Brochure AGV - VDL

Brochure AGV - VDL

Brochure AGV - VDL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

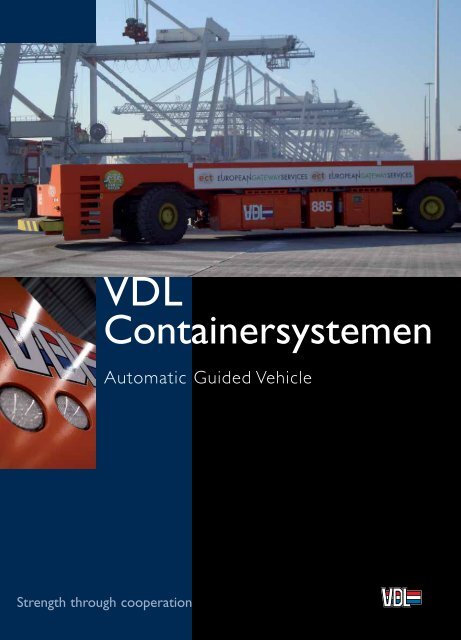

<strong>VDL</strong><br />

Containersystemen<br />

Automatic Guided Vehicle<br />

Strength through cooperation

Automatic Guided Vehicle (<strong>AGV</strong>)<br />

The <strong>AGV</strong> is a fully automated guided vehicle for handling 20’, 40’ and 45’ ISO containers on<br />

main port container terminals. The <strong>VDL</strong> <strong>AGV</strong> can handle loads of up to 70 tonnes with a<br />

maximum speed of 6 metres per second. The available expertise within <strong>VDL</strong> on development<br />

and manufacturing of advanced equipment and vehicles enabled us to develop this high<br />

performance container carrier <strong>AGV</strong> with superior characteristics regarding fuel efficiency, CO 2<br />

emission, noise levels, reliability and maintainability. The result of these efforts is an<br />

environmentally friendly <strong>AGV</strong> with lowest operating costs and highest MTBF* rate. Three <strong>VDL</strong><br />

companies are the major contributors to this successful product development project:<br />

The design of the <strong>AGV</strong> of <strong>VDL</strong> is based<br />

on three criteria:<br />

1. State of the art performance and quality<br />

2. Low total cost of ownership<br />

3. Modularity (easy installation of different<br />

components and the ability to retrofit<br />

new technologies in the future)<br />

• <strong>VDL</strong> Containersystemen with its extensive experience in the field of spreaders for container<br />

and trailer handling purposes is particularly strong in spreaders for Ship to Shore, Yard and<br />

Gantry cranes (RTG / RMG) and Mobile Harbour Cranes. Besides our standard product range<br />

we also develop unique customer specific solutions.<br />

• APTS is expert in the field of engineering electrical controls, power packs and automatic<br />

guidance systems as used in the public transport industry. Solutions in the field of hybrid<br />

power trains, induction and hydrogen<br />

power trains are available within the<br />

company.<br />

• <strong>VDL</strong> Steelweld is the expert in the<br />

field of production automation, logistics<br />

and engineering services. They<br />

design, manufacture and install robotic<br />

production systems. One of its strengths<br />

is the structured approach in integrating<br />

modular solutions.<br />

* Mean time between failures

R&D DEPARTMENT<br />

The ability to listen carefully is one of the<br />

most important qualities of our technical<br />

team. Our experienced specialists want to<br />

know exactly what your requirements are,<br />

as well as the work environment and<br />

local regulations. In addition to maintaining<br />

an up-to-date database with general<br />

industry information, we always discuss<br />

the customer’s specific demands and<br />

requirements: this information forms<br />

the basis for our custom made systems.<br />

IN-HOUSE MANUFACTURING<br />

We have earned our reputation for reliability by continually providing customers optimal<br />

quality. This is why all critical components are manufactured in-house. We also have dedicated<br />

in-house welding, hydraulics and electronics departments, staffed by qualified, experienced<br />

staff who continually strive for perfection. Their work ethic is based on quality, which includes<br />

meticulous product and process monitoring.<br />

SHORT LEAD TIMES<br />

Well-trained craftsmen and a flexible,<br />

efficient organization guarantee competitive<br />

lead times. This immediately<br />

becomes clear when you request an offer,<br />

which is shortly followed by a proposal.<br />

We make sure to maintain that pace for<br />

the duration of the project. This is made<br />

possible through the large amount of<br />

available manufacturing resources within<br />

the <strong>VDL</strong> Groep, allowing us to guarantee<br />

competitive prices and excellent delivery<br />

terms. Our short lead times are also the<br />

result of our organization’s flexible, nononsense<br />

culture.<br />

MODULAR CONSTRUCTION<br />

Designing and building an <strong>AGV</strong> is one thing, delivering vehicles with perfect performance levels<br />

is another. <strong>VDL</strong> follows the latest developments closely and is alert to broaden its knowledge<br />

and experience necessary to deliver state of the art customized products. The <strong>VDL</strong> <strong>AGV</strong> is<br />

modular built, allowing customization and new techniques to be retrofitted if desired. This<br />

design also provides easy service access and quick replacements of parts leading to minimal<br />

down time.<br />

RELIABLE PARTNER<br />

In the transport business, investments are made for the long-term. It’s good to know that <strong>VDL</strong><br />

Containersystemen is a solid company in a successful group. This allows us to guarantee continuity<br />

in the supply of parts, service and maintenance years after purchase. A strong partner with a<br />

strong agent network worldwide, that guarantees optimal accessibility and quick response times.

COMPANY PROFILE<br />

• Over 35 years of harbour experience<br />

• Innovative R&D department<br />

• Completely developed and manufactured in<br />

The Netherlands, under EU regulations<br />

• Specialized in customized solutions<br />

• ISO 9001 and 14001 certified<br />

• VDA 6.4 certified<br />

• Professional advice<br />

• Proven quality<br />

• Short lead times<br />

• In-house welding, electronics and<br />

hydraulics department<br />

• Installation by qualified technicians<br />

• Dedicated service department<br />

• Excellent network of agents<br />

CHARACTERISTICS <strong>VDL</strong> <strong>AGV</strong><br />

• Excellent fuel efficiency<br />

• Low maintenance requirements<br />

• Modular design<br />

• Exchangeable Power pack Unit with<br />

integrated fire extinguishing system<br />

• Supercap hybrid system (readily<br />

available power)<br />

• Low curb weight through use of<br />

high strength steel<br />

• Crab steering<br />

• Real time monitoring & datalogging<br />

• Non-skid coating on container deck<br />

• Unique damping system<br />

• Built in accordance with the highest<br />

environmental standards<br />

VIBRATION REDUCTION THROUGH DAMPING SYSTEM AT CHASSIS LEVEL<br />

Regular <strong>AGV</strong><br />

<strong>VDL</strong> <strong>AGV</strong>

Technical data hybrid <strong>AGV</strong><br />

Maximum load<br />

70 t<br />

Containers 20´ 2x20´ 30´ 40´ 45´<br />

Weight<br />

26 t<br />

Length<br />

14,7 m<br />

Width<br />

3,1 m<br />

Load height<br />

1,7 m<br />

Maximum speed<br />

6 m/s<br />

Maximum corner speed<br />

3 m/s<br />

Acceleration with load<br />

0,5 m/s²<br />

Position accuracy<br />

± 2,5 cm<br />

Engine (optional)<br />

152 kW (257 kW)<br />

Noise emissions<br />

81 dB<br />

Hybrid configuration<br />

Ultracapacitor electrical power supply<br />

Running hours engine<br />

55% of operational use<br />

Power supply by Ultracapacitors 45% of operational use<br />

Diesel consumption<br />

4,8 l/h<br />

Fuel capacity<br />

1000 l<br />

Technical detail<br />

Simulated, tested and proven<br />

force impact absorption by twin<br />

shock absorption<br />

Steering and braking by<br />

independent hydraulic system<br />

Liquid cooled electrical system<br />

Exchangeable powerunit<br />

(Diesel + generator pack)<br />

Interface and complete diagnose at<br />

one screen, 72hrs of datalogging<br />

Key options<br />

Object detection at 30m with<br />

sick scanner<br />

Small size remote control<br />

for maintenance<br />

Tire condition monitoring<br />

Fire extinguisher in Power Pack Unit

<strong>VDL</strong> Groep<br />

<strong>VDL</strong> Containersystemen, <strong>VDL</strong> Steelweld and APTS are part of <strong>VDL</strong> Groep, an international<br />

company with more then 7,600 employees, spread over 81 subsidiaries in 18 countries. The<br />

strength of the cooperation within <strong>VDL</strong> Groep offers added assurance in terms of continuity to<br />

customers and suppliers of <strong>VDL</strong> alike.<br />

<strong>VDL</strong> Containersystemen and <strong>VDL</strong> Steelweld operate in the finished products division. This division<br />

comprises suspension systems for the automotive industry, heating, cooling and air-technical<br />

systems, systems for the oil, gas and petrochemical industry, production automation systems,<br />

systems for the agricultural sector, sunbeds, roof boxes, container handling equipment,<br />

cigar-making and packaging machines, components for bulkhandling and dust extraction<br />

installations and systems for explosion and fire protection.<br />

The other divisions are subcontracting and buses & coaches where APTS operates. In<br />

subcontracting, <strong>VDL</strong> specialises in metalworking, mechatronic systems and system supply,<br />

plastics processing and surface treatment. The bus & coach division includes chassis modules,<br />

coaches, public transport buses, mini & midi buses and second-hand buses.<br />

<strong>VDL</strong> Containersystemen bv<br />

Industrieweg 21<br />

5527 AJ Hapert<br />

P.O. Box 99<br />

5527 ZH Hapert<br />

The Netherlands<br />

Phone +31 (0)497 - 38 70 50<br />

Fax +31 (0)497 - 38 68 55<br />

sales@vdlcontainersyst.nl<br />

www.vdlcontainersystemen.com