Steel Joist Manual

Steel Joist Manual

Steel Joist Manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

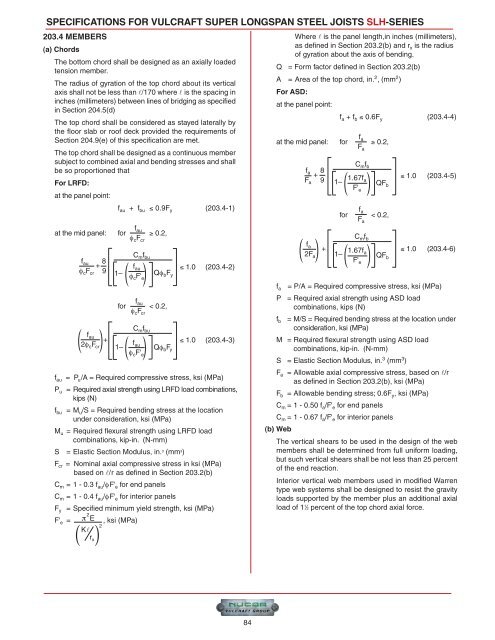

SPECIFICATIONS FOR VULCRAFT SUPER LONGSPAN STEEL JOISTS SLH-SERIES<br />

203.4 MEMBERS<br />

(a) Chords<br />

The bottom chord shall be designed as an axially loaded<br />

tension member.<br />

The radius of gyration of the top chord about its vertical<br />

axis shall not be less than l/170 where l is the spacing in<br />

inches (millimeters) between lines of bridging as specified<br />

in Section 204.5(d)<br />

The top chord shall be considered as stayed laterally by<br />

the floor slab or roof deck provided the requirements of<br />

Section 204.9(e) of this specification are met.<br />

The top chord shall be designed as a continuous member<br />

subject to combined axial and bending stresses and shall<br />

be so proportioned that<br />

For LRFD:<br />

at the panel point:<br />

f au + f bu ≤ 0.9F y (203.4-1)<br />

at the mid panel: for ≥ 0.2,<br />

φ c F cr<br />

f au<br />

P u<br />

f bu<br />

f au +<br />

8<br />

φ c F cr 9<br />

( )<br />

f au<br />

2φ c F cr<br />

+<br />

1–<br />

f au<br />

for < 0.2,<br />

φ c F cr<br />

1–<br />

≤ 1.0 (203.4-2)<br />

≤ 1.0 (203.4-3)<br />

= P u /A = Required compressive stress, ksi (MPa)<br />

= Required axial strength using LRFD load combinations,<br />

kips (N)<br />

= M u /S = Required bending stress at the location<br />

under consideration, ksi (MPa)<br />

M u = Required flexural strength using LRFD load<br />

combinations, kip-in. (N-mm)<br />

S = Elastic Section Modulus, in. 3 (mm 3 )<br />

F cr = Nominal axial compressive stress in ksi (MPa)<br />

based on l/r as defined in Section 203.2(b)<br />

C m = 1 - 0.3 f au /φF' e for end panels<br />

C m = 1 - 0.4 f au /φF' e for interior panels<br />

F y = Specified minimum yield strength, ksi (MPa)<br />

F' e = π<br />

( 2 E<br />

) , ksi (MPa)<br />

2<br />

Kl<br />

r x<br />

Where l is the panel length,in inches (millimeters),<br />

as defined in Section 203.2(b) and r x is the radius<br />

of gyration about the axis of bending.<br />

Q = Form factor defined in Section 203.2(b)<br />

A = Area of the top chord, in. 2 , (mm 2 )<br />

For ASD:<br />

at the panel point:<br />

f a + f b ≤ 0.6F y (203.4-4)<br />

at the mid panel: for ≥ 0.2,<br />

f a<br />

( )<br />

+ 8<br />

F 1.67f a 9<br />

a<br />

F' e<br />

f a<br />

F a<br />

f au<br />

( ) C<br />

( m f b<br />

f a<br />

)<br />

+ 1.67f<br />

C m f a<br />

bu<br />

2F a<br />

Qφ b F y<br />

( )<br />

f au<br />

φ c F' e<br />

C m f ( ) bu<br />

f au<br />

φ c F' e<br />

Qφ b F y<br />

f a<br />

f a<br />

F a<br />

C m f b<br />

1– QF b<br />

for < 0.2,<br />

1– QF<br />

F' b<br />

e<br />

≤ 1.0 (203.4-5)<br />

≤ 1.0 (203.4-6)<br />

= P/A = Required compressive stress, ksi (MPa)<br />

P = Required axial strength using ASD load<br />

combinations, kips (N)<br />

f b = M/S = Required bending stress at the location under<br />

consideration, ksi (MPa)<br />

M = Required flexural strength using ASD load<br />

combinations, kip-in. (N-mm)<br />

S = Elastic Section Modulus, in. 3 (mm 3 )<br />

F a = Allowable axial compressive stress, based on l/r<br />

as defined in Section 203.2(b), ksi (MPa)<br />

F b = Allowable bending stress; 0.6F y , ksi (MPa)<br />

C m = 1 - 0.50 f a /F' e for end panels<br />

C m = 1 - 0.67 f a /F' e for interior panels<br />

(b) Web<br />

The vertical shears to be used in the design of the web<br />

members shall be determined from full uniform loading,<br />

but such vertical shears shall be not less than 25 percent<br />

of the end reaction.<br />

Interior vertical web members used in modified Warren<br />

type web systems shall be designed to resist the gravity<br />

loads supported by the member plus an additional axial<br />

load of 1 1 ⁄2 percent of the top chord axial force.<br />

84