Review of diesel particulate matter sampling - Department of ...

Review of diesel particulate matter sampling - Department of ...

Review of diesel particulate matter sampling - Department of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

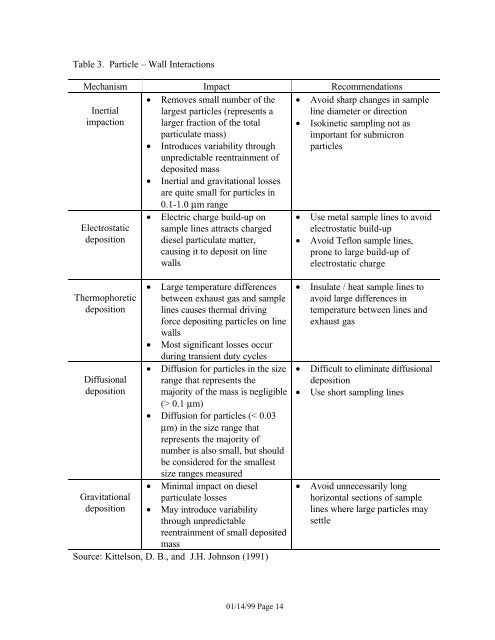

Table 3. Particle – Wall Interactions<br />

Mechanism Impact Recommendations<br />

Inertial<br />

impaction<br />

Electrostatic<br />

deposition<br />

Thermophoretic<br />

deposition<br />

Diffusional<br />

deposition<br />

Gravitational<br />

deposition<br />

• Removes small number <strong>of</strong> the<br />

largest particles (represents a<br />

larger fraction <strong>of</strong> the total<br />

<strong>particulate</strong> mass)<br />

• Introduces variability through<br />

unpredictable reentrainment <strong>of</strong><br />

deposited mass<br />

• Inertial and gravitational losses<br />

are quite small for particles in<br />

0.1-1.0 μm range<br />

• Electric charge build-up on<br />

sample lines attracts charged<br />

<strong>diesel</strong> <strong>particulate</strong> <strong>matter</strong>,<br />

causing it to deposit on line<br />

walls<br />

• Large temperature differences<br />

between exhaust gas and sample<br />

lines causes thermal driving<br />

force depositing particles on line<br />

walls<br />

• Most significant losses occur<br />

during transient duty cycles<br />

• Diffusion for particles in the size<br />

range that represents the<br />

majority <strong>of</strong> the mass is negligible<br />

(> 0.1 μm)<br />

• Diffusion for particles (< 0.03<br />

μm) in the size range that<br />

represents the majority <strong>of</strong><br />

number is also small, but should<br />

be considered for the smallest<br />

size ranges measured<br />

• Minimal impact on <strong>diesel</strong><br />

<strong>particulate</strong> losses<br />

• May introduce variability<br />

through unpredictable<br />

reentrainment <strong>of</strong> small deposited<br />

mass<br />

Source: Kittelson, D. B., and J.H. Johnson (1991)<br />

01/14/99 Page 14<br />

• Avoid sharp changes in sample<br />

line diameter or direction<br />

• Isokinetic <strong>sampling</strong> not as<br />

important for submicron<br />

particles<br />

• Use metal sample lines to avoid<br />

electrostatic build-up<br />

• Avoid Teflon sample lines,<br />

prone to large build-up <strong>of</strong><br />

electrostatic charge<br />

• Insulate / heat sample lines to<br />

avoid large differences in<br />

temperature between lines and<br />

exhaust gas<br />

• Difficult to eliminate diffusional<br />

deposition<br />

• Use short <strong>sampling</strong> lines<br />

• Avoid unnecessarily long<br />

horizontal sections <strong>of</strong> sample<br />

lines where large particles may<br />

settle