CAST IRON INOCULATION - Elkem

CAST IRON INOCULATION - Elkem

CAST IRON INOCULATION - Elkem

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

7.2 Coarsening of Inclusions<br />

It has previously been discussed that<br />

graphite nucleation occurs from nonmetallic<br />

inclusions in the melt. A significant<br />

coarsening of these inclusions<br />

occurs within the time interval between<br />

inoculation and solidification of the cast<br />

iron. This coarsening of inclusions will<br />

result in a reduction in the inclusion<br />

number density, consequently reducing<br />

the graphite nucleation frequency.<br />

Hence, the fading of inoculation can<br />

be explained by this coarsening of the<br />

inclusion population with time. Due to<br />

the coarsening, the total number of<br />

possible nucleation sites for graphite<br />

during solidification is reduced.<br />

Figure 9 shows a plot of the number<br />

density of inclusions in cast iron as a<br />

function of holding time after inocu lation.<br />

7.3 Effects of Various Inclusions<br />

Inoculants lose their ability to reduce<br />

chill and nucleate graphite if the metal<br />

is held for extended periods before<br />

casting. However, inoculants have<br />

different fading characteristics. The<br />

barium-based Barinoc ® inoculant<br />

produces a high initial number of<br />

nucleation sites throughout the holding<br />

period, thus making it an excellent<br />

inoculant for ladle treatments.<br />

Foundrisil ® inoculant is an effective<br />

chill reducer for both low and high<br />

sulphur grey iron as well as ductile<br />

iron. Another effective inoculant that<br />

maintains the inoculation effect is the<br />

strontium-containing Superseed ®<br />

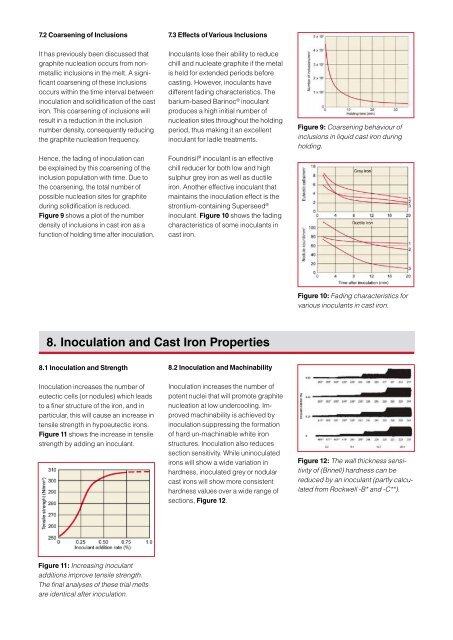

inoculant. Figure 10 shows the fading<br />

characteristics of some inoculants in<br />

cast iron.<br />

Figure 9: Coarsening behaviour of<br />

inclusions in liquid cast iron during<br />

holding.<br />

Figure 10: Fading characteristics for<br />

various inoculants in cast iron.<br />

8. Inoculation and Cast Iron Properties<br />

8.1 Inoculation and Strength<br />

Inoculation increases the number of<br />

eutectic cells (or nodules) which leads<br />

to a finer structure of the iron, and in<br />

particular, this will cause an increase in<br />

tensile strength in hypoeutectic irons.<br />

Figure 11 shows the increase in tensile<br />

strength by adding an inoculant.<br />

8.2 Inoculation and Machinability<br />

Inoculation increases the number of<br />

potent nuclei that will promote graphite<br />

nucleation at low undercooling. Improved<br />

machinability is achieved by<br />

inoculation suppressing the formation<br />

of hard un-machinable white iron<br />

structures. Inoculation also reduces<br />

section sensitivity. While uninoculated<br />

irons will show a wide variation in<br />

hardness, inoculated grey or nodular<br />

cast irons will show more consistent<br />

hardness values over a wide range of<br />

sections, Figure 12.<br />

Figure 12: The wall thickness sensitivity<br />

of (Brinell) hardness can be<br />

reduced by an inoculant (partly calculated<br />

from Rockwell -B* and -C**).<br />

Figure 11: Increasing inoculant<br />

additions improve tensile strength.<br />

The final analyses of these trial melts<br />

are identical after inoculation.