AMMTIAC Quarterly, Vol. 2, No. 2 - Advanced Materials ...

AMMTIAC Quarterly, Vol. 2, No. 2 - Advanced Materials ...

AMMTIAC Quarterly, Vol. 2, No. 2 - Advanced Materials ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

techsolutions 5<br />

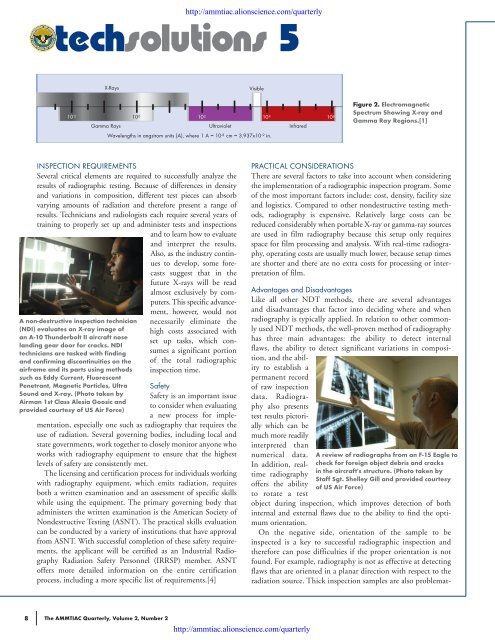

X-Rays<br />

Visible<br />

10 -2 10 2 10 4 10 6<br />

Gamma Rays Ultraviolet Infrared<br />

Wavelengths in angstrom units (A), where 1 A = 10 -8 cm = 3.937x10 -9 in.<br />

Figure 2. Electromagnetic<br />

Spectrum Showing X-ray and<br />

Gamma Ray Regions.[1]<br />

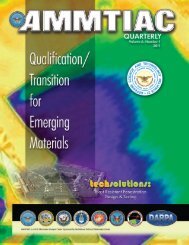

10 0 A review of radiographs from an F-15 Eagle to<br />

INSPECTION REQUIREMENTS<br />

Several critical elements are required to successfully analyze the<br />

results of radiographic testing. Because of differences in density<br />

and variations in composition, different test pieces can absorb<br />

varying amounts of radiation and therefore present a range of<br />

results. Technicians and radiologists each require several years of<br />

training to properly set up and administer tests and inspections<br />

and to learn how to evaluate<br />

and interpret the results.<br />

Also, as the industry continues<br />

to develop, some forecasts<br />

suggest that in the<br />

future X-rays will be read<br />

almost exclusively by computers.<br />

This specific advancement,<br />

however, would not<br />

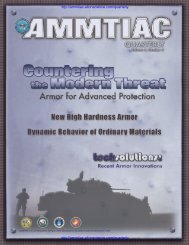

A non-destructive inspection technician<br />

(NDI) evaluates an X-ray image of<br />

an A-10 Thunderbolt II aircraft nose<br />

landing gear door for cracks. NDI<br />

technicians are tasked with finding<br />

and confirming discontinuities on the<br />

airframe and its parts using methods<br />

such as Eddy Current, Fluorescent<br />

Penetrant, Magnetic Particles, Ultra<br />

Sound and X-ray. (Photo taken by<br />

Airman 1st Class Alesia Goosic and<br />

provided courtesy of US Air Force)<br />

necessarily eliminate the<br />

high costs associated with<br />

set up tasks, which consumes<br />

a significant portion<br />

of the total radiographic<br />

inspection time.<br />

Safety<br />

Safety is an important issue<br />

to consider when evaluating<br />

a new process for implementation,<br />

especially one such as radiography that requires the<br />

use of radiation. Several governing bodies, including local and<br />

state governments, work together to closely monitor anyone who<br />

works with radiography equipment to ensure that the highest<br />

levels of safety are consistently met.<br />

The licensing and certification process for individuals working<br />

with radiography equipment, which emits radiation, requires<br />

both a written examination and an assessment of specific skills<br />

while using the equipment. The primary governing body that<br />

administers the written examination is the American Society of<br />

<strong>No</strong>ndestructive Testing (ASNT). The practical skills evaluation<br />

can be conducted by a variety of institutions that have approval<br />

from ASNT. With successful completion of these safety requirements,<br />

the applicant will be certified as an Industrial Radiography<br />

Radiation Safety Personnel (IRRSP) member. ASNT<br />

offers more detailed information on the entire certification<br />

process, including a more specific list of requirements.[4]<br />

PRACTICAL CONSIDERATIONS<br />

There are several factors to take into account when considering<br />

the implementation of a radiographic inspection program. Some<br />

of the most important factors include: cost, density, facility size<br />

and logistics. Compared to other nondestructive testing methods,<br />

radiography is expensive. Relatively large costs can be<br />

reduced considerably when portable X-ray or gamma-ray sources<br />

are used in film radiography because this setup only requires<br />

space for film processing and analysis. With real-time radiography,<br />

operating costs are usually much lower, because setup times<br />

are shorter and there are no extra costs for processing or interpretation<br />

of film.<br />

Advantages and Disadvantages<br />

Like all other NDT methods, there are several advantages<br />

and disadvantages that factor into deciding where and when<br />

radiography is typically applied. In relation to other commonly<br />

used NDT methods, the well-proven method of radiography<br />

has three main advantages: the ability to detect internal<br />

flaws, the ability to detect significant variations in composition,<br />

and the ability<br />

to establish a<br />

permanent record<br />

of raw inspection<br />

data. Radiography<br />

also presents<br />

test results pictorially<br />

which can be<br />

much more readily<br />

interpreted than<br />

numerical data.<br />

In addition, realtime<br />

radiography<br />

check for foreign object debris and cracks<br />

in the aircraft's structure. (Photo taken by<br />

Staff Sgt. Shelley Gill and provided courtesy<br />

offers the ability of US Air Force)<br />

to rotate a test<br />

object during inspection, which improves detection of both<br />

internal and external flaws due to the ability to find the optimum<br />

orientation.<br />

On the negative side, orientation of the sample to be<br />

inspected is a key to successful radiographic inspection and<br />

therefore can pose difficulties if the proper orientation is not<br />

found. For example, radiography is not as effective at detecting<br />

flaws that are oriented in a planar direction with respect to the<br />

radiation source. Thick inspection samples are also problemat-<br />

8<br />

The <strong>AMMTIAC</strong> <strong>Quarterly</strong>, <strong>Vol</strong>ume 2, Number 2