will be<br />

widely deployed throughout Canada and that<br />

the solar industry will support over 35,000<br />

jobs and displace 15 to 31 million tons of<br />

greenhouse gas emissions per year.<br />

No one know for sure what the future may<br />

bring for Canada, the North American grid,<br />

or the world as a whole, to say nothing of<br />

outer space. However, a few generalizations<br />

are possible.<br />

Fossil fuels are not going to be around forever.<br />

Nuclear power will always be problematic,<br />

unless that highly elusive goal of cold fusion is<br />

achieved. Biomass and similar solutions may be<br />

helpful, but will never be a complete answer. We<br />

probably need to moderate our need for energy,<br />

but it is hard to conceive that we will return to a<br />

pre-industrial existence.<br />

It is likely, therefore, that wind and solar<br />

power will play increasingly significant roles.<br />

Both of these are abundant resources. The only<br />

impediment to full usage is economics, but that<br />

seems to diminish with the passage of time.<br />

As professionals in the electrical industry,<br />

it appears that the best course of action is to<br />

be prepared for the altered reality that wind<br />

and solar will bring to our field of operations.<br />

Already, building and electrical codes are<br />

taking increasing notice of these sources of<br />

energy, and the ways in which they need to<br />

be harnessed so that they are safe for those<br />

who work with them, as well as the end<br />

users. Increasing our knowledge of applicable<br />

mandates and of the underlying electronics<br />

is certainly an appropriate response to our<br />

changing reality.<br />

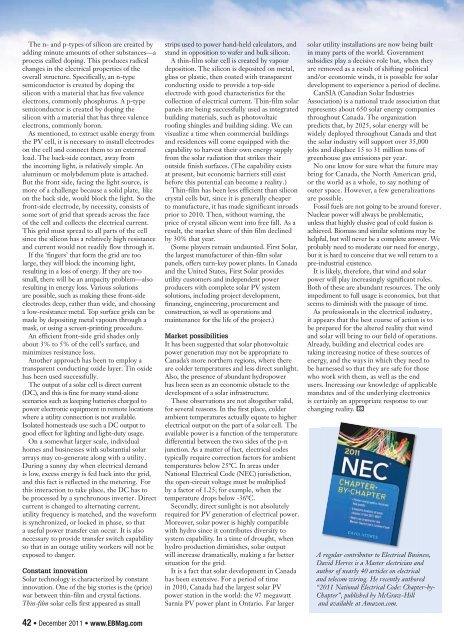

A regular contributor to <strong>Electrical</strong> <strong>Business</strong>,<br />

David Herres is a Master electrician and<br />

author of nearly 40 articles on electrical<br />

and telecom wiring. He recently authored<br />

“<strong>2011</strong> National <strong>Electrical</strong> Code: Chapter-by-<br />

Chapter”, published by McGraw-Hill<br />

and available at Amazon.com.<br />

42 • December <strong>2011</strong> • www.EBMag.com