2005 - Putzmeister

2005 - Putzmeister

2005 - Putzmeister

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ContentsLatest News2PM 3723 GB34Latest NewsRecord number of participantsInformation from VDMAColossal hangars for superjumbosTitle StoryRefurbishment121525Not as easy as you think –Diamant Mühle Hamburg refurbishmentBuilding constructionLarge construction site16Power station constructionin Canada's wildernessBackground102024Technology14"Quintuplet" adapts itselfBetween sun and seaNumerous concrete pumpsat Germany's largest construction siteSpecial concrete2226New machinery means ideallyequipped to competeHigh quality requirements even in theconstruction of model concrete pumpsTen in a rowFlexible 20 m "quad" –Universal truck-mounted concrete pumpwith an unfolding height of just 3.9 mConcrete placement on 109 m high pitframeLarge boom concrete pumps inject"Bügelbauten" bookend buildingsApplication28Concreting on water2252043 4new!1621462426101278910Record number ofparticipantsIn December, the <strong>Putzmeister</strong> Academy islooking forward to a record number ofseminar participants for the <strong>2005</strong> trainingseason. Within a year, over 1,100<strong>Putzmeister</strong> guests from all continents willhave achieved further qualification in 61customer seminars. The one- to five-daycourses are held either at <strong>Putzmeister</strong>'s premisesin Aichtal or directly at the customer'spremises. The contents are aimed atthe operators of concrete pumps and at themachine maintenance staff (mechanics,workshop managers).In order to reach as many participants aspossible in their respective mother tongues,the PM Academy trainers offer the individualcourses not only in German andEnglish, but also in French and Spanish.Translation into other languages, such asArabic, Russian, Chinese, etc. is carried outon-site by qualified interpreters, dependingon the composition of the group ofparticipants.For seminar season 2006, the <strong>Putzmeister</strong>Academy has again extended its range ofcourses. For more information, and to registerfor a seminar online, see:www.pm-akademie.deInformation from the GermanAssociation of Machine andPlant Engineering (VDMA)The Chinese STATE DEVELOPMENT &INVESTMENT CORP is planning toinvest approximately USD 17.3 billion inthe construction of six hydroelectric powerstations at the upper reaches of theYangtzee (Sichuan Province). One of theprojects has already been approved by theresponsible authorities and is to join themains supply by 2012.It is estimated that the construction of theMessina bridge, one of the largest Italianinfrastructure projects, will start in spring2006. The contract to construct the 3.3 kmlong suspension bridge over the Strait ofMessina was awarded to a consortiumunder the management of the Italian constructioncompany IMPREGILO. The consortiumalso includes the Japanese companyISHIKAWAJIMA HARIMA HEAVYINDUSTRIES, the Spanish companySACYR VALEHERMOSO and otherItalian construction firms. The two towersof the bridge will be higher than the EiffelTower, at 383 m each. The costs of thebridge designed for road and rail traffic, isestimated at EUR 3.88 billion.Colossal hangarsfor superjumbosDubai International Airport, the majorinternational gateway in the United ArabEmirates, has been expanding since 2002thanks to investment totalling $ 4.1 US billion.The project mainly involves the constructionof a third passenger terminal, twoconcourses and one enormous air cargocentre. Completion of the project will triplethe airport’s annual capacity from 22 millionto 60 million passengers. This increase incapacity will be made possible by theintroduction of modern superjumbo aeroplanes.In addition to the expansion of the takeoffand landing strips of Dubai InternationalAirport, there is another major projectunderway. A gigantic hangar complex isunder construction in which it will also bepossible to carry out demanding maintenancework on any of the models in therapidly expanding fleet of EMIRATESAIRLINE and its contractual partners. Thehangars are dimensioned to even be able tohouse AIRBUS A380 superjumbos with awingspan of almost 80 m. EMIRATESAIRLINE has already ordered 45 of thesesuperjumbos, which have ample room forup to 850 passengers.The new “Emirates Engineering Center”includes eight hangars, workshops, a washingzone, an aeroplane painting facility,office space, two taxiways, a mosque and apowerplant. The <strong>Putzmeister</strong> BSF 42.16 Hshown below will also be used for theextensive concreting work.113PM 3723 GB

Title StoryPower station constructionin Canada's wilderness –1200 km from thenearest servicesupport pointThe on-going energy development ofHydro-Québec is part of a $2 billion projectundertaken by SEBJ – SocieteEnergie de Baie James. For Hydro-Québec, SEBJ has been instrumental inthe development of a very rich hydroelectricarea via numerous power stationsinstalled since the 1970s. The newEastmain-1 hydroelectric power plant –located on the Eastmain River near JamesBay – is designed to generate 480 megawattof electric power for Hydro-Québec.This was preceded by extensive negotiationswith the Cree Indian clans resident inthe region. Several different <strong>Putzmeister</strong>machines are being used here in theCanadian wilderness – far from anyservice support point.The enormous project – underway in adesolate region in northern Québec – includesa powerhouse, a main dam across theEastmain River, the spillway on the rightbank of the river, and 33 dikes for reservoirclosure. The construction of the project'scomplex was broken down into five majorcontracts, awarded independently via openpublic bids.12The largest of all structures being built isthe 50 m tall, 125 m long and 55 m widepowerhouse – where three huge turbineswill generate the power. This surfacepowerhouse, built into a rocky hill, is onthe left bank of the Eastmain River. By thetime the water exits through the tailrace, itwill have dropped over 60 m from thewater intake. This head, combined with theflow, develops kinetic energy that causesthe turbines and generators to turn, producingelectricity.In particular, the major $ 108 millionCanadian powerhouse, penstocks, andwater intake project were started in thespring of 2004 under the direction ofCanadian contractor AECON HOCHTIEF.The AECON Group is one of Canada'slargest publicly traded construction companies,and the group is 49 %-owned byGerman construction giant HOCHTIEF.Upon completion in early 2006, the reputablegeneral contractor will have pumpedover 46,000 m 3 of concrete. This amountsto about two-thirds of the total 68,000 m 3needed for the entire project.Aggregates of granite, a little water andlow cement contentIn order to guarantee the most economicconcrete placement possible, in addition toefficient concrete manufacture, the sitemanagement is absolutely dependent onreliable machine equipment. For, in thisremote area, the failure of machines wouldlead to extremely high costs – Montreal,the nearest big city, is over 1,200 km away.For this reason, AECON HOCHTIEFdecided on the Canadian representation of<strong>Putzmeister</strong>, POMPACTION Inc., fromPointe-Claire. It delivers practically all theconcreting equipment to the remote constructionsite in the extremely sparselypopulated north-east of the country.Project Manager Ken Chryssolor ofAECON HOCHTIEF said, "For over 30years, I've worked on huge jobs withinJames Bay so I know how difficult theabrasive granite mix is to pump. As weneeded high performance equipment thatcould handle the tough aggregate mix, we'redepending on all <strong>Putzmeister</strong> products."Shorter boom for thicker linesFor the specific powerhouse and waterintake project, the mix of equipmentincludes two BSA 2109 H-D high pressuretrailer-mounted concrete pumps, a JT 5000jumbo trough mixer, and two PM towersfor mounting specially modified MXR30 Z-150 separate placing booms. The two<strong>Putzmeister</strong> placing booms were originallystandard MXR 34 Z-125 units modified byshortening the boom length to 30 meters tomake up for the weight difference in usingthe 150 mm pipe required.Instead of typical 125 mm pipe, 150 mmdiameter was needed throughout the deliverysystem in handling the extremely harshconcrete mix supplied by the on-site batchplant. The brutal mix comprises crushedgranite at 38 mm wide yet an inconceivable100 mm long. Due to the abrasive mix, highpressures, and up to 150 mm pumping distancesinvolved, <strong>Putzmeister</strong> ZX pipes andcouplings are also being used. In addition,with generally lower water/cement values,the concretes for many constructional elementshave hardly any free water and thecement content is often significantly reducedin order to reduce the hydration heat.Particularly hard-wearingZX delivery lines"We needed heavy duty pipe and couplingsfor handling the extremely hard aggregatemix and for long usage life.Title Story<strong>Putzmeister</strong> introduces three variants ofthe ZX coupling system to the program:The ZX-Sthreaded coupling is especially suitedto quick assembly of delivery lines which areseldom or never rerouted.PM recommendsthe ZX-K wing-head coupling for quickassembly of delivery lines that have to be installedmore frequently.The ZX-W wedged coupling wasdeveloped so that delivery lines can be opened atlightning speed, for example at emptying stations orcleaning connections.<strong>Putzmeister</strong>'s special ZX pipe and couplingsare completely leak-proof and high-pressureresistant. They definitely outlast any standardpipe and are an absolute necessity forthis application," Ken noted.Two <strong>Putzmeister</strong> BSA 2109 H-D trailermountedconcrete pumps were also selectedbecause of their field proven S-valve forhandling the coarse mix. They would alsohelp keep wear costs to a minimum withtheir inherently long 2100 mm strokecylinders and up to 152 bar high-pressurecapabilities.14151613Without a set pattern, pumping occurs onan irregular basis. Average outputs rangebetween 20 to 60 m 3 /h with the rate ofplacement governed by the specificationsand the complexity of the intricate forms,not by the equipment capabilities.View of the dam of the Eastmain-1 hydroelectric power plant in north-east Canada.The outlet tunnels are shown in the left of the picture (Photo: SEBJ)4PM 3723 GBThe concrete contains aggregates with anedge length of up to 100 mm5PM 3723 GB

Title StoryTitle StoryConcrete mixing trough as anadditional "buffer"Of the two trailer pumps, one serves as themain production unit being fed via a<strong>Putzmeister</strong> JT-5000 jumbo trough – a surgehopper directly flanged to the pump's hopper.The jumbo trough with a concretecapacity of 5 m 3 allows a quick and fulldischarge of the mixer trucks into its largecapacity hopper. The buffer function of themixing trough means it is also possible tocontinuously supply the main pump (max.output 95 m 3 /h) with concrete.The second <strong>Putzmeister</strong> trailer pump servesas backup because cold joints are absolutelyforbidden or the powerhouse would bestructurally deficient. Consequently, in caseof an equipment malfunction, the secondpump can finish a pour.Ken said, "We basically have to almostduplicate equipment needs because of ourremote location 15 hours away fromMontreal. With 600 men on a job, we can'tafford down time. Fortunately, no majorproblems have resulted to-date, and theequipment has performed to our demandingexpectations."17From April to November 2004, concretework for the powerhouse took place. Two24 m tall placing boom towers wereanchored with bolts and had to be preciselymounted in specified locations so no coldjoints would interfere with the flow ofwater upon project completion."Z" folds show their strengths underthe roofThe two placing booms – each using theirfull 30 m horizontal reach – first providedfull coverage to place concrete for both thewalls of the huge turbines and the powerhousestructure itself.In November, the two towers were movedto handle the intake structure. This time,they were supported by 4.5 m x 4.5 m x1.2 m high poured concrete mats, and theplacing booms still provided ample reachto all concrete placing areas.Especially noteworthy is the placingboom's Multi-Z boom configuration, whichproved exceptionally maneuverable inworking under the low roof of a temporaryoverhead steel structure. The structure wasspecially built so construction could continueduring the frigid winter months.AECON HOCHTIEF is also handling thehorizontal concrete work for the penstocks.The three enormous penstocks are concretelinedconduits excavated in the rock tochannel water from the reservoir to thepowerhouse turbines and are designed tomaximize the head (drop in level).A <strong>Putzmeister</strong> BSA 2109 H-D trailer pumpis pumping the concrete lining of these107 m long penstocks, each at a 7.6 m diameterranging from a 0.3 m to 1.2 mthickness.Important: reliable machinesa n d good serviceBesides the equipment's proven performance,service and support capabilities were asignificant factor in AECON HOCHTIEFselecting POMPACTION for their equipmentneeds. POMPACTION assisted inspecifying the appropriate equipment, helpedtrain operators, and is making servicecalls when deemed necessary.19Project manager Ken Chryssolor(Photo: AECON HOCHTIEF)18The two PM MX 30 stationary booms are installed in 24 m high lattice towers (Photo: POMPACTION)20A Stationary concrete pump BSA 2109 H-DB „Jumbo“ Trough mixer JT 5000C ZX delivery lineBAC6PM 3723 GBA MX 30 used for concrete placement in the turbine house. One of the inlet tunnels is shown in the background (Photo: SEBJ)7PM 3723 GB

Title StoryTitle StoryAnd making service calls isn't easy. As aclosed site, entry is by invitation only viaSEBJ (Air Creebec) aircraft or a 15-hourdrive from Montreal. That's why a speciallydeveloped workcamp was built to houseconstruction site workers, who in staggeringshifts work 42 days followed by a tendayleave.During a peak period in summer 2004,nearly 2,400 workers were housed in dormitories.Work is carried out in alternatingshifts, each lasting 42 days. There are thenten days free. Similar to a mini-town, thesite offers a variety of services such as cafeteria,hair salon, convenience store, postoffice and library along with indoor andoutdoor recreational facilities.Once the project is complete, the approximate1.3 km 3 workcamp will be dismantledand transported to another job site.The TELEBELT was used to deliver hardcore,sand, broken rock and also concrete to thelarge construction site21Even the DYNAJET high-pressure cleanerswere on-site working six months forNEILSON CONSTRUCTION of QuébecCity. Next to the dam, two 500th modelssprayed water at high 500 bar pressures tothoroughly clean selective areas of rockbefore concrete placement was possible.In summary, Francis Gagnier, VicePresident at POMPACTION said, "We'vesold several different pieces of <strong>Putzmeister</strong>equipment to various contractors workingon this enormous and demanding projectcomplex. That alone is valid testimony tothe value placed on the equipment's performanceand reliability within such a remotelocation."As of spring <strong>2005</strong>, the entire Eastmain-1project was 66 % complete. Plans are forthe facility to be operational by late 2006.2324Wide rangeBesides building the concrete intensivepowerhouse, other construction projects onsite are also utilizing various <strong>Putzmeister</strong>models, resulting in basically a monopolyof <strong>Putzmeister</strong> equipment on Eastmain-1.This includes a BSA 1409 electric-poweredtrailer pump being used by NORASCON-HEBERT joint venture, two companieswell established in Québec. The unit iscompetently placing concrete for all inclinework associated with the penstocks.In addition, a TELEBELT TB 105 belt conveyorwas utilized for placing concrete onthe main dam across the Eastmain River.The contractor, HAMEL CONSTRUCT-ION took full advantage of the conveyor'sspecial functionality to place unusuallytough mixes and other aggregates such assand, gravel and rock with ease.For construction of the numerous dams,various Thom-Katt trailer-mounted pumpmodels were utilized for shotcreting byNORASCON-HEBERT and also by EDMCONSTRUCTION, who were sub-contractedby CCDC in Montreal. In addition,a <strong>Putzmeister</strong> P-11 diesel-poweredrotor/stator pump handled injection groutingfor EBC, Inc.We would like to thank POMPACTION,PM America and Sheila Eden for theirassistance with this article.Self-confident First Nations peoplesThe Cree people are now one of the largestFirst Nations groups in North America.Their settlement area stretches from theRocky Mountains to the Atlantic coast, inthe north of the USA and in the south ofCanada. The Cree people speak theAlgonquin language and have their ownwritten language.With a DYNAJET high pressure cleaner and up to 500bar water pressure, a worker removes the loose stonefrom the rock surface.25The large scale Eastmain-1 camp has all the conveniences of a small town (PHOTO: SEBJ)22After years of dispute over the dam projectin their Reserve at James Bay, several clansof the Canadian Cree Indians, such as theMistissini, the Nemaska and the Waskganish,agreed to a negotiation compromise betweenthe provincial government of Québec andtheir chieftains in February 2002, after anagreement was reached among the clanmembers in the nine villages of the Reserve.268PM 3723 GBAccording to this agreement, the Creepeople will receive a total of 3.4 billionCanadian dollars (approximately EUR 2.4billion) over a period of 50 years as compensationfor the construction of dams atthe Eastmain and Ruppert Rivers, and ascompensation for the flooded areas. TheCree people want to use the money todevelop the economy, the infrastructure andliving space. The negotiated compromisewas strongly disputed, especially amongthe younger members of the clans.Today, there are around 1 million "FirstNations" or "Inuit" people. The first inhabitantsof Canada are supposed to have reachedthe country via a land bridge from Siberiato Alaska. The first contact betweenEuropeans and the First Nations peopleoccurred around 1,000 years ago whenVikings settled predominantly in Newfoundland.Due to its rich supply of oil and gas,Canada is today one of the leading energyexporters in the world. However, extortionateamounts are spent on using naturalenergy resources in their own country.Today, Canada has 31.5 million inhabitants(Germany: 81.5 million) and covers an areaof approximately 10 million km 2 (Germany:0.357 million km 2 ).The population density is around 3 peopleper km 2 (Germany: 231 inhabitants per km 2 ).9PM 3723 GB

BackgroundNew machinery means ideallyequipped to compete28AUSTRIAN ARABIAN READY MIXCONCRETE was newly established in2004. Two new concrete mixing plants,50 truck mixers and six <strong>Putzmeister</strong> truckmountedconcrete pumps imported only afew months ago make the concrete manufacturerand pumping service providerwith its modern machinery ideally equippedto face the rigourous competition in theUnited Arab Emirates.2910PM 3723 GBAUSTRIAN ARABIAN opted for the spaciousarea in Jebel Ali, approximately 25 kmSouth West of Dubai, for its strategicallylocated site. Construction will begin nearhere on a new airport this year and theisland world of Palm Jumeirah off the coastwill not be far away.Two-shift pumpingThe new mixing plants currently produceapproximately 2,000 to 3,000 m 3 of concretea day yet they are still operating belowtheir maximum capacity. Presently, around50 % of the concrete production is placedby their own truck-mounted concretepumps. The fleet of pumps comprises twoBSF 36.16H and four BSF 42.16H. Thetruck-mounted concrete pumps are operatedby two drivers who alternate betweenshifts in a similar way to their counterpartsin most of the other pumpingservices in the UAE.27Khaled Ahmed Abu Shaeerah and Najeeb M. Ashour (right)in front of a map showing the future island world of PalmJumeirahAUSTRIAN ARABIAN is currently highlyinvolved in the construction projects onPalm Jumeirah, e.g. in the concreting of themotorway bridges linking the trunk of thepalm tree to the mainland. Moreover,AUSTRIAN ARABIAN is delivering andpumping greater volumes of concrete onsix other office and apartment towers. Thecompany plans to purchase two stationarypumps and stationary booms for each highrisepumping site in the near future. SinceSeptember <strong>2005</strong> the company belongs tothe ARABTECH group.Demand for customer training on siteNajeeb M. Ashour, Chief Technical Officerand Deputy General Manager for AUSTR-IAN ARABIAN in Dubai, places considerablevalue on the qualifications of hisemployees, especially of the concrete pumpdrivers who may not yet be responsible forvaluable machines but assume a great dealof responsibility on the construction siteswhen operating the pumps and placingbooms. “We are pleased to have ouremployees travel to Germany for training,but we would much prefer it if <strong>Putzmeister</strong>could carry out the training here on site,”remarks Najeeb M.Ashour. This is becauseAUSTRIAN ARABIAN cannot cease deliveryoperations on the construction sites.There is never any talk of a “winter break”or an interruption in work due to periods ofpoor weather here in the UAE. At the PMAcademy, Najeeb M. Ashour managed towin support for his proposal of customertraining in the country itself: two-daycourses covering the topics of engineering,controls and safety in concrete pumpingand training on how to operate stationarypumps are expected to be offered in theUAE from mid-November with the cooperationof PM agency, GERMAN GULF.The large construction sites on Palm Jumeirah, whichAUSTRIAN ARABIAN supplies with concrete and on whichthe company uses its concrete pumps, also include the sliproads onto and exits from the feeder road from the mainlandNajeeb M. Ashour in front of one of the new AUSTRIANARABIAN motorway concrete pumps30 31Modern mixing facilities even for challenging concrete mixture breakdowns11PM 3723 GB

RefurbishmentNot as easy as you think –Diamant Mühle Hamburg refurbishmentSometimes its not all that easy to deliverconcrete to where it is needed. For therefurbishment of the nearly 70 year oldDiamant mill in Hamburg-Wilhelmsburg,the concrete first had to cover a distanceof about 110 m, for example, before arrivingat the sliding formwork. This was areal challenge for the team from TBGPumpendienst Nord GmbH from BadOldesloe, which relied on a <strong>Putzmeister</strong>SANIMA concrete pump and a highpressure delivery line.As part of the refurbishment of theDiamant mill, the 15 silos were concretedinside the building between February andSeptember <strong>2005</strong>. For each job, the slidingformworks in three silo cells were eachcontinuously fed with concrete for approximately80 to 90 hours. For each of the fiveconstruction sections in total, approximately300 m 3 of concrete was used. The relativelylong delivery distance and the tighttime frame, which was prescribed by thestroke speed of the sliding structure, madeparticular demands on the concrete. On theone hand, the material had to be easilypumpable, and on the other hand, it had toset quickly. As the concreting work wascarried out both in winter and in the warmsummer months, the concrete supplierROBA also adapted the concrete mixture tothe season.For easier feeding from truck mixers, the 20 m SANIMA boom is slightly raised. At this refurbishment site, the concrete isdelivered by a riser connected to the hopper (Photo: TBG Pumpendienst Nord)The mill silos were refurbished under themanagement of the construction companyWASSMANN + SÖHNE, Burgdorf.Completion is planned for the end ofDecember <strong>2005</strong>.33SANIMA delivers direct to the riserAt this construction site, the distance to becovered by the concrete before it reachesthe sliding formwork is not run of the mill.This is because the total length of all threelines to be fed with concrete was 230 m.The concrete pump, a <strong>Putzmeister</strong> SANI-MA 20.09 S, therefore not only used thedelivery line on the boom, but also pumpedthe ready-mixed concrete directly from thehopper to a connected riser. "We specificallyadapted this delivery line", said ThomasGöllner, managing director of TBGPumpendienst Nord GmbH, "for this propertyand mounted it on the exterior wallsof the silo building to be refurbished."32The vertical delivery line was carefully mounted on the wall(Photo: TBG Pumpendienst Nord)usually already fully equipped with theseadditional hoses and pipelines in specialmagazines. Several variants can be selectedin the stowage compartments, for example,TBG-Betonpumpendienst Nord's SANIMAhas up to 150 m of DN 65 hose on board.A further typical use is illustrated by therefurbishment works at the HamburgDiamant mill.Here, TBG Betonpumpendienst Nord benefitsfrom the characteristic advantages ofSANIMA. For example, the compact truckmountedconcrete pump contents itselfwith a minimum support extent of just3.9 m to the front and a support extent of2.3 m to the rear, meaning it remains withinthe vehicle dimensions. In addition, themachine has an efficient pump aggregate,which is designed for a concrete pressureRefurbishmentof up to 112 bar (maximum/theoretical).The SANIMA is therefore also equippedfor larger delivery distances.125 mm delivery line reduced to 65 mmThe connected delivery line is a <strong>Putzmeister</strong>ZX high pressure line, which can withstanda concrete pressure of 250 bar. The concretewas initially pumped 30 m high on the externalwall and then delivered approximately30 to 40 m to the silo roof. At the endof the now horizontal line, TBG employeeshad fitted a flexible delivery hose, whichwas manually switched to one of the threedownpipes leading to the silo cells (lengthapproximately 30 m each), according torequirements. Over the entire distance, thecross section of the delivery line was reducedfrom DN 125 to just DN 65. Theriser could easily be closed via a mechanicalguillotine in the pipeline at ground level.Thomas Göllner said, "This multiple taperingof the line diameter was a particularchallenge for us, as there was a risk of concretejams especially at the tapering points,and this was to be avoided at all costs in aline of this length!"The construction process required closecooperation by all those involved. For withineach construction section, all processeshad to smoothly mesh within a definedperiod of time. For TBG PumpendienstNord, this construction site is also anexample of how specialists can collaborateto successfully solve a technicallychallenging task.We would like to thank TBGBetonpumpendienst Nord and HeidelbergCement for their support.35 363412PM 3723 GBThe SANIMA 20.09 S allows extremelyflexible work, especially in refurbishmentprojects. The machine, built on a 2-axischassis, has a 20 m high placing boom withthree arm segments in a "Z" fold, whoseworking range is often sufficient in smallerconstruction sites. If the use of a largertruck-mounted concrete pump is requiredbut not possible due to the limited footprint,the 20 m SANIMA boom can also beused as a pipe bridge and the missing reachis compensated for with connected pipelinesor delivery hoses. The SANIMA isThis SANIMA 20.09 S has a 150 m delivery hose(DN 65) on boardThe ZX high pressure line is supported with timber blocks in the area of the guillotine(Photo: TBG Pumpendienst Nord)13PM 3723 GB

TechnologyFlexible 20 m "quad" – Universaltruck-mounted concrete pump withan unfolding height of just 3.9 mWith its new M 20-4 ZR model,<strong>Putzmeister</strong> AG has extended its range ofcompact truck-mounted concrete pumpswhich can be used even in the narrowestof spaces. What is particularly noticeableabout the machine is the boom which isfolded four times according to the "Z rolland fold" principle. Previously, this boomfolding type was only used on largertruck-mounted concrete pumps, e.g. forthe type M 24-4 ZR.It is easy to tell which concreting tasks thenew M 20-4 "Z roll and fold" was designedfor, with its boom folding principle andlow truck height. Primarily, it is intendedfor construction sites which could not previouslybe operated with standard truckmountedconcrete pumps. For example,narrow back yards in residential andindustrial areas as well as rooms that arelower than 4 m high. The sites in questionalso include construction and refurbishmentprojects in low buildings, tunnels or underpasses.Of course, normal constructionsites can also be operated with the foldingboom. For in concreting work in high construction,the 20 m boom is excellently suitableas a pipe bridge which – practicallywithout any loss in vertical reach – cansnake horizontally up to the 6th storey(usual floor height approximately 2.7 m)and be fed through windows or other opening,even the smallest of brickwork openings.The unfolding height of the new "quad"M 20 ZR is just 3.9 m. In addition to thespecially developed placing boom, thenewly designed base structure also takesinto account the latest findings fromweight-optimised steel construction. With afront support extent of just 3.2 m (rear withinthe vehicle width of 2.5 m), the compacttruck-mounted concrete pump can be supportedand unfolded in even the narrowestof passageways. In short – the space requiredto support the M 20-4 is not greater thanthe area that the machine takes up when thedriver's door is open.38"Quintuplet" adapts itselfA large boom pump with a particularly flexibleplacing boom was required in the carcassof the new EL CORTES INGLESshopping centre in Spanish Castellón. Awide and deep bottom plate with five basementfloors also had to be concreted, inaddition to the long underground parkingaccess and the spacious floor areas. Due tothe narrow space conditions around the OldTown, the position for setting up themachine had to be considered in greatdetail. The contract for placing the concretewas awarded to the GRUPO TELEBOM-BEO pump service provider, which used anew <strong>Putzmeister</strong> BSF 52.16 H for manyweeks at this construction site.Building constructionOur photo shows the machine during concreteplacement on the fifth storey aftermachine operator Alfredo Muñoz had integrated100 m 3 of concrete in the undergroundparking area of the future shoppingcentre a few hours previously. It is easy tosee how the boom of the M 52 "quintuplet"can adapt to the building structure withoutwasting any horizontal reach: first, the "A"and "B" arms are used to reach the requiredbuilding height. Then the length of arms"C", "D" and "E" is available as a horizontalworking range.40372,5 m3,2 mOur illustration clearly shows the narrow conditionsunder which the M 20-4 placing boom can be used(passageways, back yards, etc.).The extremely flexible concrete boom hasa 125 mm delivery line as standard, in aparticularly hard-wearing, 2-layer design.The core pump recommended by<strong>Putzmeister</strong> is an aggregate with a 1,400 mmstroke and 230 mm delivery cylinder Ø,which is designed for delivery rates of upto 90 m 3 /h or pump pressure up to 78 bar.Delivery will begin in spring 2006.The short wheelbase of just 4.5 m ensuresan extremely small turning circle. With apermissible gross weight of less than18 tons for the 2-axis chassis and an actualtare weight of approximately 15 tons(depending on the vehicle), the M 20-4also has significant weight reserves. Thisenables the small "quad" to carry additionalhoses and pipes, meaning that the workingrange of the machine is significantlyextended.39Horizontal reach 16.1 mVertical reach 19.5 mUnfolding height3.9 m14PM 3723 GB15PM 3723 GB

Large construction site42 43Numerous concrete pumpsat Germany's largestconstruction siteSince September 2004, the new StuttgartTrade Fair Centre has been under constructionat spellbinding speed, south ofthe regional capital of Baden-Württembergbetween the A8 motorway, the B 27 mainroad and the airport. Several concretepump service providers use their machineshere almost every day. In order to ensurethat concrete placement proceeds assmoothly as possible, the use of the manyconcrete pumps is scheduled centrally.motorway with direct access roads andStuttgart International Airport, which iswithin sight of the complex.The contract for construction of the tradefair halls, the congress centre and theunderground car park was awarded to theRohbau Landesmesse consortium, consistingof MAX BÖGL and LEONHARDWEISS. The two partners have also joinedforces to create a civil engineering consortium,which will construct two bypass tunnels– one near the airport and one on thenorth side of the A8 – as well as a bridge.The parking decks of the new StuttgartTrade Fair Centre stretch across the A8motorway – here is a model view(Fig.: Projektgesellschaft Neue Messe)By its opening in spring 2007, seven standardhalls with an exhibition area of10,000 m 2 each, a 25,000 m 2 tall building(headroom of 14 to 24 m), an internationalcongress centre and a generously proportionedconvention centre will be constructedhere on a total area of 83 hectares.Optimal transport connections will beensured by a planned ICE long distanceand regional train station, an undergroundcar park beneath the convention centre, thenew multi-storey car park over the A8Another consortium consisting of WAYSS& FREYTAG INGENIEURBAU,BARESEL and DONGES STAHLBAU,has been awarded the contract for completionof the new multi-storey car park,which, at a length of 440 m, spans acrossthe A8 motorway and a planned newstretch of ICE track. The total investmentfor the new Stuttgart Trade Fair Centre isestimated at EUR 806 million. The projectis currently considered to be Germany'sbiggest construction site.4144A <strong>Putzmeister</strong> M 52-5 large boom pump during concreting of the foundations16PM 3723 GBPhoto: AOP aerial photoUntil recently, the fields on which the new trade fair premises are now being constructed,were intensively farmed for pointed cabbage – a regional speciality4517PM 3723 GB

Large construction site46Up to 1,500 workers are employed on thevast site. In peak times, 60 cranes lift thevarious loads to the different sections. In aseparate production facility, prefabricatedsteel parts are supplied, and the necessarywelding and anticorrosion work is carriedout on site.Two concrete pump centres ensuresmooth placement of 270,000 m 3 ofconcreteIn order to guarantee self-supply with concrete,two mixers have been set up on thepremises. A MAX BÖGL owned systemdelivers the Rohbau consortium withapproximately 250,000 m 3 of concrete,while the concrete produced by the othermixer is required for the construction ofthe multi-storey car park (approximately20,000 m 3 ) and also covers the peaks indemand from the Rohbau consortium. Themixers also produce self-compressing concretes,in addition to standard concrete withstrength class C40/50.construction of the interior, the exposedconcrete, with its natural surface structure,plays an important role and must be pumpedwithout interruption. To do this, BRM usesall sizes of truck-mounted concrete pumps– from a refurbishing mobile through to alarge boom pump. TB Göppingen or BPSchwaben's machines are also scheduled.For the concrete work around the multistoreycar park, pump service providerSAUSSELE (Besigheim), which belongs toCEMEX, controls the use of concretepumps. Here too, it is usually the maintainedmachines from their own fleet that areset up on both sides of the motorway. Withincreasing completion of the interior of thecar park levels, the flexible "low buildingmasters" with 24 m booms with four foldsare most in demand. Other concrete pumpservice providers, such as UNION-BETON(Ludwigsburg) and GODEL-BETON(Stuttgart) also provide their machines asrequired.A PM M 36 truck-mounted concrete pump fillinga wall formwork48According to information from projectmanager Dipl.Ing. Michael Frey, the coordinationwith the central pump scheduling takesplace fairly smoothly, taking into considerationthe large concrete volumes and thenumber of contract sections. He considersthe fact that his consortium only has to coordinatewith one concrete pump schedule asa great advantage: "Of our ten foremen, eachone works with his people on a separate constructionsection.Often they all need concrete in the afternoon.Central scheduling is therefore very helpfulif our concrete mixer is constantly fullyloaded and we want to use the pumps withthe required boom reach at the same time atthe individual sections."Project manager Dipl.Ing. Michael Frey49The concrete pump scheduling for theMAX BÖGL and LEONHARD WEISSconstruction sections is carried out byBetonpumpendienst Rhein-Main (BRM),Lorsch. The range of concrete work is considerable:long strip foundations, powerfulbottom plates, floors, girders and circularsupports, external walls and internalpartitions, etc. Above all, in the47This M 36 used by the concrete pump service providerBRM is today encountered on several sections of thevast trade fair construction site50BRM operatorWerner Mann. Hehas been operating51concrete pumps for13 yearsOur picture shows one of BP Schwaben's BSF 52.16 Hpumps on field 2 during the placement of 280 m 3 ofconcrete. As soon as the bottom plate is completely concreted,the machine is moved by a few hundred metres,in order to pump 400 m 3 of concrete into a ceiling formwork.18PM 3723 GBA BSF 28.16 H with refurbishment equipment19PM 3723 GB

BackgroundHigh quality requirements even in theconstruction of model concrete pumps54Background55These are gifts with which you can giveparticular pleasure to business partners.Some people have even collected theirexhibits, sometimes over the course ofmany years, with great commitment –above all of a financial nature. We aretalking about miniature constructionmachines, which are produced to scale byhighly specialised manufacturers, such asCONRAD GmbH (Kalchreuth).<strong>Putzmeister</strong> too has been buying the differentmodels of its truck-mounted concretepumps since the 70s, and also the TELE-BELT telescopic deliverer, as models producedto a scale of 1:50 from the Franconianspecialist. A larger model scale of 1:35 hasbeen chosen for the PM plastering machinesand floor screed conveyors – let's notforget the machines are actually significantlysmaller in real life. The decision to ordera model of a concrete pump with the newplacing boom, for example, must be wellthought out. For, in addition to the laterunit costs, the customer often also has tocover the costs for the handmade model,that is, for the prototype, as well as for theconstruction of the mould.Before the new models can be produced,an accurate manually produced specimenmust be created. To do this, the dimensionsof the original are converted to scale, the52required material strengths are calculatedand the mobility – e.g. the composition ofa multi-part concrete boom – is simulated.The handmade model is also used as apattern for the construction of the modeland for the subsequent mould construction.Modern CAD/CAM computer systems andCNC milling machines play an importantrole in conveying the fine contours.As with the "real" construction machines,CONRAD uses metal (zinc) and highqualityplastic for its models. The relativelyheavy zinc is not only easy to handle inliquid form, but its weight also gives thefinished model part of the "valency" and"mass" of the actual original. The plasticand the zinc are both pressed in injectionmoulds in which the respective componentsare given their later, often filigreestructure. Several components are held byone mould carrier. The zinc is pressed at apressure of up to 150 t/cm 2 .After the mould carriers are automaticallyejected from the injection moulding machines,CONRAD employees carefully checkthe individual parts. The edges are filed bymachine, but the grinding and polishing isstill often manual work. The entire productionprocess is organised to the last detail.As with the original, the visual impressionof the product also plays an important rolein model construction. This includes asmooth, notch-free surface as well as carefulpainting. At CONRAD, the same undercoatand topcoat paint is used as in theautomotive industry. The paint is applied inup to six stages. As the colour tone of thecomponents consisting of different materialsmust be the same, different paint compositionsare used for colouration of theplastic components and the cast zinc parts.A CONRAD employee operating the injection mouldingmachine53Even the latest PM models are producedwith attention to detail.The picture shows the SIKA-PM 500 shotcrete deviceas well as the high pressure BSA 14000 HP-Dconcrete pumpCONRAD was founded in 1956 and beganproducing faithful model vehicles in 1971.Today, the company presents itself as theleading manufacturer of model vehicles,with modern prototype and mould construction,a pressure casting foundry, plasticinjection moulding, an environmentallyfriendly painting system and a departmentfor screen printing. Due to the good collaborationthey have experienced over decades,<strong>Putzmeister</strong> AG has also arranged to haveits new models, such as the BSA 14000 HPconcrete pump and the SIKA-PM 500shotcrete device manufactured byCONRAD GmbH.5657Mould carriers with parts of the stationary pump modelThe zinc raw material is delivered to model builderCONRAD in barsThe two halves of an injection mould for the BSA model20PM 3723 GB21PM 3723 GB

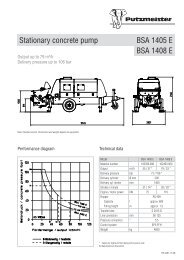

Special concreteThe ZX delivery line in the lattice tower of thecrane runs to the sliding formworkNew platinum minein South Africa:concrete placement on109 m high pit frame5860Platinum and its costly miningPlatinum is currently almost twice as expensiveas gold, and significantly harder.World-wide, only approximately 200 tonsof this precious metal are mined each year,with 90 % of the production stemmingfrom South African mines. Platinum isrequired, for example, for the productionof catalytic converters in the automotiveindustry, in dental medicine, in space traveland for the production of jewellery. Toacquire 15 grams of pure platinum, up tofive tons of stone must be exploded, conveyed,pulverised and chemically treated.The metal is prepared above ground inhigh security areas. The platinum discoverysites around the Rustenburg regionwere mined in a strip of approximately400 km. Here, 27,000 miners work underthe hardest of conditions at depths ofapproximately 2,000 m. With an air humidityof 90 %, there are temperatures at thisdepth of up to 50 °C. The platinum reserveswere discovered in 1924 by the Germangeologist Hans Merensky. The land rightsin Rustenburg belong to the Bafokengclan, to which the IMPALA PLATINUMgroup assigns 5 % of its profit each yearas payment for rights of use.In Rustenburg in South Africa, theIMPALA PLATINUM LTD mining companyis investing significant sums ofmoney in the mining of the precious metalplatinum. In the meantime, work is beingcarried out on the completion of the 16thshaft. Already before commissioning,<strong>Putzmeister</strong> pumps were used here,although not for pumping residues fromthe ore dressing (tailings), but for highriseconcrete pumping.In addition to constructing the shaft andconnecting a new mining field to the existingmining fields, the tapping of a newmine also includes the installation of a pitframe. At its tip, the pit rope, to which thehaulage skips for bringing up the minedmaterial and the baskets for transportingthe miners are attached, runs over a largepulley. In order to move the largest loadspossible, or to achieve short circulationtimes, the pit frame must be of a certainheight. At the 16th pit of IMPALA inRustenburg, the tower is certainly not toosmall: with a base of 21 m x 20 m and apulley at the record height of 109 m, thenew pit is designed for extraordinary conveyingcapacities.A sliding formwork adapts to differentwall thicknessesThe work on the pit frame with severalintegrated concrete decks began with thepit brow at a depth of approximately 25 m.The main contractor assigned with theconstruction work is RENNIKS CON-STRUCTION. The project, costing around80 million rand (approximately EUR 10million), also includes the construction ofthe main ventilation shaft, several accesstunnels, the foundation of the conveyingsystem and various digging works.Completion is planned for May 2006.The walls of the pit frame, which arebetween 0.95 m and 0.55 m thick, wereconstructed using the sliding formworkprocedure. Here, the formwork adapted22PM 3723 GBTruck mixers load the BSA 1408 E with a special type of concrete59In total, approximately 21,000 m 3 of concrete are processedat the pit frame62The PM gate valves are activated via a hydraulic circuitin the stationary pump61flexibly to the wall diameter which becomesthinner as you move upwards. The contractfor concrete delivery was awarded to thespecialists from MURRAY & ROBERTSCONSTRUCTION, who, incidentally, havebeen working with <strong>Putzmeister</strong> pumps formany years.In total, 7,000 m 3 of concrete was requiredto construct the carcass of the pit frame.The concrete used had a specially developedmixture breakdown. It contained,amongst other things, aggregate with amaximum particle size of 19 mm (of which50 % was slag), drift sand, stone dust andvarious concrete additives. The furtherdetails of the concrete composition areconsidered to be confidential. In other constructionmeasures within the project, afurther 14,000 m 3 of concrete was placed.The "chief operator" has full control of his <strong>Putzmeister</strong>stationary pump. On the left you can see the cableremote control of the BSA 1408 E63BSA and rotary distributorswork as a teamThe free-pumping material was deliveredby MURRAY & ROBERTS with a<strong>Putzmeister</strong> BSA 1408 E via a ZX highpressure line, which was mounted on atower crane. With a hydraulically activatedgate valve, the concrete flow in the pipelinecould be interrupted, for example for cleaningoperations on the stationary pump.A second BSA was kept ready as a standbypump. The crane was set up about threemetres from the carcass and mounted withcross-beams in the continuously risingstructure. The upper end of the riser wasconnected with a flexible hose (DN 125),so that a connection to the RV 10 rotarydistributor on the sliding formwork couldbe established at any time in the 90 ° deliveryline bend. Incidentally, this too was adevice manufactured by the <strong>Putzmeister</strong>subsidiary in South Africa. In the interestof the most unrestricted slewing circlepossible, the construction company elevatedthe four support legs of the deck distributorby approximately 5 m.Service technicians available at all timesDuring the carcass construction phase,employees of <strong>Putzmeister</strong> South Africawere on site at least once a week. Theytrained the concrete pump operators, gavetips on cleaning and maintenance of theBSA and clarified any service questions.In addition, the PMSA emergency servicewas also available 24/7 via a hotline.A service technician could have been onsite within 2 hours, if required.As the construction progressed, additionalpipe sections were used between the riserand the delivery hose. On average, the pitframe grew by 4.5 m each day, with thebest daily performance being 6 m. At109 m, the BSA 1408-E reached its highestpump height on the new IMPALA pit.23PM 3723 GB

Special concreteLarge boom concrete pumps inject"Bügelbauten" bookend buildingsWith the completion of the two 46 m talloffice towers, the last construction sectionof the new Berlin main train stationbegan at the end of July <strong>2005</strong>. The imposingbuilding is being constructed on thesite of the former Lehrter train stationand, after completion, will be used as thecentral terminal for north/south andeast/west rail transport in the Germancapital. According to forecasts, 300,000passengers and visitors are expected at theLehrter train station each day.The pump service provider LICHTNERused three <strong>Putzmeister</strong> concrete pumps toinject the complicated floor structure ofsteel sections with a specially developedconcrete, as well as to concrete the floors.68 69Berlin's first main train stationAs in London and Paris, Berlin neverhad a central main train station in thepast. Due to the star-shaped railwaynetwork, the railway lines ended at theedge of the capital city. At the end ofthe 19th century, a suburban railwayline connected the city's most importantlong-distance train stations.The old Lehrter train station, opened in1871, was severely damaged in theSecond World War, and the ruins of theformer building were blasted at the endof the 50s. Thereafter, the Berlin suburbanrailway used the site as a stoppingpoint. After the fall of the Berlinwall, intensive work went into plansfor a central traffic node for theGerman capital city. In 1998, work onthe new train station began.At the end of May 2006, shortly beforethe Football World Cup, the Lehrtertrain station is to be officially openedas "Europe's most modern train terminal"– according to DEUTSCHEBAHN AG.The aboveground part of the new Berlinmain train station (east/west direction) hasfour platforms for long-distance and regionaltrains and two platforms for suburbanrailway traffic, 10 m above street level. Forthe north/south connection, eight platformsfor long-distance and regional trains aswell as two for the underground line U5will be constructed 15 m below ground.A huge glass roof with a length of 321 m,which is installed above the east/westwing, will act as protection against badweather and will allow daylight to reacheven the deeper floors.The critical section of the project is thecompletion of the bookend buildings. Theseare two 46 m tall office buildings which, ata length of 87 m, straddle the east-west linelike bridges at the intersection of the railway.The two twelve storey buildings wereinitially constructed as four vertical towerhalves, which were tilted by 90° in summer<strong>2005</strong> and welded. This procedure, which isnot carried out every day, was chosen to ensurethat the railway traffic flowing beneaththe buildings did not have to experiencedisruption caused by a long constructionperiod.The carcass construction work for the solidstructure of the bookend buildings wascarried out by WAYSS & FREYTAGINGENIEURBAU AG.Highly effective deflocculant helps theconcrete spread into "dead angles"The four bookend buildings consist ofnumerous steel pipe sections which aredesigned as loadbearing composite constructions.26PM 3723 GBLowering of the bookend buildings over the east/west line of the Lehrter train station (Photo: DB AG/Reiche)Even in the narrowest of spaces, the two<strong>Putzmeister</strong> M 42 and M 52 can be set up bythe concrete pump service provider LICHTNER– as shown here for concreting the floors67Amongst other things, the pylons, theexternal and internal supports of the basesof the bookend buildings and the latticegirders of the four 1,250 ton bookend halveswith their numerous upper, middle andlower flanges were injected with concrete.The contract for this work was awarded toLICHTNER pump service provider fromVelten, which, over a period of months,used its <strong>Putzmeister</strong> truck-mountedBSF 36.16 HLS, BSF 42.16 H andBSF 52.16 H concrete pumps for the work.The steel sections contain a very denselyset reinforcement and, up to a height of10 m, are injected with a specially developedconcrete with strength class C45/55 inone operation. The mixture breakdownincludes an increased fines content and ahighly effective plasticising admixturebased on polycarboxylatether (PCE), whichdisplays an even higher deflocculationeffect compared with the familiar superdeflocculants. As the pumped concrete containspractically no more air particles, andhas a very free-flowing consistency (F5 toF6), additional shaking is not necessary.Injection through 150 m long 65 mmdelivery hoseAt the start of the injection work, the boomlength of the BSF 36.16 HLS was stillsufficient. As the construction progressed,however, LICHTNER started to use itsconcrete pumps with 42 and 52 metrevertical reach. In order to also be able toUp to three concrete pumps simultaneously inject the numeroussteel sections of the bookend buildings. Picture shows M 36.reach the farther removed filler pipes, atapering, which reduced the line diameterto 65 mm, was connected to the machine'sboom tip instead of an end hose. Theconnection of up to 150 metres of hosemeant a significantly increased workingrange could be achieved. As expected, thehydraulic pressure of the pumps increased,but remained within a reasonable limit.Filler pipes situated beneath the steel sectionsfill them with quantities of 5 to 6 m 3 .The slow ascent of the concrete in the constructionalelement discharges the availableair upwards. The filler pipes in the injectedsteel sections are closed with guillotinesand concrete is prevented from escaping bycutting the line. Injection of the bookendbuildings started in April <strong>2005</strong> and completionis planned for the end of <strong>2005</strong>.In addition to injecting the steel sectionswith special concrete, the two LICHTNERlarge boom pumps BSF 42.16 H andBSF 52.16 H are also used for concretingthe floors. Their boom length means theycan also reach higher levels of the bookendbuildings. To do this, the large boompumps need a C 40/50 concrete with amaximum particle size of 16 mm, and theindividual sections each hold approximately120 m 3 . For this work too, the pipe at theboom tip of the truck-mounted concretepump was reduced to 65 mm diameterthrough the addition of a tapering and aflexible hose with a length of up to 30 mwas connected.The floors are concreted with the boom tip extendedand with a 65 mm delivery hose attachedGuillotines are used to close the steel sections afterinjection707127PM 3723 GB

ApplicationConcretingon waterImprint:Publisher<strong>Putzmeister</strong> AGMax-Eyth-Str. 10D-72631 AichtalTel.+49 (71 27) 599-0Fax 599-520■ Editor:Jürgen Kronenberg■ Design:Friedrich Pippich<strong>Putzmeister</strong> AG, Max-Eyth-Str. 10, D-72631 AichtalPSdg, Deutsche Post AG, Entgelt bezahlt, E 60458This picture shows how you can set up anefficient concreting unit for underwaterconcrete work in the smallest of spaces.The six machines consisted of four truckmixer swap bodies with independent powerunit, a stationary concrete pump and astationary <strong>Putzmeister</strong> MX 24 boom on atubular column. Our picture does not revealthe location of the stationary pump, whichis between the four truck mixer swapbodies and was fed via chutes from themixers. The concrete was delivered via ashort pump line to the stationary boom(here still the older "triplet" version withroll-and-fold system). To fill the mixerdrums, each with a capacity of 7 m 3 , thepontoon was pulled to the "short line" bytwo small tugs and towed to the harbourquay. There, the "correct" truck mixerswere waiting to handover the ready-mixedconcrete.72Your fax for further information■ Would you like more information on certain topics in this edition of <strong>Putzmeister</strong> Post?If so, just copy this page, make a cross next to the topics you are interested in and faxthe form to us. We will then send you detailed information immediately.❏ Delivery line systems ............................................................................PM 2300❏ Stationary concrete pumps ....................................................................BP 2632❏ Economic concrete distribution with stationary booms..........................MT 2059❏ TELEBELT Telescopic belt conveyor TB 105 ..........................................TB 2409❏ DYNAJET-High Pressure Cleaners ......................................................MM 3464❏ Truck-mounted concrete pump M 20-4 „Z“............................................BP 3697❏ Truck-mounted concrete pump M 52-5 „Multi-Z“ ................................MT 3231❏ Truck-mounted concrete pump M 36-4 „Z“............................................BP 3180❏ Truck-mounted concrete pump M 28-4 ................................................MT 2634❏ Truck-mounted concrete pump SANIMA 20.09 S ..................................BP 2765❏ Truck-mounted concrete pump M 42-4 „R“ ..........................................MT 2391Name ........................................................................................................Company ..................................................................................................Position ....................................................................................................Street ........................................................................................................Post code/City ..........................................................................................Tel. no. ......................................................................................................E-Mail........................................................................................................<strong>Putzmeister</strong> AGMax-Eyth-Str. 10 · D-72631 AichtalP.O.Box 21 52 · D-72629 AichtalTel. +49 (71 27) 599-0Fax +49 (71 27) 599-520Internet: http://www.putzmeister.deE-mail: pmw@pmw.dePM 3723 GBAll rights reserved. Subject to technical amendments without notice. The illustrations in some cases show special-purpose machine designs and snapshots of sitepractice which do not always comply with the regulations determined by professional bodies. © <strong>2005</strong> by <strong>Putzmeister</strong> Printed in Germany (3.50512RR)

![Data sheet BSA 1005 E (TB 1186) [.pdf; 278.88 kb]](https://img.yumpu.com/40181054/1/184x260/data-sheet-bsa-1005-e-tb-1186-pdf-27888-kb.jpg?quality=85)

![(BP 3531) [.pdf; 221.30 kb] - Putzmeister Concrete Machines Pvt. Ltd.](https://img.yumpu.com/35322592/1/184x260/bp-3531-pdf-22130-kb-putzmeister-concrete-machines-pvt-ltd.jpg?quality=85)

![Data sheet M 70-5 (BP 4311) [.PDF (kb383); 721.22 kb] - Putzmeister](https://img.yumpu.com/29333530/1/184x260/data-sheet-m-70-5-bp-4311-pdf-kb383-72122-kb-putzmeister.jpg?quality=85)