KOV piston pumps with ball valves - Pmw.co.in

KOV piston pumps with ball valves - Pmw.co.in

KOV piston pumps with ball valves - Pmw.co.in

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

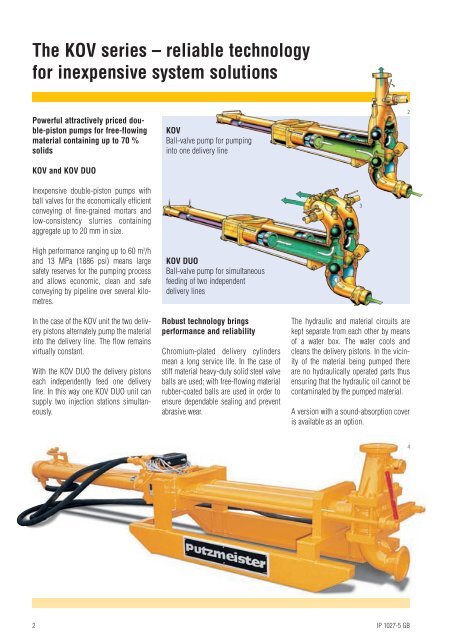

The <strong>KOV</strong> series – reliable technology<br />

for <strong>in</strong>expensive system solutions<br />

Powerful attractively priced double-<strong>piston</strong><br />

<strong>pumps</strong> for free-flow<strong>in</strong>g<br />

material <strong>co</strong>nta<strong>in</strong><strong>in</strong>g up to 70 %<br />

solids<br />

<strong>KOV</strong> and <strong>KOV</strong> DUO<br />

<strong>KOV</strong><br />

Ball-valve pump for pump<strong>in</strong>g<br />

<strong>in</strong>to one delivery l<strong>in</strong>e<br />

2<br />

Inexpensive double-<strong>piston</strong> <strong>pumps</strong> <strong>with</strong><br />

<strong>ball</strong> <strong>valves</strong> for the e<strong>co</strong>nomically efficient<br />

<strong>co</strong>nvey<strong>in</strong>g of f<strong>in</strong>e-gra<strong>in</strong>ed mortars and<br />

low-<strong>co</strong>nsistency slurries <strong>co</strong>nta<strong>in</strong><strong>in</strong>g<br />

aggregate up to 20 mm <strong>in</strong> size.<br />

3<br />

High performance rang<strong>in</strong>g up to 60 m 3 /h<br />

and 13 MPa (1886 psi) means large<br />

safety reserves for the pump<strong>in</strong>g process<br />

and allows e<strong>co</strong>nomic, clean and safe<br />

<strong>co</strong>nvey<strong>in</strong>g by pipel<strong>in</strong>e over several kilometres.<br />

In the case of the <strong>KOV</strong> unit the two delivery<br />

<strong>piston</strong>s alternately pump the material<br />

<strong>in</strong>to the delivery l<strong>in</strong>e. The flow rema<strong>in</strong>s<br />

virtually <strong>co</strong>nstant.<br />

With the <strong>KOV</strong> DUO the delivery <strong>piston</strong>s<br />

each <strong>in</strong>dependently feed one delivery<br />

l<strong>in</strong>e. In this way one <strong>KOV</strong> DUO unit can<br />

supply two <strong>in</strong>jection stations simultaneously.<br />

<strong>KOV</strong> DUO<br />

Ball-valve pump for simultaneous<br />

feed<strong>in</strong>g of two <strong>in</strong>dependent<br />

delivery l<strong>in</strong>es<br />

Robust technology br<strong>in</strong>gs<br />

performance and reliability<br />

Chromium-plated delivery cyl<strong>in</strong>ders<br />

mean a long service life. In the case of<br />

stiff material heavy-duty solid steel valve<br />

<strong>ball</strong>s are used; <strong>with</strong> free-flow<strong>in</strong>g material<br />

rubber-<strong>co</strong>ated <strong>ball</strong>s are used <strong>in</strong> order to<br />

ensure dependable seal<strong>in</strong>g and prevent<br />

abrasive wear.<br />

The hydraulic and material circuits are<br />

kept separate from each other by means<br />

of a water box. The water <strong>co</strong>ols and<br />

cleans the delivery <strong>piston</strong>s. In the vic<strong>in</strong>ity<br />

of the material be<strong>in</strong>g pumped there<br />

are no hydraulically operated parts thus<br />

ensur<strong>in</strong>g that the hydraulic oil cannot be<br />

<strong>co</strong>ntam<strong>in</strong>ated by the pumped material.<br />

A version <strong>with</strong> a sound-absorption <strong>co</strong>ver<br />

is available as an option.<br />

4<br />

2<br />

IP 1027-5 GB

![Data sheet BSA 1005 E (TB 1186) [.pdf; 278.88 kb]](https://img.yumpu.com/40181054/1/184x260/data-sheet-bsa-1005-e-tb-1186-pdf-27888-kb.jpg?quality=85)

![(BP 3531) [.pdf; 221.30 kb] - Putzmeister Concrete Machines Pvt. Ltd.](https://img.yumpu.com/35322592/1/184x260/bp-3531-pdf-22130-kb-putzmeister-concrete-machines-pvt-ltd.jpg?quality=85)

![Data sheet M 70-5 (BP 4311) [.PDF (kb383); 721.22 kb] - Putzmeister](https://img.yumpu.com/29333530/1/184x260/data-sheet-m-70-5-bp-4311-pdf-kb383-72122-kb-putzmeister.jpg?quality=85)