KOV piston pumps with ball valves - Pmw.co.in

KOV piston pumps with ball valves - Pmw.co.in

KOV piston pumps with ball valves - Pmw.co.in

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

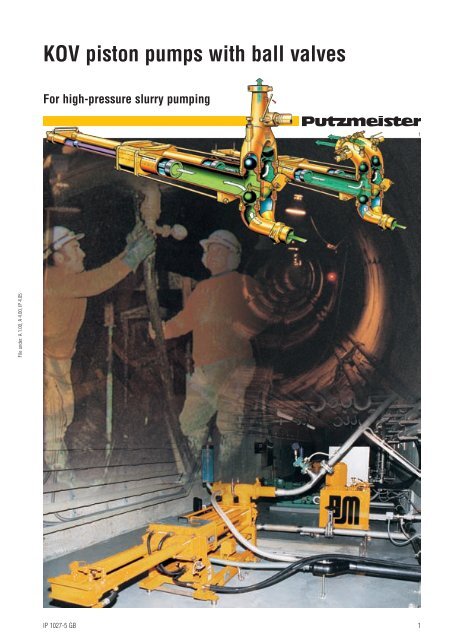

<strong>KOV</strong> <strong>piston</strong> <strong>pumps</strong> <strong>with</strong> <strong>ball</strong> <strong>valves</strong><br />

For high-pressure slurry pump<strong>in</strong>g<br />

1<br />

File under: A 1.00, A 4.00, IP 4.05<br />

IP 1027-5 GB<br />

1

The <strong>KOV</strong> series – reliable technology<br />

for <strong>in</strong>expensive system solutions<br />

Powerful attractively priced double-<strong>piston</strong><br />

<strong>pumps</strong> for free-flow<strong>in</strong>g<br />

material <strong>co</strong>nta<strong>in</strong><strong>in</strong>g up to 70 %<br />

solids<br />

<strong>KOV</strong> and <strong>KOV</strong> DUO<br />

<strong>KOV</strong><br />

Ball-valve pump for pump<strong>in</strong>g<br />

<strong>in</strong>to one delivery l<strong>in</strong>e<br />

2<br />

Inexpensive double-<strong>piston</strong> <strong>pumps</strong> <strong>with</strong><br />

<strong>ball</strong> <strong>valves</strong> for the e<strong>co</strong>nomically efficient<br />

<strong>co</strong>nvey<strong>in</strong>g of f<strong>in</strong>e-gra<strong>in</strong>ed mortars and<br />

low-<strong>co</strong>nsistency slurries <strong>co</strong>nta<strong>in</strong><strong>in</strong>g<br />

aggregate up to 20 mm <strong>in</strong> size.<br />

3<br />

High performance rang<strong>in</strong>g up to 60 m 3 /h<br />

and 13 MPa (1886 psi) means large<br />

safety reserves for the pump<strong>in</strong>g process<br />

and allows e<strong>co</strong>nomic, clean and safe<br />

<strong>co</strong>nvey<strong>in</strong>g by pipel<strong>in</strong>e over several kilometres.<br />

In the case of the <strong>KOV</strong> unit the two delivery<br />

<strong>piston</strong>s alternately pump the material<br />

<strong>in</strong>to the delivery l<strong>in</strong>e. The flow rema<strong>in</strong>s<br />

virtually <strong>co</strong>nstant.<br />

With the <strong>KOV</strong> DUO the delivery <strong>piston</strong>s<br />

each <strong>in</strong>dependently feed one delivery<br />

l<strong>in</strong>e. In this way one <strong>KOV</strong> DUO unit can<br />

supply two <strong>in</strong>jection stations simultaneously.<br />

<strong>KOV</strong> DUO<br />

Ball-valve pump for simultaneous<br />

feed<strong>in</strong>g of two <strong>in</strong>dependent<br />

delivery l<strong>in</strong>es<br />

Robust technology br<strong>in</strong>gs<br />

performance and reliability<br />

Chromium-plated delivery cyl<strong>in</strong>ders<br />

mean a long service life. In the case of<br />

stiff material heavy-duty solid steel valve<br />

<strong>ball</strong>s are used; <strong>with</strong> free-flow<strong>in</strong>g material<br />

rubber-<strong>co</strong>ated <strong>ball</strong>s are used <strong>in</strong> order to<br />

ensure dependable seal<strong>in</strong>g and prevent<br />

abrasive wear.<br />

The hydraulic and material circuits are<br />

kept separate from each other by means<br />

of a water box. The water <strong>co</strong>ols and<br />

cleans the delivery <strong>piston</strong>s. In the vic<strong>in</strong>ity<br />

of the material be<strong>in</strong>g pumped there<br />

are no hydraulically operated parts thus<br />

ensur<strong>in</strong>g that the hydraulic oil cannot be<br />

<strong>co</strong>ntam<strong>in</strong>ated by the pumped material.<br />

A version <strong>with</strong> a sound-absorption <strong>co</strong>ver<br />

is available as an option.<br />

4<br />

2<br />

IP 1027-5 GB

5<br />

6<br />

<strong>KOV</strong> double-<strong>piston</strong> <strong>pumps</strong> are<br />

the ideal solution for a wide<br />

range of applications<br />

■ Mortar <strong>in</strong>jection<br />

■ Remov<strong>in</strong>g slurry from tunnels<br />

■ Desludg<strong>in</strong>g bodies of water<br />

■ Pump<strong>in</strong>g fly ash<br />

■ Pressure grout<strong>in</strong>g<br />

■ Digested biomass<br />

TRIA - <strong>co</strong>nt<strong>in</strong>uous fill<strong>in</strong>g of annular space as r<strong>in</strong>g<br />

segments are removed beh<strong>in</strong>d the tunnell<strong>in</strong>g<br />

mach<strong>in</strong>e<br />

Sure <strong>co</strong>ntrol of the pumped<br />

output even over large distances<br />

7 8<br />

When hydraulic units are used <strong>in</strong> <strong>co</strong>njunction<br />

<strong>with</strong> programmable <strong>co</strong>ntrollers<br />

it is possible to <strong>co</strong>ntrol the pump<strong>in</strong>g<br />

system over large distances. The pump<br />

output can be adjusted as desired via a<br />

4 – 20 mA signal and the pressure limited<br />

either hydraulically or electrically.<br />

A manual output adjustment is a standard<br />

feature.<br />

Remov<strong>in</strong>g slurry from a tunnel<br />

9<br />

Save your time and money <strong>in</strong><br />

ma<strong>in</strong>tenance and service<br />

Ma<strong>in</strong>tenance work on the <strong>in</strong>expensive<br />

but robust ma<strong>in</strong> wear<strong>in</strong>g parts is quick<br />

and straightforward to carry out. This<br />

reduces <strong>co</strong>sts and downtimes.<br />

A <strong>KOV</strong> 1050 <strong>pumps</strong> the <strong>in</strong>jection mortar beh<strong>in</strong>d<br />

the r<strong>in</strong>g segment<br />

Pump<strong>in</strong>g lime slurry<br />

10<br />

Delivery l<strong>in</strong>es<br />

The <strong>KOV</strong> can be supplemented <strong>with</strong> a<br />

wide range of different pipe systems –<br />

especially tailored to your special application.<br />

Space-sav<strong>in</strong>g <strong>in</strong>stallation of two <strong>KOV</strong> 550 DUO<br />

underneath a 6 m 3 agitat<strong>in</strong>g trough<br />

IP 1027-5 GB<br />

3

Technical Data <strong>KOV</strong><br />

Type Max. output Output pressure Delivery cyl. length Delivery cyl. Ø Length (L) Width (W) Height (H)<br />

m 3 /h MPa / psi mm mm mm mm mm<br />

<strong>KOV</strong> 550 25 13.0 / 1886 500 180 2250 730 920<br />

<strong>KOV</strong> 1020 11 5.5 / 798 1000 100 3000 600 980<br />

<strong>KOV</strong> 1050 36 13.0 / 1886 1000 180 3300 730 1050<br />

<strong>KOV</strong> 1450 50 13.0 / 1886 1400 180 4100 730 1050<br />

<strong>KOV</strong> 2160 60 13.0 / 1886 2100 200 4600 1100 1300<br />

<strong>KOV</strong> 550 DUO 2 x 15 13.0 / 1886 500 180 2250 1100 920<br />

<strong>KOV</strong> 1020 DUO 2 x 5,5 5.5 / 798 1000 100 3000 600 980<br />

<strong>KOV</strong> 1050 DUO 2 x 18 13.0 / 1886 1000 180 3300 1100 920<br />

The figures quoted above should be regarded as guidel<strong>in</strong>es and actual values will depend on the <strong>in</strong>dividual application.<br />

Please <strong>co</strong>ntact us for a detailed offer.<br />

W<br />

11<br />

H<br />

L<br />

Member of the Putzmeister Group<br />

www.putzmeister.<strong>co</strong>m<br />

Right to make technical amendments reserved<br />

© by Putzmeister Solid Pumps GmbH 2010<br />

All rights reserved<br />

Pr<strong>in</strong>ted <strong>in</strong> Germany<br />

(11004SC)<br />

Putzmeister Solid Pumps GmbH<br />

Max-Eyth-Straße 10 · 72631 Aichtal/Germany<br />

P.O.Box 2152 · 72629 Aichtal/Germany<br />

Tel. +49 7127 599-500 · Fax +49 7127 599-988<br />

psp@pmw.de · www.putzmeister-solid-<strong>pumps</strong>.<strong>co</strong>m<br />

4<br />

IP 1027-5 GB

![Data sheet BSA 1005 E (TB 1186) [.pdf; 278.88 kb]](https://img.yumpu.com/40181054/1/184x260/data-sheet-bsa-1005-e-tb-1186-pdf-27888-kb.jpg?quality=85)

![(BP 3531) [.pdf; 221.30 kb] - Putzmeister Concrete Machines Pvt. Ltd.](https://img.yumpu.com/35322592/1/184x260/bp-3531-pdf-22130-kb-putzmeister-concrete-machines-pvt-ltd.jpg?quality=85)

![Data sheet M 70-5 (BP 4311) [.PDF (kb383); 721.22 kb] - Putzmeister](https://img.yumpu.com/29333530/1/184x260/data-sheet-m-70-5-bp-4311-pdf-kb383-72122-kb-putzmeister.jpg?quality=85)