Steel Joist Manual

Steel Joist Manual

Steel Joist Manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

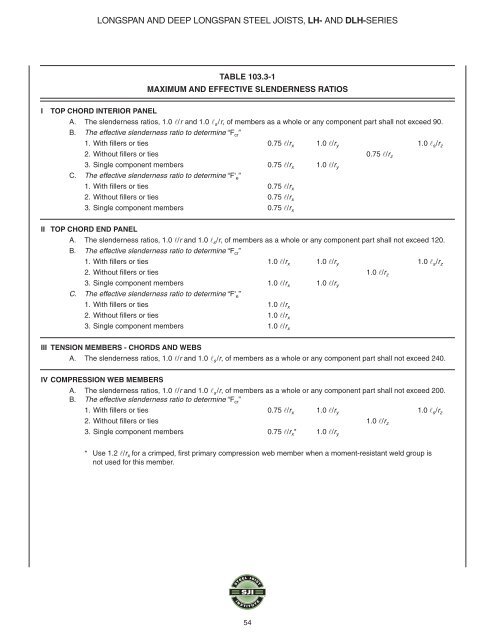

LONGSPAN AND DEEP LONGSPAN STEEL JOISTS, LH- AND DLH-SERIES<br />

TABLE 103.3-1<br />

MAXIMUM AND EFFECTIVE SLENDERNESS RATIOS<br />

I<br />

TOP CHORD INTERIOR PANEL<br />

A. The slenderness ratios, 1.0 l/r and 1.0 l s /r, of members as a whole or any component part shall not exceed 90.<br />

B. The effective slenderness ratio to determine “F cr ”<br />

1. With fillers or ties 0.75 l/r x 1.0 l/r y 1.0 l s /r z<br />

2. Without fillers or ties 0.75 l/r z<br />

3. Single component members 0.75 l/r x 1.0 l/r y<br />

C. The effective slenderness ratio to determine “F' e ”<br />

1. With fillers or ties 0.75 l/r x<br />

2. Without fillers or ties 0.75 l/r x<br />

3. Single component members 0.75 l/r x<br />

II<br />

TOP CHORD END PANEL<br />

A. The slenderness ratios, 1.0 l/r and 1.0 l s /r, of members as a whole or any component part shall not exceed 120.<br />

B. The effective slenderness ratio to determine “F cr ”<br />

1. With fillers or ties 1.0 l/r x 1.0 l/r y 1.0 l s /r z<br />

2. Without fillers or ties 1.0 l/r z<br />

3. Single component members 1.0 l/r x 1.0 l/r y<br />

C. The effective slenderness ratio to determine “F' e ”<br />

1. With fillers or ties 1.0 l/r x<br />

2. Without fillers or ties 1.0 l/r x<br />

3. Single component members 1.0 l/r x<br />

III TENSION MEMBERS - CHORDS AND WEBS<br />

A. The slenderness ratios, 1.0 l/r and 1.0 l s /r, of members as a whole or any component part shall not exceed 240.<br />

IV COMPRESSION WEB MEMBERS<br />

A. The slenderness ratios, 1.0 l/r and 1.0 l s /r, of members as a whole or any component part shall not exceed 200.<br />

B. The effective slenderness ratio to determine “F cr ”<br />

1. With fillers or ties 0.75 l/r x 1.0 l/r y 1.0 l s /r z<br />

2. Without fillers or ties 1.0 l/r z<br />

3. Single component members 0.75 l/r x * 1.0 l/r y<br />

* Use 1.2 l/r x for a crimped, first primary compression web member when a moment-resistant weld group is<br />

not used for this member.<br />

54