cotton - Greenmount Press

cotton - Greenmount Press

cotton - Greenmount Press

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Ginning & fibre quality<br />

Series supported by ECOM Commodities<br />

Recycled textile fibre as a<br />

reinforcement for composites<br />

■ Dr Menghe Miao 1 , Samuel Ello-Ekombo 1 and Dr Stuart Gordon 1<br />

ABOUT one million tonnes of textile fibre waste is<br />

generated each year in Australia, of which about<br />

900,000 tonnes goes to landfill. As 35–40 per cent of<br />

textile products are <strong>cotton</strong>, the <strong>cotton</strong> pipeline has a significant<br />

environmental responsibility to fulfil.<br />

Pre-consumer textile waste is manufacturing waste generated<br />

by processing fibres (be they natural or synthetic fibres) and<br />

the production of finished yarns and textiles, technical textiles,<br />

nonwovens, garments and footwear, including off-cuts,<br />

selvages, shearings, rejected materials and B-grade garments.<br />

Post-consumer textile waste consists of any type of garments or<br />

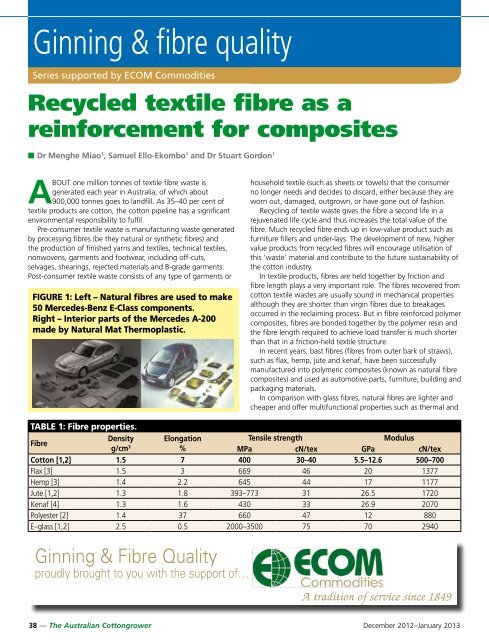

FIGuRE 1: Left – Natural fibres are used to make<br />

50 Mercedes-Benz E-Class components.<br />

Right – Interior parts of the Mercedes A-200<br />

made by Natural Mat Thermoplastic.<br />

household textile (such as sheets or towels) that the consumer<br />

no longer needs and decides to discard, either because they are<br />

worn out, damaged, outgrown, or have gone out of fashion.<br />

Recycling of textile waste gives the fibre a second life in a<br />

rejuvenated life cycle and thus increases the total value of the<br />

fibre. Much recycled fibre ends up in low-value product such as<br />

furniture fillers and under-lays. The development of new, higher<br />

value products from recycled fibres will encourage utilisation of<br />

this ‘waste’ material and contribute to the future sustainability of<br />

the <strong>cotton</strong> industry.<br />

In textile products, fibres are held together by friction and<br />

fibre length plays a very important role. The fibres recovered from<br />

<strong>cotton</strong> textile wastes are usually sound in mechanical properties<br />

although they are shorter than virgin fibres due to breakages<br />

occurred in the reclaiming process. But in fibre reinforced polymer<br />

composites, fibres are bonded together by the polymer resin and<br />

the fibre length required to achieve load transfer is much shorter<br />

than that in a friction-held textile structure.<br />

In recent years, bast fibres (fibres from outer bark of straws),<br />

such as flax, hemp, jute and kenaf, have been successfully<br />

manufactured into polymeric composites (known as natural fibre<br />

composites) and used as automotive parts, furniture, building and<br />

packaging materials.<br />

In comparison with glass fibres, natural fibres are lighter and<br />

cheaper and offer multifunctional properties such as thermal and<br />

TABLE 1: Fibre properties.<br />

Fibre<br />

Density Elongation<br />

Tensile strength<br />

Modulus<br />

g/cm 3<br />

%<br />

MPa<br />

cN/tex<br />

GPa<br />

cN/tex<br />

Cotton [1,2] 1.5 7 400 30–40 5.5–12.6 500–700<br />

Flax [3] 1.5 3 669 46 20 1377<br />

Hemp [3] 1.4 2.2 645 44 17 1177<br />

Jute [1,2] 1.3 1.8 393–773 31 26.5 1720<br />

Kenaf [4] 1.3 1.6 430 33 26.9 2070<br />

Polyester [2] 1.4 37 660 47 12 880<br />

E–glass [1,2] 2.5 0.5 2000–3500 75 70 2940<br />

Ginning & Fibre Quality<br />

proudly brought to you with the support of…<br />

A tradition of service since 1849<br />

38 — The Australian Cottongrower December 2012–January 2013