Appendix J - Peabody Energy

Appendix J - Peabody Energy

Appendix J - Peabody Energy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

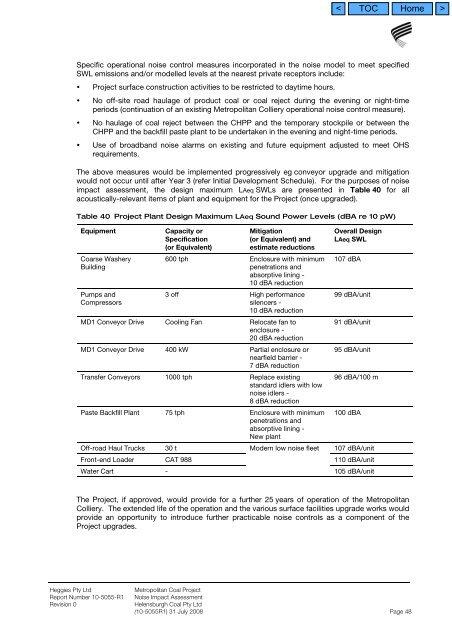

Specific operational noise control measures incorporated in the noise model to meet specified<br />

SWL emissions and/or modelled levels at the nearest private receptors include:<br />

• Project surface construction activities to be restricted to daytime hours.<br />

• No off-site road haulage of product coal or coal reject during the evening or night-time<br />

periods (continuation of an existing Metropolitan Colliery operational noise control measure).<br />

• No haulage of coal reject between the CHPP and the temporary stockpile or between the<br />

CHPP and the backfill paste plant to be undertaken in the evening and night-time periods.<br />

• Use of broadband noise alarms on existing and future equipment adjusted to meet OHS<br />

requirements.<br />

The above measures would be implemented progressively eg conveyor upgrade and mitigation<br />

would not occur until after Year 3 (refer Initial Development Schedule). For the purposes of noise<br />

impact assessment, the design maximum LAeq SWLs are presented in Table 40 for all<br />

acoustically-relevant items of plant and equipment for the Project (once upgraded).<br />

Table 40 Project Plant Design Maximum LAeq Sound Power Levels (dBA re 10 pW)<br />

Equipment<br />

Coarse Washery<br />

Building<br />

Pumps and<br />

Compressors<br />

Capacity or<br />

Specification<br />

(or Equivalent)<br />

Mitigation<br />

(or Equivalent) and<br />

estimate reductions<br />

600 tph Enclosure with minimum<br />

penetrations and<br />

absorptive lining -<br />

10 dBA reduction<br />

3 off High performance<br />

silencers -<br />

10 dBA reduction<br />

Overall Design<br />

LAeq SWL<br />

107 dBA<br />

99 dBA/unit<br />

MD1 Conveyor Drive Cooling Fan Relocate fan to<br />

91 dBA/unit<br />

enclosure -<br />

20 dBA reduction<br />

MD1 Conveyor Drive 400 kW Partial enclosure or 95 dBA/unit<br />

nearfield barrier -<br />

7 dBA reduction<br />

Transfer Conveyors 1000 tph Replace existing 96 dBA/100 m<br />

standard idlers with low<br />

noise idlers -<br />

8 dBA reduction<br />

Paste Backfill Plant 75 tph Enclosure with minimum 100 dBA<br />

penetrations and<br />

absorptive lining -<br />

New plant<br />

Off-road Haul Trucks 30 t Modern low noise fleet 107 dBA/unit<br />

Front-end Loader CAT 988 110 dBA/unit<br />

Water Cart -<br />

105 dBA/unit<br />

The Project, if approved, would provide for a further 25 years of operation of the Metropolitan<br />

Colliery. The extended life of the operation and the various surface facilities upgrade works would<br />

provide an opportunity to introduce further practicable noise controls as a component of the<br />

Project upgrades.<br />

Heggies Pty Ltd<br />

Report Number 10-5055-R1<br />

Revision 0<br />

Metropolitan Coal Project<br />

Noise Impact Assessment<br />

Helensburgh Coal Pty Ltd<br />

(10-5055R1) 31 July 2008 Page 48