CAST IRON INOCULATION - Elkem

CAST IRON INOCULATION - Elkem

CAST IRON INOCULATION - Elkem

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6. Control of Inoculation<br />

Although nuclei cannot be observed<br />

directly at solidification temperatures,<br />

they have an effect on some properties<br />

which can be measured by:<br />

• recording cooling curves<br />

• measuring depth of chill in chill<br />

wedges<br />

• counting the number of eutectic cells<br />

• counting the number of graphite<br />

nodules<br />

6.1 Cooling Curves<br />

Cooling curves record the changes<br />

in temperature with time as a consequence<br />

of a change of energy within<br />

the system. A deviation from normal<br />

cooling indicates the occurrence of a<br />

source of heat such as the heat of<br />

crystallization released by a precipitating<br />

phase. The location of the inversion<br />

points on the generally S-shaped<br />

cooling curve in the region of eutectic<br />

crystallization indicates the tendency<br />

of the melt to solidify “grey” or “white”.<br />

A high level of nucleation promotes a<br />

higher arrest temperature which, by<br />

avoiding the white eutectic, will result<br />

in less risk of carbide formation.<br />

Conversely, when the inversion point is<br />

at a low level on the cooling curve, there<br />

will be a tendency for cementite to<br />

precipitate instead of graphite giving a<br />

“white” structure. An increased cooling<br />

rate, as found in thin sections, will increase<br />

the degree of undercooling that<br />

must be balanced by an increased<br />

number of active nuclei to avoid the<br />

formation of white iron. In the iron-carbon<br />

system there is only a 7 ºC interval<br />

between “grey” solidification and sufficient<br />

undercooling to cause “white”<br />

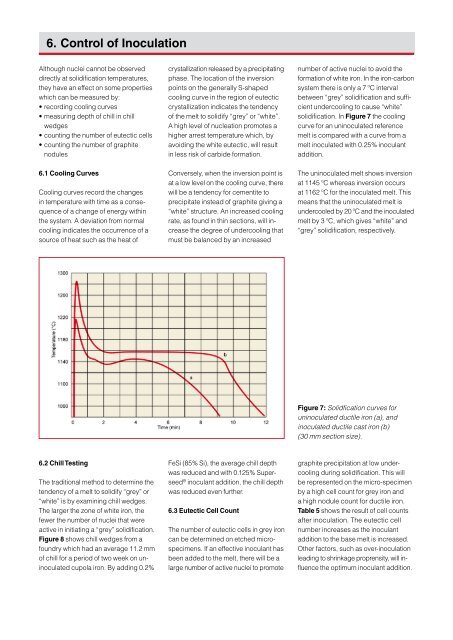

solidification. In Figure 7 the cooling<br />

curve for an uni noculated reference<br />

melt is compared with a curve from a<br />

melt inoculated with 0.25% inoculant<br />

addition.<br />

The uninoculated melt shows inversion<br />

at 1145 ºC whereas inversion occurs<br />

at 1162 ºC for the inoculated melt. This<br />

means that the uninoculated melt is<br />

undercooled by 20 ºC and the inoculated<br />

melt by 3 ºC, which gives “white” and<br />

“grey” solidification, respectively.<br />

Figure 7: Solidfication curves for<br />

uninoculated ductile iron (a), and<br />

inoculated ductile cast iron (b)<br />

(30 mm section size).<br />

6.2 Chill Testing<br />

The traditional method to determine the<br />

tendency of a melt to solidify “grey” or<br />

“white” is by examining chill wedges.<br />

The larger the zone of white iron, the<br />

fewer the number of nuclei that were<br />

active in initiating a “grey” solidification.<br />

Figure 8 shows chill wedges from a<br />

foundry which had an average 11.2 mm<br />

of chill for a period of two week on uninoculated<br />

cupola iron. By adding 0.2%<br />

FeSi (85% Si), the average chill depth<br />

was reduced and with 0.125% Superseed<br />

® inoculant addition, the chill depth<br />

was reduced even further.<br />

6.3 Eutectic Cell Count<br />

The number of eutectic cells in grey iron<br />

can be determined on etched microspecimens.<br />

If an effective inoculant has<br />

been added to the melt, there will be a<br />

large number of active nuclei to promote<br />

graphite precipitation at low undercooling<br />

during solidification. This will<br />

be represented on the micro-specimen<br />

by a high cell count for grey iron and<br />

a high nodule count for ductile iron.<br />

Table 5 shows the result of cell counts<br />

after inoculation. The eutectic cell<br />

number increases as the inoculant<br />

addition to the base melt is increased.<br />

Other factors, such as over-inoculation<br />

leading to shrinkage proprensity, will influence<br />

the optimum inoculant addition.