CAST IRON INOCULATION - Elkem

CAST IRON INOCULATION - Elkem

CAST IRON INOCULATION - Elkem

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

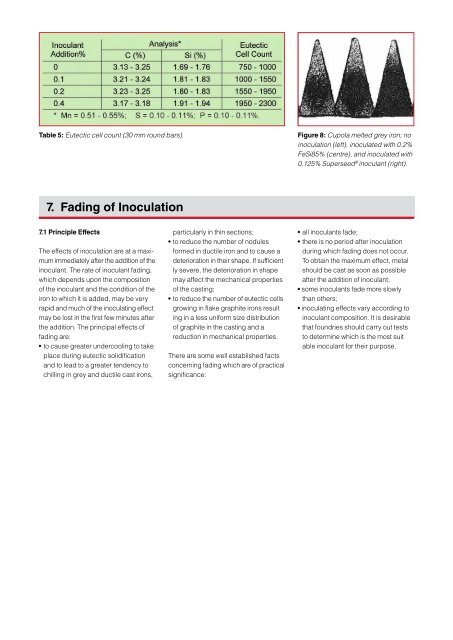

Table 5: Eutectic cell count (30 mm round bars).<br />

Figure 8: Cupola melted grey iron; no<br />

inoculation (left), inoculated with 0.2%<br />

FeSi85% (centre), and inoculated with<br />

0.125% Superseed ® inoculant (right).<br />

7. Fading of Inoculation<br />

7.1 Principle Effects<br />

The effects of inoculation are at a maximum<br />

immediately after the addition of the<br />

inoculant. The rate of inoculant fading,<br />

which depends upon the composition<br />

of the inoculant and the condition of the<br />

iron to which it is added, may be very<br />

rapid and much of the inoculating effect<br />

may be lost in the first few minutes after<br />

the addition. The principal effects of<br />

fading are:<br />

• to cause greater undercooling to take<br />

place during eutectic solidification<br />

and to lead to a greater tendency to<br />

chilling in grey and ductile cast irons,<br />

particularly in thin sections;<br />

• to reduce the number of nodules<br />

formed in ductile iron and to cause a<br />

deterioration in their shape. If suffic ient<br />

ly severe, the deterioration in shape<br />

may affect the mechanical properties<br />

of the casting;<br />

• to reduce the number of eutectic cells<br />

growing in flake graphite irons result<br />

ing in a less uniform size distribution<br />

of graphite in the casting and a<br />

reduction in mechanical properties.<br />

There are some well established facts<br />

concerning fading which are of practical<br />

significance:<br />

• all inoculants fade;<br />

• there is no period after inoculation<br />

during which fading does not occur.<br />

To obtain the maximum effect, metal<br />

should be cast as soon as possible<br />

after the addition of inoculant;<br />

• some inoculants fade more slowly<br />

than others;<br />

• inoculating effects vary according to<br />

inoculant composition. It is desirable<br />

that foundries should carry out tests<br />

to determine which is the most suit<br />

able inoculant for their purpose.