multivariate production systems optimization - Stanford University

multivariate production systems optimization - Stanford University

multivariate production systems optimization - Stanford University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

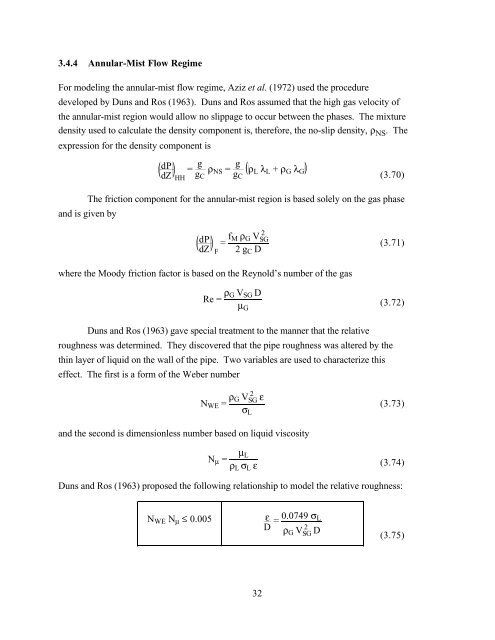

3.4.4 Annular-Mist Flow Regime<br />

For modeling the annular-mist flow regime, Aziz et al. (1972) used the procedure<br />

developed by Duns and Ros (1963). Duns and Ros assumed that the high gas velocity of<br />

the annular-mist region would allow no slippage to occur between the phases. The mixture<br />

density used to calculate the density component is, therefore, the no-slip density, ρNS . The<br />

expression for the density component is<br />

dP =<br />

dZ HH<br />

g<br />

gC ρNS = g<br />

gC ρL λL + ρG λG<br />

32<br />

(3.70)<br />

The friction component for the annular-mist region is based solely on the gas phase<br />

and is given by<br />

dP<br />

dZ F<br />

= fM<br />

2<br />

ρG VSG 2 gC D<br />

where the Moody friction factor is based on the Reynold’s number of the gas<br />

Re = ρG VSG D<br />

μG<br />

Duns and Ros (1963) gave special treatment to the manner that the relative<br />

roughness was determined. They discovered that the pipe roughness was altered by the<br />

thin layer of liquid on the wall of the pipe. Two variables are used to characterize this<br />

effect. The first is a form of the Weber number<br />

NWE = ρG<br />

2<br />

VSG ε<br />

σL<br />

and the second is dimensionless number based on liquid viscosity<br />

Nμ = μL<br />

ρL σL ε<br />

(3.71)<br />

(3.72)<br />

(3.73)<br />

(3.74)<br />

Duns and Ros (1963) proposed the following relationship to model the relative roughness:<br />

NWE Nμ ≤ 0.005<br />

ε =<br />

0.0749 σL<br />

D<br />

2<br />

ρG VSG D<br />

(3.75)