Woodworking Magazine, Spring 2004 - Popular Woodworking ...

Woodworking Magazine, Spring 2004 - Popular Woodworking ...

Woodworking Magazine, Spring 2004 - Popular Woodworking ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Shortcuts<br />

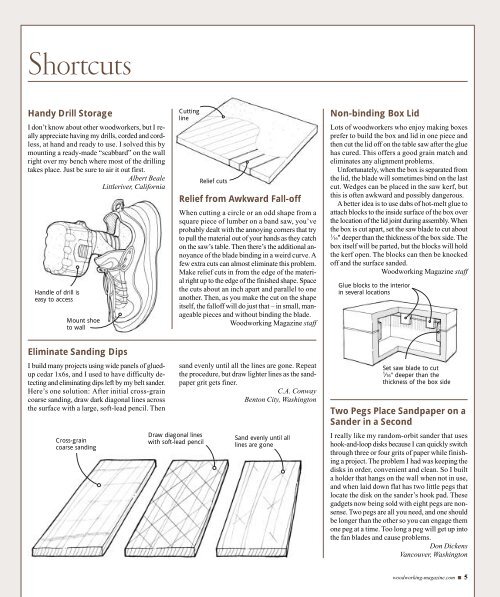

Handy Drill Storage<br />

I don’t know about other woodworkers, but I really<br />

appreciate having my drills, corded and cordless,<br />

at hand and ready to use. I solved this by<br />

mounting a ready-made “scabbard” on the wall<br />

right over my bench where most of the drilling<br />

takes place. Just be sure to air it out first.<br />

Albert Beale<br />

Littleriver, California<br />

Handle of drill is<br />

easy to access<br />

Mount shoe<br />

to wall<br />

Cutting<br />

line<br />

Relief cuts<br />

Relief from Awkward Fall-off<br />

When cutting a circle or an odd shape from a<br />

square piece of lumber on a band saw, you’ve<br />

probably dealt with the annoying corners that try<br />

to pull the material out of your hands as they catch<br />

on the saw’s table. Then there’s the additional annoyance<br />

of the blade binding in a weird curve. A<br />

few extra cuts can almost eliminate this problem.<br />

Make relief cuts in from the edge of the material<br />

right up to the edge of the finished shape. Space<br />

the cuts about an inch apart and parallel to one<br />

another. Then, as you make the cut on the shape<br />

itself, the falloff will do just that – in small, manageable<br />

pieces and without binding the blade.<br />

<strong>Woodworking</strong> <strong>Magazine</strong> staff<br />

Non-binding Box Lid<br />

Lots of woodworkers who enjoy making boxes<br />

prefer to build the box and lid in one piece and<br />

then cut the lid off on the table saw after the glue<br />

has cured. This offers a good grain match and<br />

eliminates any alignment problems.<br />

Unfortunately, when the box is separated from<br />

the lid, the blade will sometimes bind on the last<br />

cut. Wedges can be placed in the saw kerf, but<br />

this is often awkward and possibly dangerous.<br />

A better idea is to use dabs of hot-melt glue to<br />

attach blocks to the inside surface of the box over<br />

the location of the lid joint during assembly. When<br />

the box is cut apart, set the saw blade to cut about<br />

1<br />

⁄16" deeper than the thickness of the box side. The<br />

box itself will be parted, but the blocks will hold<br />

the kerf open. The blocks can then be knocked<br />

off and the surface sanded.<br />

<strong>Woodworking</strong> <strong>Magazine</strong> staff<br />

Glue blocks to the interior<br />

in several locations<br />

Eliminate Sanding Dips<br />

I build many projects using wide panels of gluedup<br />

cedar 1x6s, and I used to have difficulty detecting<br />

and eliminating dips left by my belt sander.<br />

Here’s one solution: After initial cross-grain<br />

coarse sanding, draw dark diagonal lines across<br />

the surface with a large, soft-lead pencil. Then<br />

Cross-grain<br />

coarse sanding<br />

Draw diagonal lines<br />

with soft-lead pencil<br />

sand evenly until all the lines are gone. Repeat<br />

the procedure, but draw lighter lines as the sandpaper<br />

grit gets finer.<br />

C.A. Conway<br />

Benton City, Washington<br />

Sand evenly until all<br />

lines are gone<br />

Set saw blade to cut<br />

1 ⁄16" deeper than the<br />

thickness of the box side<br />

Two Pegs Place Sandpaper on a<br />

Sander in a Second<br />

I really like my random-orbit sander that uses<br />

hook-and-loop disks because I can quickly switch<br />

through three or four grits of paper while finishing<br />

a project. The problem I had was keeping the<br />

disks in order, convenient and clean. So I built<br />

a holder that hangs on the wall when not in use,<br />

and when laid down flat has two little pegs that<br />

locate the disk on the sander’s hook pad. These<br />

gadgets now being sold with eight pegs are nonsense.<br />

Two pegs are all you need, and one should<br />

be longer than the other so you can engage them<br />

one peg at a time. Too long a peg will get up into<br />

the fan blades and cause problems.<br />

Don Dickens<br />

Vancouver, Washington<br />

woodworking-magazine.com ■ 5