Strength and Durability of a 70% Ground Granulated Blast Furnace ...

Strength and Durability of a 70% Ground Granulated Blast Furnace ...

Strength and Durability of a 70% Ground Granulated Blast Furnace ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Appendix A: Batching, Curing, <strong>and</strong> Testing Procedures<br />

Cube specimens for this study were mixed, cast, cured, <strong>and</strong> tested based on pertinent<br />

sections <strong>of</strong> the procedures set forth in ASTM C 109/C 109M-02.<br />

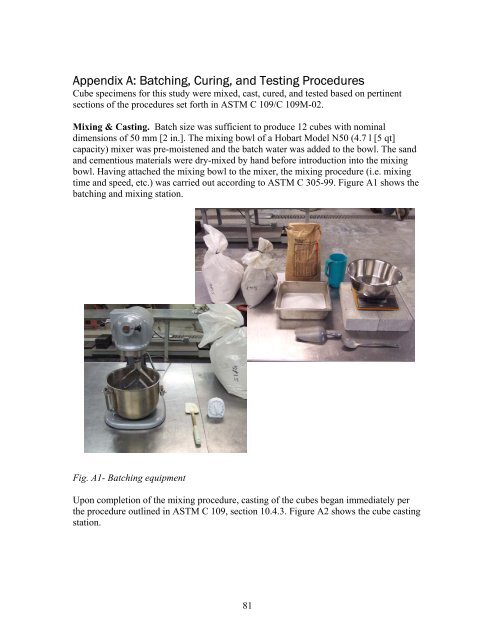

Mixing & Casting. Batch size was sufficient to produce 12 cubes with nominal<br />

dimensions <strong>of</strong> 50 mm [2 in.]. The mixing bowl <strong>of</strong> a Hobart Model N50 (4.7 l [5 qt]<br />

capacity) mixer was pre-moistened <strong>and</strong> the batch water was added to the bowl. The s<strong>and</strong><br />

<strong>and</strong> cementious materials were dry-mixed by h<strong>and</strong> before introduction into the mixing<br />

bowl. Having attached the mixing bowl to the mixer, the mixing procedure (i.e. mixing<br />

time <strong>and</strong> speed, etc.) was carried out according to ASTM C 305-99. Figure A1 shows the<br />

batching <strong>and</strong> mixing station.<br />

Fig. A1- Batching equipment<br />

Upon completion <strong>of</strong> the mixing procedure, casting <strong>of</strong> the cubes began immediately per<br />

the procedure outlined in ASTM C 109, section 10.4.3. Figure A2 shows the cube casting<br />

station.<br />

81