Training by Schneider Electric - WF Senate

Training by Schneider Electric - WF Senate

Training by Schneider Electric - WF Senate

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

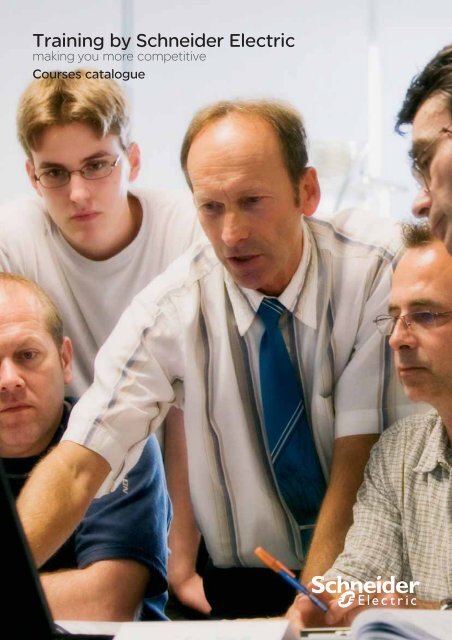

<strong>Training</strong> <strong>by</strong> <strong>Schneider</strong> <strong>Electric</strong><br />

making you more competitive<br />

Courses catalogue

<strong>Training</strong> <strong>by</strong> <strong>Schneider</strong> <strong>Electric</strong>,<br />

making you more competitive<br />

<strong>Training</strong> courses focused on your needs<br />

@ Solve specific technical problems<br />

@ Bring your new staff up to speed<br />

@ Optimise your equipment maintenance<br />

@ Acquire skills for the modernisation of your installations<br />

@ Optimise the management of your teams<br />

@ Reduce your energy bill<br />

...What about your needs<br />

Courses for all your technical and business issues<br />

<strong>Training</strong> on<br />

<strong>Schneider</strong> <strong>Electric</strong> products<br />

<strong>Schneider</strong> <strong>Electric</strong> solutions<br />

your day-to-day business issues<br />

<strong>Training</strong> Solutions throughout your installation lifecycle<br />

Dedicated training teams close to you<br />

100, 000<br />

persons trained<br />

worldwide in 2007<br />

3<br />

main types of courses:<br />

Products / Solutions / Businesses<br />

50<br />

training centres<br />

around the world<br />

Experience of international industrialists<br />

Manufacturer’s know-how<br />

Teaching expertise<br />

500<br />

in-house & external<br />

trainers<br />

2

Introduction<br />

We all face a raft of new legislative and health and safety measures in an increasingly<br />

competitive market, combined with a continual drive for cost efficiencies. You need a partner<br />

who understands your everyday pressures and provides a genuine competitive edge in your<br />

operations.<br />

We offer a flexible range of practical training courses to develop the judgement and skills of<br />

your staff, with our professional training organisation delivering a profitable investment for<br />

you.<br />

The benefits of training with <strong>Schneider</strong> <strong>Electric</strong> include:<br />

@ A highly qualified team of instructors with 200+ years experience across a range of<br />

industry sectors<br />

@ A hands-on approach which gives safe exposure to real-world situations<br />

@ A dedicated training centre which enables you to learn quickly and effectively on the<br />

types of equipment you encounter day to day<br />

@ As one of the world’s leading electrical manufacturers, <strong>Schneider</strong> <strong>Electric</strong> gives you the<br />

reassurance of expert, up to date instruction to make maximum use of your valuable time<br />

@ The potential to tailor courses to your particular needs<br />

@ The option of training at your site, to get your entire department up to speed as effectively<br />

as possible<br />

3

CONTENTS<br />

<strong>Training</strong> on <strong>Schneider</strong> <strong>Electric</strong> products<br />

@ GenieEvo switchgear - page 10<br />

@ Modicon TSX PL7 Pro software - page 18<br />

@ Ringmaster switchgear - page 11<br />

@ Sepam relays - page 12<br />

@ LV air circuit breakers - page 13<br />

@ Variable speed drive - page 14<br />

@ UNITY software - page 15<br />

@ Modicon ProWORX software - page 19<br />

@ Safety PLCs - page 20<br />

@ Clipsal C-Bus - pages 21-23<br />

@ Magelis HMI - page 24<br />

@ Vijeo Citect - pages 25-29<br />

@ Concept software - page 16, 17<br />

<strong>Training</strong> on <strong>Schneider</strong> <strong>Electric</strong> solutions<br />

@ Authorised Person: Industrial HV - page 32<br />

@ Authorised Person: Industrial LV - page 33<br />

@ Authorised Person: NHS Estates HV/LV - page 34<br />

@ Authorised Person (MOD): AP HV/LV - page 35<br />

@ Authorised Person (MOD): AP LV - page 36<br />

@ Authorised Person (MOD): APR HV - page 37<br />

@ Authorised Person (MOD): APHaz - page 38<br />

@ Protecting your distribution network - page 39<br />

@ Working safely with diesel generator<br />

systems - page 40<br />

@ Working safely with UPS systems - page 41<br />

<strong>Training</strong> on your day-to-day business issues<br />

@ Introduction to energy management - page 43<br />

@ 17th Edition wiring regulations (update) - page 44<br />

@ 17th Edition wiring regulations (comprehensive) - page 45<br />

@ Basic electrical foundation course - page 46<br />

@ Functional safety - SILs - page 47<br />

Practical information<br />

@ General conditions - page 49<br />

@ Booking form and credit card booking via fax - page 50<br />

5

6<br />

Choosing your best training paths

Choosing your best training paths<br />

We are committed to giving you precisely the training that you<br />

need, whether it’s a quick refresher or an in-depth immersion in<br />

your chosen topic. And, if our listed courses aren’t quite what you<br />

are looking for, please contact us for details of our customised<br />

courses – all of which can be delivered on your site if needed.<br />

Recommended courses to fit your job<br />

> Contractors/End Users<br />

@ Authorised Person - pages 32-38<br />

@ Introduction to energy management - page 43<br />

@ Protecting your distribution network - page 39<br />

@ Working safely with diesel generator systems - page 40<br />

@ Working safely with UPS systems - page 41<br />

@ GenieEvo / Ringmaster switchgear - page 10/11<br />

@ Sepam relays - page 12<br />

@ LV air circuit breakers - page 13<br />

@ Variable speed drives - page 14<br />

@ UNITY software - page 15<br />

@ Concept software - pages 16-17<br />

@ Modicon TSX PL7 Pro software - page 18<br />

@ Modicon ProWORX software - page 19<br />

@ Safety PLC - page 20<br />

@ Magelis HMI - page 24<br />

@ Vijeo Citect - pages 25-29<br />

@ 17th Edition wiring regulations - pages 44-45<br />

@ Functional safety - SILs - page 47<br />

> Installers/Panelbuilders<br />

@ Clipsal C-Bus - pages 21-23<br />

@ 17th Edition wiring regulations - pages 44-45<br />

@ Functional safety – SILs - page 47<br />

Courses <strong>by</strong> training topic<br />

> Automation<br />

@ UNITY software - page 15<br />

@ Concept software - pages 16-17<br />

@ Modicon TSX PL7 Pro software - page 18<br />

@ Modicon ProWORX software - page 19<br />

@ Clipsal C-Bus - pages 21-23<br />

@ Magelis HMI - page 24<br />

@ Safety PLC - page 20<br />

@ Vijeo Citect - pages 25-29<br />

> Power<br />

@ Authorised Person: Industrial - pages 32-33<br />

@ Authorised Person: NHS Estates - page 34<br />

@ Authorised Person: MOD - pages 35-38<br />

@ Introduction to energy management - page 43<br />

@ Protecting your distribution network - page 39<br />

@ Working safely with diesel generator<br />

systems - page 40<br />

@ Working safely with UPS systems - page 41<br />

@ GenieEvo switchgear - page 10<br />

@ Ringmaster switchgear - page 11<br />

@ Sepam relays - page 12<br />

@ LV air circuit breakers - page 13<br />

@ Variable speed drives - page 14<br />

7

8<br />

<strong>Training</strong> on<br />

<strong>Schneider</strong> <strong>Electric</strong> products

<strong>Training</strong> on <strong>Schneider</strong> <strong>Electric</strong> products<br />

@ GenieEvo switchgear - page 10<br />

@ Ringmaster switchgear - page 11<br />

@ Sepam relays - page 12<br />

@ LV air circuit breakers - page 13<br />

@ Variable speed drive - page 14<br />

@ UNITY software - page 15<br />

@ Concept software - page 16, 17<br />

@ Modicon TSX PL7 Pro software - page 18<br />

@ Modicon ProWORX software - page 19<br />

@ Safety PLCs - page 20<br />

@ Clipsal C-Bus - pages 21-23<br />

@ Magelis HMI - page 24<br />

@ Vijeo Citect - pages 25-29<br />

9

Protection/product courses<br />

GenieEvo switchgear<br />

The fundamental principle of controlling danger with the operation of High Voltage (HV) and Low Voltage (LV)<br />

circuit breakers lies at the centre of all networks, from a major transmission system, down to a simple radial LV<br />

distribution board. Failure of a device to operate correctly could result in serious damage and endanger personnel.<br />

These courses enable delegates to grasp the characteristics of these essential products, covering the correct<br />

installation and set up of breakers and its allied protection.<br />

Objectives<br />

@ Delegates will safely operate the circuit breaker to secure the<br />

point of isolation and earthing appropriately<br />

Content<br />

Overview presentation, with notes:<br />

@ Introduction to the switchgear<br />

@ Definition of the main variants and ratings<br />

@ Architecture and main components<br />

@ Evolis vacuum circuit breaker<br />

@ Controlled air disconnector<br />

@ Voltage transformer<br />

@ Endurance characteristics<br />

@ Overview of the Sepam protection system<br />

Target audience<br />

@ Your scope: Public and commercial<br />

buildings<br />

@ Your job: Maintenance manager, electrical<br />

engineer, facilities manager<br />

Prerequisite knowledge<br />

@ None<br />

Duration and delivery<br />

@ A one day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

Demonstration, followed <strong>by</strong> hands-on operation:<br />

@ Isolator and circuit breaker mechanism operation<br />

@ Cable testing facility<br />

@ Voltage transformer compartment<br />

@ Protection reset<br />

@ Visual checks<br />

Equipment used<br />

@ GenieEvo switchgear<br />

<strong>Training</strong> code: 118<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

10

Protection/product courses<br />

Ringmaster switchgear<br />

Objectives<br />

@ To teach the construction and operation of Ringmaster<br />

switchgear<br />

Target audience<br />

@ Your scope: Public and commercial<br />

buildings<br />

@ Your job: Maintenance manager, electrical<br />

engineer, facilities manager<br />

Content<br />

@ Introduction to the switchgear<br />

@ Definition of the main variants and ratings<br />

@ Architecture and main components<br />

@ Interruption system<br />

@ Gas pressure indication<br />

@ Endurance characteristics<br />

@ Overview of protection system (TFL or VIP300)<br />

@ Mechanism operation<br />

@ Cable testing facility<br />

@ Circuit breaker reset<br />

@ Protection reset<br />

@ Visual checks<br />

Equipment used<br />

@ Ringmaster switchgear<br />

Prerequisite knowledge<br />

@ None<br />

Duration and delivery<br />

@ A one day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 127<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

11

Protection/product courses<br />

Sepam relays<br />

Target audience<br />

@ Your scope: Public and commercial<br />

building<br />

@ Your job: Maintenance manager, electrical<br />

engineer, facilities manager<br />

Prerequisite knowledge<br />

@ Delegates attending this course will need<br />

a familiarity with PC and MS Windows<br />

Duration and delivery<br />

@ A one day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

Objectives<br />

@ To teach the operation and use of the Sepam 2000, 20, 40 or 80<br />

protection relay<br />

Content<br />

@ Introduction to the relay<br />

@ Definition of the main variants<br />

@ Architecture and main components<br />

@ Functionality<br />

@ PLC ladder logic overview<br />

@ PC setting software<br />

@ Metering functions<br />

@ Protection reset<br />

@ Post fault interrogation<br />

@ Disturbance recorder<br />

@ Protection settings<br />

@ I/O status<br />

@ Use of TSM handheld terminal adds further 1/2 day<br />

Equipment used<br />

@ Sepam protection relay and hand held terminal<br />

<strong>Training</strong> code: 116<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

12

Protection/product courses<br />

Operation and maintenance of LV air circuit breakers<br />

Objectives<br />

@ The purpose of this course is to provide a primary understanding<br />

of the operation of circuit breakers and to outline the relevant<br />

operational aspects of the unit<br />

Content<br />

@ Identify the circuit breaker standards<br />

@ Circuit breaker mechanical theory<br />

@ <strong>Electric</strong>al circuit breaker operation<br />

@ Levels of maintenance and servicing<br />

@ Important aspects of the control unit<br />

Target audience<br />

The course is designed for engineering<br />

staff concerned with operation and/or<br />

maintenance of the LV circuit breakers<br />

including:<br />

@ Public and commercial buildings<br />

@ Maintenance manager<br />

@ <strong>Electric</strong>al engineer<br />

@ Facilities manager<br />

@ Installation and operating staff<br />

@ Maintenance/repair teams<br />

@ Commissioning and test technicians<br />

@ Systems designers<br />

@ Panel manufacturers<br />

Equipment used<br />

@ Compact NS MCCB<br />

@ Masterpact air circuit breakers<br />

@ Control unit tester<br />

Prerequisite knowledge<br />

@ None<br />

Duration and delivery<br />

@ A one day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 106<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

13

Variable speed drive<br />

Objectives<br />

@ The course aims to provide a broad introduction to the principles<br />

of AC motor speed control using VSDs<br />

Delegates should be able to demonstrate an understanding of:<br />

@ The characteristics of AC induction motors<br />

@ How AC VSDs operate<br />

@ The difference between constant and variable torque<br />

applications<br />

@ The application functions provided <strong>by</strong> AC variable speed drives<br />

Content<br />

@ AC VSD and motor principles. Application and installation<br />

considerations, including constant and variable torque load<br />

characteristics<br />

@ Explanations and hands-on practical demonstrations of the key<br />

functions provided <strong>by</strong> modern AC VSDs<br />

Target audience<br />

@ Your scope: Industrial facilities<br />

@ Your job: Maintenance manager, facilities<br />

manager, operations manager<br />

Equipment used<br />

@ The course is conducted using Altivar drives, which can include:<br />

ATV11, ATV31, ATV38, ATV58, ATV71, ATV61<br />

Prerequisite knowledge<br />

@ None<br />

Duration and delivery<br />

@ Duration on application<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 337<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

14

Programmable logic controller<br />

UNITY software<br />

<strong>Schneider</strong> <strong>Electric</strong>’s range of Programmable Logic Controllers (PLCs) is market leading. With a wide range of<br />

processors, selecting a PLC to meet your personal needs is easy.<br />

With this in mind, our PLC courses are wide and varied, covering all PLC types and all programming software<br />

versions. With a selection of open courses available on request, both in our offices or on site, our flexible training<br />

schedules make it easy for you to meet your training needs.<br />

To back up our standard programming courses, customised training is available to cover all intelligent modules<br />

and all communications networks.<br />

Target audience<br />

@ Your scope: Facilities with automation<br />

systems using Quantum or Premium<br />

PLCs<br />

@ Your job: Maintenance manager, control<br />

engineer, operations manager, production<br />

manager<br />

Prerequisite knowledge<br />

@ Computer skills and basic PLC<br />

knowledge<br />

Duration and delivery<br />

@ A three day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 301<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ To teach the functions of the UNITY programming software<br />

Content<br />

@ Creating users using the security features<br />

@ Project settings<br />

@ Converting PL7 or Concept programs<br />

@ PLC configuration<br />

@ Programming<br />

- Function block diagram<br />

- Instruction list<br />

- Structured text<br />

- Ladder diagram<br />

- Sequential function chart<br />

@ Derived data types<br />

@ Derived function blocks<br />

@ Import and export of projects, sections etc<br />

Equipment used<br />

@ Premium or Quantum hardware<br />

@ UNITY programming software<br />

15

Programmable logic controller<br />

Concept level 1 application software<br />

Target audience<br />

@ Your scope: Facilities with automation<br />

systems using Quantum PLCs<br />

@ Your job: Maintenance manager, control<br />

engineer, operations manager, production<br />

manager<br />

Prerequisite knowledge<br />

@ Delegates attending this course will need<br />

a familiarity with PC and MS Windows<br />

Duration and delivery<br />

@ A three day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 319<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

By the end of the course students will be able to:<br />

@ Configure a PLC<br />

@ Develop simple programs in IEC editors<br />

@ Create derived function blocks<br />

@ Document programme<br />

Content<br />

@ Quantum hardware modules and configuration<br />

@ IEC 1131-3 overview<br />

@ Programming language editors<br />

@ FBD ladder<br />

@ Structured text<br />

@ Instruction list<br />

@ Derived function block<br />

@ Sequential function chart<br />

@ Application documentation<br />

@ Practical work<br />

Equipment used<br />

@ Concept software<br />

@ Quantum PLCs<br />

16

Programmable logic controller<br />

Concept level 2 application software<br />

Target audience<br />

@ Your scope: Facilities with automation<br />

systems using Quantum PLCs<br />

@ Your job: Maintenance manager, control<br />

engineer, operations manager, production<br />

manager<br />

Prerequisite knowledge<br />

@ Concept level 1 application course<br />

Duration and delivery<br />

@ A three day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 320<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

By the end of the course students will be able to:<br />

@ Configure a PLC<br />

@ Use security features<br />

@ Programme in all 5 IEC languages<br />

@ Create and use DFBs<br />

@ Create and use macros<br />

@ Create and use DDTs<br />

@ Create documentation<br />

@ Export/import programmes<br />

Content<br />

@ Quantum hardware modules and configuration<br />

@ IEC 1131-3 overview<br />

@ Programming languages FBD, SFC, LD, IL and ST<br />

@ Derived function blocks<br />

@ Derived data types<br />

@ Macros<br />

@ Documentation<br />

@ Practical work<br />

Equipment used<br />

@ Concept software<br />

@ Quantum PLCs<br />

17

Programmable logic controller<br />

Modicon TSX PL7 Pro level 1 application<br />

Target audience<br />

@ Your scope: Facilities with automation<br />

systems using Micro or Premium PLCs<br />

@ Your job: Maintenance manager, control<br />

engineer, operations manager, production<br />

manager<br />

Prerequisite knowledge<br />

@ A basic knowledge of Windows and PLCs<br />

would be helpful<br />

Duration and delivery<br />

@ A four day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 321<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

By the end of the course the student should<br />

have the skills to:<br />

@ Select and configure PLC hardware<br />

@ Understand the PL7 programming software<br />

@ Understand the PL7 language components<br />

@ Debug an application<br />

@ Conduct fault finding and maintenance<br />

@ Back-up applications<br />

@ Update application documentation<br />

Content<br />

@ Principles of programmable control<br />

@ Identification of PLC hardware<br />

@ Configuration of the PLC I/O modules<br />

@ System configuration<br />

@ Principles of programming and structures<br />

@ Principles of analogue operation<br />

@ Introduction to programming languages<br />

@ Ladder logic<br />

@ Text<br />

@ Sequence flow chart (Grafcet)<br />

@ Instruction list<br />

@ Practical exercises<br />

@ Application debugging, back-up and export<br />

@ Fault finding and maintenance<br />

@ Application documentation<br />

Equipment used<br />

@ Modicon TSX 37 Micro PLC<br />

@ Modicon TSX 57 Premium PLC<br />

@ PL7-Micro/Junior programming software<br />

18

Programmable logic controller<br />

Modicon ProWORX software level 1 application<br />

Target audience<br />

@ Your scope: Facilities with automation<br />

systems using Quantum, 984, Compact<br />

or Momentum PLCs<br />

@ Your job: Maintenance manager, control<br />

engineer, operations manager, production<br />

manager<br />

Prerequisite knowledge<br />

@ Basic knowledge of Windows. Some<br />

experience of plant control or introduction<br />

to PLCs would be desirable<br />

Duration and delivery<br />

@ A three day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 3313<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ Describe the basic principles of a PLC<br />

@ Recognise and name the major components of a PLC system<br />

@ Configuring a PLC<br />

@ Explanation of PLC I/O map<br />

@ Program basic ladder logic functions<br />

@ Transfer and save applications on PC<br />

@ Explain system diagnostics, maintenance and fault finding<br />

Content<br />

@ Principles of programmable control<br />

@ Overview of PLC hardware<br />

@ Configuring of applications<br />

@ Modicon PLC system theory<br />

@ Ladder programming language and<br />

methodology<br />

@ Practical examples and applications<br />

@ PLC trouble shooting techniques<br />

@ Overview of Modicon networking<br />

Equipment used<br />

@ Modicon 984, Compact, Momentum and Quantum PLCs<br />

@ ProWORX software<br />

- PLUS<br />

- NxT<br />

-32<br />

19

Programmable logic controller<br />

Safety PLCs<br />

Target audience<br />

@ Your scope: Facilities with PLC<br />

automation systems<br />

@ Your role: Installation engineer, control<br />

engineer, maintenance manager<br />

Prerequisite knowledge<br />

@ Participants should be familiar with the<br />

use of computers and the basic principles<br />

of PLC control systems<br />

Duration and delivery<br />

@ A two day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 355<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ Using practical exercises, participants will become familiar with<br />

both the software and hardware<br />

@ It is preferable that participants become familiar with safety<br />

principles and legislation before programming these PLCs<br />

Content<br />

@ Safety suite software installation<br />

@ Creating a new project and configuring a default resource (XPSMF35)<br />

@ Online controls, testing & diagnostic screens<br />

@ Creating a reset input<br />

@ Creating a function block (non-certified)<br />

@ Configuring a new resource (XPSMF30) in an existing project<br />

@ Modifying a function block <strong>by</strong> adding a direct value field<br />

@ Creating a multi-control panel<br />

@ Creating a line control input<br />

@ Peer to peer signal communication over Safe Ethernet<br />

@ Utilising the special Digital/Analogue inputs (XPSMF35) including<br />

adjusting the hysteresis values<br />

@ Utilising the special line control digital inputs (XPSMF35) for dual<br />

pole e-stop<br />

@ Setting up and using Modbus communications over Ethernet<br />

@ Software functions - AND, OR, NOT, Rising edge, and TON<br />

connected together with local and global variables<br />

Equipment used<br />

@ Safety PLCs - XPSMF35, XPSMF30 and remote I/O XPSMF3<br />

@ Safety Suite v1.0 software containing XPSMFWIN<br />

20

Lighting automation & control<br />

Clipsal C-Bus basic<br />

With the widespread focus on reducing energy, it is essential that we operate as efficiently as possible. These<br />

courses cover the control and automation of lighting in domestic and commercial premises via the Clipsal C-Bus<br />

product ranges.<br />

Objectives<br />

On completion of this course students should be able to:<br />

@ Understand the principles of C-Bus systems<br />

@ Plan and design a C-Bus system<br />

@ Use the C-Bus Toolkit software<br />

@ Program basic C-Bus units<br />

Target audience<br />

@ Your scope: Public, commercial and<br />

domestic premises<br />

@ Your job: Installers and designers of<br />

lighting control systems<br />

Prerequisite knowledge<br />

@ PC and MS Windows familiarity<br />

Content<br />

@ Introduction to the C-Bus system<br />

@ Examples of installations<br />

@ C-Bus operation<br />

@ Planning and design of a C-Bus installation<br />

@ Using the Toolkit software<br />

@ Configuring and programming C-Bus units<br />

@ Practical exercises<br />

Equipment used<br />

@ C-Bus dimmer<br />

@ PC interface<br />

@ PIR<br />

@ Light sensor and 4 way switch<br />

@ PC with Toolkit software installed<br />

Duration and delivery<br />

@ A two day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 401<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

21

Lighting automation & control<br />

Clipsal C-Bus intermediate 1<br />

Target audience<br />

@ Your scope: Public, commercial and<br />

domestic premises<br />

@ Your job: Installers and designers of<br />

lighting control systems<br />

Prerequisite knowledge<br />

@ Must have completed C-Bus basic<br />

Duration and delivery<br />

@ A one day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 402<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

On completion of this course students should be able to:<br />

@ Setup and configure a C-Bus network interface<br />

@ Program the monochrome touch screen<br />

Content<br />

@ Introduction to Ethernet<br />

@ Setting up the network interface using<br />

@ Lantronix software<br />

@ Programming basic functions on touch screen<br />

@ Using schedules and scenes<br />

@ Programming the DLT with key functions and scenes<br />

Equipment used<br />

@ C-Bus B/W touch screen<br />

@ Network Interface and Dynamic Labelling Technology (DLT) 5<br />

button unit<br />

@ PC with Toolkit and PICED software installed<br />

22

Lighting automation & control<br />

Clipsal C-Bus intermediate 2<br />

Target audience<br />

@ Your scope: Public, commercial and<br />

domestic premises<br />

@ Your job: Installers and designers of<br />

lighting control systems<br />

Prerequisite knowledge<br />

@ Must have completed C-Bus<br />

intermediate 1<br />

Duration and delivery<br />

@ A one day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 403<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

On completion of this course students should be able to:<br />

@ Program the colour touch screen<br />

Content<br />

@ Introduction to Ethernet<br />

@ Setting up the network interface using<br />

@ Lantronix software<br />

@ Programming basic functions on touch screen<br />

@ Using schedules and scenes<br />

@ Programming the DLT with key functions and scenes<br />

Equipment used<br />

@ C-Bus colour touch screen<br />

@ PC with Toolkit and PICED software installed<br />

23

Operator interface HMI and SCADA courses<br />

Magelis HMI<br />

Target audience<br />

@ Your scope: Facilities with HMI control<br />

using Magelis terminals<br />

@ Your job: Installation engineer, control<br />

engineer, maintenance manager<br />

Prerequisite knowledge<br />

@ Must have computer skills and a<br />

knowledge of Premium / Quantum PLCs<br />

Duration and delivery<br />

@ A two or four day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 300<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ To teach users and programmers how to program and use the<br />

Magelis XBTG and XBTGT operator screens<br />

Content<br />

@ Introduction to Vijeo designer software<br />

@ Create a simple project<br />

@ Inserting pages and page links<br />

@ Text displays, parameters<br />

@ Programming screen objects<br />

@ Using the simulator<br />

@ Downloading<br />

@ Grouping objects<br />

@ Audio messages<br />

Equipment used<br />

@ Magelis XBTG, XBTGT, XBTN / R, XBTP /E/HM/PM<br />

/ / @ Vijeo designer software v4.6<br />

24

Operator interface HMI and SCADA courses<br />

Vijeo Citect software - Basic<br />

Target audience<br />

@ Your scope: Facilities with PLC<br />

automation systems<br />

@ Your role: Installation engineer, control<br />

engineer, maintenance manager<br />

Prerequisite knowledge<br />

@ Participants must have basic computer<br />

skills and a working knowledge of PLC<br />

addresses<br />

Duration and delivery<br />

@ A three day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 358<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ Good understanding and competent in the use of Citect HMI /<br />

SCADA<br />

@ Able to communicate with PLCs using Citect HMI / SCADA<br />

@ Apply learning to your own site or project<br />

@ Troubleshoot problems and take appropriate action<br />

@ Maximise performance of your Citect HMI / SCADA application<br />

@ Use the online help and knowledge base effectively<br />

Content<br />

@ Operating the demonstration project<br />

@ Client configuration<br />

@ Managing projects<br />

@ Setting up communications<br />

@ Graphics<br />

@ Commands and controls<br />

@ Alarms<br />

@ Trends<br />

@ Process analyst<br />

@ Roles and licensing<br />

Equipment used<br />

@ Citect v7.0 software<br />

25

Operator interface HMI and SCADA courses<br />

Vijeo Citect software - Intermediate (Networking)<br />

Target audience<br />

@ Your scope: Facilities with PLC<br />

automation systems<br />

@ Your role: Installation engineer, control<br />

engineer, maintenance manager<br />

Prerequisite knowledge<br />

@ Must have completed Vijeo Citect Basic<br />

course 358 - see page 25<br />

Duration and delivery<br />

@ A two day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 361<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

This hands on course will give you insight into the principles behind<br />

networking in Citect SCADA including how Citect SCADA uses a<br />

network, redundancy, distributed servers and global clients<br />

Content<br />

@ Introduction to networking<br />

@ Networking Vijeo Citect<br />

@ Vijeo Citect redundancy<br />

@ Distributed servers<br />

@ Kernel and debugging<br />

@ Web client<br />

Equipment used<br />

@ Citect v7.0 software<br />

26

Operator interface HMI and SCADA courses<br />

Vijeo Citect software - Advanced (Customisation & Design)<br />

Target audience<br />

@ Your scope: Facilities with PLC<br />

automation systems<br />

@ Your role: Installation engineer, control<br />

engineer, maintenance manager<br />

Prerequisite knowledge<br />

@ Must have completed Vijeo Citect<br />

Intermediate course 361- see page 26<br />

Duration and delivery<br />

@ A three day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 362<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ This interactive course will give you insight into the principles<br />

behind customising Citect SCADA<br />

@ You will be using different programming techniques including<br />

Cicode and VBA. In addition you will learn about the Citect<br />

kernel and exchanging data between Citect SCADA and other<br />

applications<br />

Content<br />

@ Custom templates<br />

@ Genies<br />

@ Structured tag names<br />

@ Smart Genies<br />

@ Genie forms<br />

@ Smart popup pages and supergenies<br />

@ Cicode forms<br />

@ Custom navigation<br />

@ Custom menus<br />

@ True colour<br />

@ Graphics builder automation interface<br />

@ Citect SCADA and ODBC<br />

@ CiRecipe Active X control<br />

@ Active X and Cicode<br />

@ Active X events<br />

@ Process analyst<br />

@ The Citect kernel and debugging code<br />

@ Custom alarm filtering<br />

@ Table maths<br />

Equipment used<br />

@ Citect v7.0 software<br />

27

Operator interface HMI and SCADA courses<br />

Vijeo Citect – Cicode programming<br />

Target audience<br />

@ Your scope: Facilities with PLC<br />

automation systems<br />

@ Your role: Installation engineer, control<br />

engineer, maintenance manager<br />

Prerequisite knowledge<br />

@ Familiarity with the Windows operating<br />

system. Working knowledge of process<br />

control applications and Vijeo Citect<br />

Duration and delivery<br />

@ A two day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 363<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ This course is designed for engineering staff, maintenance staff<br />

and plant supervisors who have had some Citect configuration<br />

experience and want to use Citect’s advanced features<br />

Content<br />

@ Introductions to Cicode<br />

@ Commands - setting variables<br />

@ Expressions<br />

- Performing calculations<br />

- Displaying data<br />

- Multiple statements<br />

- Getting operator input<br />

@ Variable operators<br />

@ The Cicode editor – file navigation, editing tools<br />

@ Simple Cicode functions<br />

- Writing simple functions<br />

- Function syntax<br />

- Void functions<br />

- Cicode variables<br />

- Converting and formatting Cicode variables<br />

- Include files<br />

@ Conditional executors<br />

- IF statements<br />

- FOR loop<br />

- WHILE loop<br />

- SELECT CASE statement<br />

@ Return functions<br />

- Arrays<br />

- Comments<br />

- Debugging<br />

Equipment used<br />

@ Citect v7.0 software<br />

28

Operator interface HMI and SCADA courses<br />

Vijeo Citect – Historian<br />

Target audience<br />

@ Your scope: Facilities with PLC<br />

automation systems<br />

@ Your role: Installation engineer, control<br />

engineer, maintenance manager<br />

Prerequisite knowledge<br />

@ Familiarity with the Windows operating<br />

system. Working knowledge of process<br />

control applications and Vijeo Citect<br />

Duration and delivery<br />

@ A two day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 364<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ This course is designed for engineers who wish to configure and<br />

maintain a Citect SCADA report project and managers who wish<br />

to analyse the data in the client tools<br />

Content<br />

@ Data sources<br />

@ Historian<br />

@ Publishing information<br />

@ Managing projects<br />

@ Tasks<br />

@ Events<br />

@ Vijeo Historian web server client<br />

@ Excel client<br />

@ Statistical analysis in Excel<br />

@ SQL server 2005 reporting services<br />

@ Publishing data<br />

Equipment used<br />

@ Citect v7.0 software<br />

29

30<br />

<strong>Training</strong> on<br />

<strong>Schneider</strong> <strong>Electric</strong> solutions

<strong>Training</strong> on <strong>Schneider</strong> <strong>Electric</strong> solutions<br />

@ Authorised Person: Industrial HV - page 32<br />

@ Authorised Person: Industrial LV - page 33<br />

@ Authorised Person: NHS Estates HV/LV - page 34<br />

@ Authorised Person (MOD): AP HV/LV - page 35<br />

@ Authorised Person (MOD): AP LV - page 36<br />

@ Authorised Person (MOD): APR HV - page 37<br />

@ Authorised Person (MOD): APHaz - page 38<br />

@ Protecting your distribution network - page 39<br />

@ Working safely with diesel generator systems - page 40<br />

@ Working safely with UPS systems - page 41<br />

31

Authorised person courses<br />

High voltage authorised person (industrial)<br />

These courses are primarily designed for people operating High Voltage (HV) or Low Voltage (LV) electrical<br />

systems on site. Note, all of our Authorised Person courses contain practical exercises so delegates are advised<br />

to bring appropriate protective clothing.<br />

Objectives<br />

@ Delegates will be introduced to electrical systems and the<br />

dangers which exist and can arise when operating and working<br />

on HV and LV systems<br />

@ A facility for examining equipment and gaining hands on<br />

operating experience will be available throughout the course<br />

Target audience<br />

@ Your scope: Industrial, commercial and<br />

public facilities<br />

@ Your job: Nominated as Authorised<br />

Person, electrical maintenance manager<br />

Prerequisite knowledge<br />

@ None<br />

Duration and delivery<br />

@ A four day course (residential or<br />

non-residential options available)<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

<strong>Training</strong> code: 107<br />

Content<br />

@ The training will cover safe operating procedures relating to<br />

the operation and maintenance of a variety of manufacturers HV<br />

equipment<br />

@ Delegates will gain the required experience to issue<br />

documentation abiding <strong>by</strong> current legislation in addition to<br />

attaining the role of safety coordinator<br />

@ Statutory safety regulations<br />

@ HV switchgear operation and maintenance<br />

@ Operation and isolation of electrical distribution equipment<br />

@ Issue of Permit to Work<br />

@ Issue of Sanction to Test<br />

@ Network operations<br />

@ Application of <strong>Electric</strong>al Safety Regulations to high voltage<br />

equipment and systems<br />

@ Basic protection operations<br />

@ Cable location and identification<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

32

Authorised person courses<br />

Low voltage authorised person (industrial)<br />

Target audience<br />

@ Your scope: Industrial, commercial and<br />

public facilities<br />

@ Your job: Nominated as Authorised<br />

Person, electrical maintenance manager<br />

Prerequisite knowledge<br />

@ None<br />

Duration and delivery<br />

@ A three day course (residential or<br />

non-residential options available)<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

<strong>Training</strong> code: 101<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ The training will teach safe operating procedures relating to the<br />

operation and maintenance of a variety of equipment<br />

@ Delegates will gain the required experience to issue<br />

documentation abiding <strong>by</strong> current legislation in addition to<br />

attaining the role of safety coordinator<br />

Content<br />

@ Statutory safety regulations<br />

@ LV switchgear operation and maintenance<br />

@ Operation and maintenance of electrical distribution equipment<br />

@ Issue of Permit to Work<br />

@ Issue of Sanction to Test<br />

@ Network operations<br />

@ Application of <strong>Electric</strong>al Safety Regulations to LV equipment and<br />

systems<br />

@ Basic protection operations<br />

@ Cable location and identification<br />

Equipment used<br />

@ Various LV equipment<br />

33

Authorised person courses<br />

Authorised Person NHS estates in accordance with<br />

HTM 0602/0603<br />

Target audience<br />

@ Your scope: Health estate buildings<br />

@ Your job: Nominated as Authorised Person<br />

Prerequisite knowledge<br />

@ Delegates who attend the course<br />

should have a firm understanding of basic<br />

electrical principles and theory<br />

Duration and delivery<br />

@ A ten day course (residential)<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

<strong>Training</strong> code:<br />

140 (HV - HTM 0603)<br />

163 (LV - HTM 0602)<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ UK National Health Service course for the appointment of<br />

persons working to the HTM 0602/0603 <strong>Electric</strong>al Safety Code<br />

for Low Voltage/High Voltage systems<br />

@ This will apply to England and Wales and also covers the<br />

variations applicable to Scotland and Northern Ireland<br />

Content<br />

@ Management policy<br />

@ Statutory legislation<br />

@ HTM 0602/0603 roles and duties<br />

@ Safety programs<br />

@ Signs and notices<br />

@ Permits and sanctions in use<br />

@ Inspectorate<br />

@ <strong>Electric</strong>al apparatus construction, operation and maintenance<br />

@ Safe isolation of HV and LV systems<br />

@ Practical exercises on HV and LV<br />

@ Cable workings<br />

@ Protection applications, settings and testing<br />

@ Written test assessment<br />

34

Authorised person courses<br />

Authorised Person: AP HV/LV (MOD)<br />

Target audience<br />

@ Your scope: Defence estate maintenance<br />

management organisation (MMO)<br />

@ Your job: Nominated as Authorised Person<br />

Prerequisite knowledge<br />

@ Foundation training advisory<br />

Duration and delivery<br />

@ A ten day course (residential)<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

<strong>Training</strong> code: 110<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ Delegates will learn the essential requirements of safe working<br />

procedures on High Voltage (HV) equipment as required <strong>by</strong> the<br />

<strong>Electric</strong>ity at Work Regulations and Defence Estates<br />

JSP375 Safety Rules and Procedures<br />

Content<br />

@ Statutory safety regulations, mandatory safety regulations,<br />

Defence Estates, Safety Rules and Procedures (JSP375)<br />

@ HV switchgear operation and isolation<br />

@ HV ring and radial network operation<br />

@ Issue of Permit to Work and Sanction to Test<br />

@ Low Voltage (LV) distribution equipment<br />

@ Application of <strong>Electric</strong>al Safety Regulations to LV equipment and<br />

systems<br />

@ Operating records and documentation<br />

@ Cable location and identification<br />

@ Testing and commissioning of HV electrical distribution<br />

equipment<br />

@ Pressure (Hi-Pot) testing<br />

35

Authorised person courses<br />

Authorised Person: AP LV (MOD)<br />

Target audience<br />

@ Your scope: Defence estate maintenance<br />

management organisation (MMO)<br />

@ Your job: Nominated as Authorised Person<br />

Prerequisite knowledge<br />

@ Foundation training advisory<br />

Duration and delivery<br />

@ A five day course (residential)<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 151<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ Delegates will learn the essential requirements of safe working<br />

procedures on LV equipment as required <strong>by</strong> the <strong>Electric</strong>ity at<br />

Work regulations and Defence Estates JSP375 Safety Rules and<br />

Procedures<br />

Content<br />

@ Statutory safety regulations<br />

@ Mandatory safety regulations<br />

@ Defence Estates <strong>Electric</strong>al Safety Rules and Procedures<br />

@ LV distribution switchgear and equipment<br />

@ Application of electricity safety regulations<br />

@ Issue of Permit to Work and Sanction to Test<br />

@ Cable location and identification<br />

@ Operating records and documentation<br />

Equipment used<br />

@ A wide variety of manufacturers LV switchgear is installed for<br />

practical work<br />

36

Authorised person courses<br />

Authorised Person: APR HV (MOD)<br />

Target audience<br />

@ Your scope: Defence estate maintenance<br />

management organisation (MMO)<br />

@ Your job: Authorised Person requiring<br />

refresher training<br />

Prerequisite knowledge<br />

@ Must have completed AP HV/LV -<br />

see page 35<br />

Duration and delivery<br />

@ A five day course (residential)<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

<strong>Training</strong> code: 111<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ Delegates will revisit the essential requirements of safe working<br />

procedures on High Voltage (HV) equipment as required <strong>by</strong> the<br />

<strong>Electric</strong>ity at Work Regulations and Defence Estates<br />

JSP375 Safety Rules and Procedures<br />

Content<br />

@ Statutory safety regulations, mandatory safety regulations,<br />

Defence Estates, Safety Rules and Procedures (JSP375)<br />

@ HV switchgear operation and maintenance<br />

@ Operation and maintenance of electrical distribution equipment<br />

@ Issue of Permit to Work<br />

@ Issue of Sanction to Test<br />

@ Network operations<br />

@ Low Voltage (LV) distribution equipment<br />

@ Application of <strong>Electric</strong>al Safety Regulations to HV equipment and<br />

systems<br />

@ Operating records and documentation<br />

@ Cable location and identification<br />

37

Authorised person courses<br />

Authorised Person: APHaz (MOD)<br />

Target audience<br />

@ Your scope: Defence estate maintenance<br />

management organisation (MMO)<br />

@ Your job: Nominated as Authorised<br />

Person for hazardous area installations<br />

Prerequisite knowledge<br />

@ None<br />

Duration and delivery<br />

@ A three day course (residential)<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

<strong>Training</strong> code: 152<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

To enable delegates nominated for appointment as authorised<br />

persons to acquire the necessary background knowledge, skills<br />

and basis for gaining company experience.<br />

In particular:<br />

@ To revise and update the requirements and application of<br />

relevant legislation<br />

@ To learn procedures for a safe system of work on hazardous LV<br />

systems in accordance with JSP375<br />

@ To obtain practice in implementing the above<br />

Content<br />

@ British Standards (BS) and Cenelec (European) Standards and<br />

codes of practice<br />

@ The classification of areas and the choice of equipment for use in<br />

the presence of Potentially Explosive Atmospheres (PEXA)<br />

@ Certification of equipment methods of protection, gas groups<br />

and temperature classification<br />

@ Application and use of MoD Defence Estate (DE) Safety Rules<br />

and Procedures (JSP375)<br />

@ MoD/DE maintenance requirements for installation and<br />

maintenance of equipment<br />

@ Classroom and practical assessment exercises<br />

38

Protection/product courses<br />

Protecting your distribution network<br />

The fundamental principle of controlling danger with the operation of High Voltage (HV) and Low Voltage (LV)<br />

circuit breakers lies at the centre of all networks, from a major transmission system, down to a simple radial LV<br />

distribution board. Failure of a device to operate correctly could result in serious damage and endanger personnel.<br />

These courses enable delegates to grasp the characteristics of these essential products, covering the correct<br />

installation and set up of breakers and its allied protection.<br />

Target audience<br />

@ Your scope: Industrial, commercial and<br />

public facilities<br />

@ Your job: Designer, specifier or operator<br />

of HV networks, electrical engineer,<br />

maintenance manager, facilities manager<br />

Prerequisite knowledge<br />

@ None<br />

Duration and delivery<br />

@ A four day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

<strong>Training</strong> code: 109<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

By the end of the training the delegate will:<br />

@ Understand the factors involved in selecting a distribution<br />

network layout<br />

@ Have obtained expertise required to carry out protection<br />

co-ordination studies<br />

@ Understand how to select the optimum protection package for<br />

each application<br />

@ Understand the advantages of the integrated protection and<br />

control systems<br />

@ Be able to improve the performance of their electrical<br />

installations<br />

Content<br />

@ HV supplies and network configurations<br />

@ Estimation of system fault levels<br />

@ Instrument transformers<br />

@ Application of overcurrent and earth fault protection<br />

@ Differential protection<br />

@ Protection of transformers, motors and generators<br />

Equipment used<br />

@ Various protection relays<br />

@ The Sepam range of protection relays<br />

@ Ringmaster and YSF6 switchgear<br />

@ Talus and Sprite remote terminal units<br />

39

Protection/product courses<br />

Working safely with diesel generator systems<br />

Target audience<br />

@ Your scope: Industrial, commercial and<br />

public facilities<br />

@ Your job: Maintenance manager, electrical<br />

engineer, facilities manager<br />

Prerequisite knowledge<br />

@ None<br />

Duration and delivery<br />

@ A one day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

Objectives<br />

@ To teach safe operating procedures relating to the operation and<br />

maintenance of generator sets<br />

Content<br />

@ Statutory safety regulations relating to generator sets<br />

@ Generator set principles<br />

@ Safe isolation of generator sets<br />

@ Safety around a running engine<br />

Equipment used<br />

@ Cummins diesel generator set<br />

<strong>Training</strong> code: 112<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

40

Protection/product courses<br />

Working safely with UPS systems<br />

Objectives<br />

@ To teach safe operating procedures relating to the operation and<br />

maintenance of UPS equipment<br />

@ Delegates will gain the required experience to issue<br />

documentation abiding <strong>by</strong> all legislation and their specific<br />

company defined procedures<br />

Target audience<br />

@ Your scope: Industrial, commercial and<br />

public facilities<br />

@ Your job: Maintenance manager, electrical<br />

engineer, facilities manager<br />

Prerequisite knowledge<br />

@ None<br />

Content<br />

@ Statutory safety regulations relating to UPS<br />

@ UPS principles<br />

@ UPS associated switchgear<br />

@ Discrimination including earth loop impedance<br />

@ Fault levels relating to mains, generator, UPS and switchgear<br />

@ Practical operation of UPS and switchgear<br />

Equipment used<br />

@ UPS and associated switchgear<br />

Duration and delivery<br />

@ A two day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 160<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

41

42<br />

<strong>Training</strong> on<br />

your day-to-day business issues

Energy efficiency<br />

An introduction to energy management<br />

Target audience<br />

@ Your scope: All public and commercial<br />

premises<br />

@ Your role: Apprentice energy<br />

consultants preparing to undertake<br />

their first simple energy audits, facility<br />

managers attempting to understand<br />

areas for improvement within their sites,<br />

newly appointed energy managers<br />

and champions requiring an insight<br />

into energy saving techniques, quality<br />

improvement managers<br />

Prerequisite knowledge<br />

@ Intermediate IT skills especially in<br />

Microsoft Word and Excel, experience<br />

in basic report writing, strong analytical<br />

skills<br />

Duration and delivery<br />

@ A two day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

Objectives<br />

@ After taking this training, the participants should understand the<br />

key drivers for energy efficiency sufficient to enable the planning<br />

and production of an energy audit<br />

Content<br />

@ The background and key drivers to energy efficiency<br />

@ Basic data types relating to energy consumption<br />

@ Data collection and analysis techniques<br />

@ Overview of basic energy technologies<br />

- HVAC<br />

- Lighting<br />

- Processes<br />

- Refrigeration<br />

- Hot Water / steam generation<br />

@ Identifying areas for improvement<br />

@ Engineering calculations<br />

@ Planning, constructing and presenting an energy audit report<br />

<strong>Training</strong> code: 104<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

43

17th Edition wiring regulations<br />

Update course<br />

Target audience<br />

@ Your scope: All public, commercial and<br />

industrial organisations<br />

@ Your job: <strong>Electric</strong>al engineer, maintenance<br />

manager, electrical contractor<br />

Prerequisite knowledge<br />

Candidates wishing to take this course and<br />

arrange to take the City & Guilds 2382-20<br />

qualification must have achieved at least<br />

one of the following :-<br />

@ City & Guilds Level 3 Certificate in the<br />

requirements for <strong>Electric</strong>al Installations<br />

BS7671: June 2001 (2381)<br />

@ City & Guilds Level 3 Certificate in<br />

Electrotechnical Technology Installation<br />

(Building and Structures) (2330-07)<br />

@ City & Guilds Level 3 Certificate in<br />

Electrotechnical Technology <strong>Electric</strong>al<br />

Maintenance (2330-08)<br />

@ City & Guilds Level 3 Certificate in<br />

<strong>Electric</strong>al Installation Part Two (2360) from<br />

January 1st 2004 onwards<br />

Objectives<br />

@ This course is intended to meet the needs of experienced<br />

candidates who need to get up to speed quickly with the<br />

17th Edition Wiring Regulations and provides guidance on the<br />

main alterations and additions from the 16th edition incorporated<br />

in BS7671:2008<br />

Content<br />

@ Delegates will gain an understanding of the changes from the<br />

16th Edition and will be eligible to take the 17th Edition multiple<br />

choice test at a local GOLA centre (additional cost)<br />

Duration and delivery<br />

@ A one day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 168<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

44

17th Edition wiring regulations<br />

Comprehensive course<br />

Target audience<br />

@ Your scope: All public, commercial and<br />

industrial organisations<br />

@ Your job: <strong>Electric</strong>al engineer, maintenance<br />

manager, electrical contractor<br />

Prerequisite knowledge<br />

@ None - however it will be expected<br />

that delegates will have basic electrical<br />

knowledge<br />

@ This course is suitable for anyone<br />

who has no previous knowledge or<br />

qualification associated with the wiring<br />

regulations prior to 2001<br />

Duration and delivery<br />

@ A four day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 169<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ This course is intended to provide comprehensive training on all<br />

aspects of the 17th Edition Wiring Regulations<br />

@ The course is suitable for all electrical engineers, contractors,<br />

electricians or domestic installers who need to understand<br />

the principles behind the regulations and how it affects all<br />

aspects of their day to day work<br />

Content<br />

Delegates will complete the course with knowledge and practical<br />

understanding of all parts of the regulations:<br />

@ Scope, objective and fundamental principles<br />

@ Definitions<br />

@ Assessment of general characteristics<br />

@ Protection for safety<br />

@ Selection and erection of equipment<br />

@ Inspection and testing<br />

@ Special installations or locations<br />

@ Appendices<br />

Candidates will be eligible to take the 17th Edition exam<br />

C&G 2382-10 at a local GOLA centre following this course.<br />

Please note: There is an additional fee for taking the GOLA exam<br />

45

<strong>Electric</strong>al principles<br />

Basic electrical foundation course<br />

Target audience<br />

@ Your scope: All public, commercial and<br />

industrial organisations<br />

@ Your job: All staff who have very little<br />

knowledge of electricity<br />

Prerequisite knowledge<br />

@ Candidates must have completed<br />

the previous module before progressing<br />

throughout the course<br />

Duration and delivery<br />

@ A half day per module<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

Objectives<br />

This series of modules will provide the fundamental knowledge<br />

in electrical principles, danger awareness and highlight key<br />

operational considerations<br />

Content<br />

@ Module 1: Voltage, resistance & current<br />

@ Module 2: Calculations, faults & dangers<br />

@ Module 3: Protective devices<br />

@ Module 4: Magnetism<br />

@ Module 5: Power Supply Units and Variable Speed Drives<br />

@ Module 6: Control systems<br />

@ Module 7: Power factor<br />

@ Module 8: Open & closed loop control systems<br />

<strong>Training</strong> code: 100<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

46

Functional safety<br />

SILs<br />

Target audience<br />

@ Your scope: Industrial, commercial and<br />

public facilities<br />

@ Your job: Specifier, designer or<br />

maintenance of safety systems. <strong>Electric</strong>al<br />

engineer, facilities manager, maintenance<br />

manager, electrical contractor<br />

Prerequisite knowledge<br />

@ None<br />

Duration and delivery<br />

@ A one day course<br />

@ In-class sessions within<br />

<strong>Schneider</strong> <strong>Electric</strong> training centres<br />

@ Can be customised and delivered on<br />

customer premises<br />

<strong>Training</strong> code: 042<br />

For further information<br />

or registration<br />

@ Contact your local <strong>Schneider</strong> <strong>Electric</strong><br />

customer training centre<br />

Objectives<br />

@ This course will give users and system builders an overview<br />

of safety systems and the practical implementation of functional<br />

safety standards BS EN 61508 and its associated ‘sector<br />

implementation’ standards 61511, 62061 and 61513 with<br />

particular reference to safety integrity levels and safety life cycle<br />

Content<br />

@ Definition of SILs and what they mean<br />

@ Introduces HSE concepts of ALARP (As Low As Reasonably<br />

Practical) and tolerable risk<br />

@ Cover how the standards relate to each other and how they<br />

fit with UK regulations and the HSE’s published view of the<br />

standards<br />

@ Discuss how the standard is not just for instrument engineers as<br />

will become evident when going through the life-cycle below<br />

@ Safety life cycle activities:<br />

- Life cycle planning<br />

- Hazard and risk assessments<br />

- Safety requirements specification (SRS)<br />

- Safety instrumented system (SIS)<br />

- Testing<br />

- Operation & maintenance<br />

- Decommissioning<br />

47

<strong>Training</strong> <strong>by</strong> <strong>Schneider</strong> <strong>Electric</strong><br />

Practical information

<strong>Training</strong> <strong>by</strong> <strong>Schneider</strong> <strong>Electric</strong><br />

General conditions<br />

Payment<br />

Cheques must be made payable to<br />

<strong>Schneider</strong> <strong>Electric</strong> Ltd and should<br />

accompany the booking form which must<br />

reach us at least 4 weeks prior to the<br />

course start date to secure a place.<br />

Telephone bookings<br />

These are accepted subject to written<br />

confirmation.<br />

Confirmation<br />

Upon receipt of payment, course<br />

confirmation and joining instructions will be<br />

forwarded giving details of time, location<br />

and travel information.<br />

Cancellation <strong>by</strong><br />

participants<br />

Cancellation must be made in writing 4<br />

weeks prior to the course commencement<br />

for a full refund. Thereafter the full course<br />

fee is forfeited. However, substitutions will<br />

be accepted at any time for confirmed<br />

course places.<br />

Cancellation <strong>by</strong><br />

<strong>Schneider</strong> <strong>Electric</strong> Ltd<br />

The <strong>Schneider</strong> <strong>Electric</strong> Customer <strong>Training</strong> Centre reserves the right<br />

to cancel any proposed course and will give as much notice as is<br />

reasonable and practical.<br />

In the event that a course cannot be held or completed, <strong>Schneider</strong><br />

<strong>Electric</strong> Ltd will endeavour to re-schedule the course within a<br />

reasonable period. Should it not be possible to agree a mutually<br />

acceptable date then a full refund of fees already paid will be<br />

made.<br />

<strong>Schneider</strong> <strong>Electric</strong> Ltd cannot be held liable for failure to provide an<br />

alternative or for any costs arising from the cancellation.<br />

Prices<br />

Unless otherwise stated prices include documentation, lunch and<br />

refreshment but do not include evening meals, accommodation<br />

or any travel costs. Delegates are responsible for their own hotel<br />

bookings on non-residential courses.<br />

Health & Safety at Work Act<br />

The customer must ensure that all participants are aware of their<br />

responsibilities under the Health & Safety at Work Act.<br />

Copyright<br />

<strong>Schneider</strong> <strong>Electric</strong> Ltd may provide course notes and other training<br />

materials which are intended for the sole use of the individuals<br />