SEED TESTING The main objective of seed testing ... - SeedNet India

SEED TESTING The main objective of seed testing ... - SeedNet India

SEED TESTING The main objective of seed testing ... - SeedNet India

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SEED</strong> <strong>TESTING</strong><br />

<strong>The</strong> <strong>main</strong> <strong>objective</strong> <strong>of</strong> <strong>seed</strong> <strong>testing</strong> is to assess the actual planting value <strong>of</strong> the <strong>seed</strong> in<br />

terms <strong>of</strong> its germination capacity besides determination <strong>of</strong> percentage composition <strong>of</strong> the<br />

pure <strong>seed</strong>s, weed <strong>seed</strong>s, other crop species, extraneous matter and moisture content <strong>of</strong> the<br />

submitted sample.<br />

Seed <strong>testing</strong> procedures<br />

Registration <strong>of</strong> <strong>seed</strong> samples: <strong>The</strong> submitted samples should be <strong>of</strong> the specified weight.<br />

<strong>The</strong> accepted sample is registered for <strong>testing</strong> and is given a code number so as to <strong>main</strong>tain<br />

the secrecy about its identity during <strong>testing</strong>. <strong>The</strong> details <strong>of</strong> the samples such as crop,<br />

variety, class <strong>of</strong> <strong>seed</strong>, tests required etc. are entered in individual <strong>seed</strong> analysis cards.<br />

Working sample <strong>of</strong> specified size is obtained from the submitted sample by using the <strong>seed</strong><br />

dividers.<br />

Physical purity analysis: <strong>The</strong> purity analysis is done on a working sample <strong>of</strong> prescribed<br />

weight drawn from the submitted sample. <strong>The</strong> working sample is separated into different<br />

components like pure <strong>seed</strong>, other crop <strong>seed</strong>, weed <strong>seed</strong> and inert matter by physical<br />

examination and the details are recorded in the individual analysis card. <strong>The</strong> composition <strong>of</strong><br />

different components is expressed either in percentage by weight or as numbers per<br />

kilogram.<br />

Germination <strong>testing</strong>: <strong>The</strong> pure <strong>seed</strong> fraction from the purity test is used for germination<br />

analysis. A minimum <strong>of</strong> four hundred <strong>seed</strong>s in replications as per convenience are tested for<br />

germination. <strong>The</strong> most important requirements for <strong>seed</strong> germination <strong>testing</strong> are substrata,<br />

moisture, temperature and light.<br />

Substrata<br />

<strong>The</strong> substrate serves as a moisture reservoir and acts as a medium for the <strong>seed</strong>s to<br />

germinate and the <strong>seed</strong>lings to grow. <strong>The</strong> commonly used substrates are paper and sand.<br />

<strong>The</strong> standard Kraft paper (towel), filter paper and blotters are the widely used paper<br />

substrates. Sterilized sand with a particle size between 0.045 mm to 0.85mm is used for<br />

germination test.<br />

Methods <strong>of</strong> using substrata<br />

Top <strong>of</strong> paper (T.P): In this method <strong>seed</strong>s are placed directly on one or more layers <strong>of</strong><br />

moist filter or blotter papers in Petri dishes or plastic boxes which are in turn kept for<br />

incubation. This method is used for small sized crop <strong>seed</strong>s like ragi, jute, onion, tomato etc.<br />

Between paper (B.P.): Seeds are placed in between two moist germination papers and<br />

rolled together to look like a rolled towel. <strong>The</strong> rolled towels are placed inside the<br />

germination cabinet/room for incubation.<br />

Sand substrata: Plastic boxes are filled with sterilized sand <strong>of</strong> recommended particle size<br />

upto 3/4th <strong>of</strong> box height. <strong>The</strong> sand is moistened upto 50% <strong>of</strong> its water holding capacity.<br />

<strong>The</strong> <strong>seed</strong>s are planted on the leveled layer <strong>of</strong> moist sand and covered with 10-20 mm <strong>of</strong><br />

uncompressed sand depending on the size <strong>of</strong> the <strong>seed</strong>. Irrespective <strong>of</strong> the method, the<br />

substratum is made wet sufficiently and uniformly before putting the <strong>seed</strong>s for germination<br />

test and they are incubated either in a cabinet <strong>seed</strong> germinator or a walk-in germinator<br />

room where the temperature and relative humidity are regulated as per the prescribed

specifications. For most <strong>of</strong> the agricultural and horticultural <strong>seed</strong>s the temperature range <strong>of</strong><br />

20° C to 35°C and the relative humidity level <strong>of</strong> 90% and above is <strong>main</strong>tained in the <strong>seed</strong><br />

germinator/germinator room. Light is not very much essential for <strong>seed</strong> germination except<br />

for crops like lettuce and tobacco.<br />

Duration <strong>of</strong> the test<br />

<strong>The</strong> duration <strong>of</strong> sample incubation varies from crop to crop. For most <strong>of</strong> the crops first<br />

'count is taken' on the 4th or the 5th day and the final count between 7 to 10 days. <strong>The</strong><br />

time for count is fixed in such a way that it is sufficient to allow <strong>seed</strong>lings to reach a stage<br />

<strong>of</strong> development which allows for accurate evaluation. In case <strong>of</strong> sand media tests, the first<br />

count is omitted. <strong>The</strong> test can be terminated before the end <strong>of</strong> prescribed test period, if the<br />

sample under test meets the minimum limits <strong>of</strong> germination during the first count.<br />

Seedling, Evaluation<br />

During each count, the germinated <strong>seed</strong>lings and the re<strong>main</strong>ing ungerminated <strong>seed</strong>s are<br />

classified in to any <strong>of</strong> the following 5 categories.<br />

Normal <strong>seed</strong>lings: Seedlings which shows the capacity for continued development into<br />

mature plant when grown under favorable conditions and having well developed root and<br />

the shoot system.<br />

Abnormal <strong>seed</strong>lings: Seedlings with any abnormality in their root or shoot system thus<br />

which do not have the capacity to develop into a normal plant when grow.<br />

Hard <strong>seed</strong>s: Seeds which re<strong>main</strong> hard at the end <strong>of</strong> the prescribed test period because <strong>of</strong><br />

the non absorption <strong>of</strong> moisture due to the presence <strong>of</strong> impermeable <strong>seed</strong> cost. Usually hard<br />

<strong>seed</strong>s are seen in leguminous crops.<br />

Fresh ungerminated <strong>seed</strong>s: Seeds other than hard <strong>seed</strong>s, which re<strong>main</strong> firm, fresh and<br />

apparently viable, even at the end <strong>of</strong> the test period.<br />

Dead <strong>seed</strong>s: Seeds which at the end <strong>of</strong> the test period are neither hard nor fresh and<br />

have not produced <strong>seed</strong>lings are classified as dead <strong>seed</strong>s. Dead <strong>seed</strong>s <strong>of</strong>ten show the<br />

symptoms <strong>of</strong> decaying and fungal growth which can be felt by pressing the <strong>seed</strong> under<br />

test.<br />

Germination percentage<br />

<strong>The</strong> replication wise details <strong>of</strong> all categories <strong>of</strong> <strong>seed</strong>lings / <strong>seed</strong>s observed during evaluation<br />

are recorded in the <strong>seed</strong> analysis card. <strong>The</strong> result <strong>of</strong> germination test is calculated as the<br />

average <strong>of</strong> the replicates and is expressed as percentage by number <strong>of</strong> normal <strong>seed</strong>lings.<br />

<strong>The</strong> percentage is calculated to the nearest whole number. <strong>The</strong> percentage <strong>of</strong> abnormal<br />

<strong>seed</strong>lings, hard, fresh ungerminated and<br />

dead <strong>seed</strong>s is also calculated the same manner.<br />

Re<strong>testing</strong><br />

When the test results are unsatisfactory due to out <strong>of</strong> tolerance performance between<br />

replicates or : wrong evaluation <strong>of</strong> <strong>seed</strong>lings or : errors in <strong>testing</strong> conditions, a second test<br />

is conducted by the same method or by alternative method to confirm the results before<br />

they are declared.<br />

Moisture determination<br />

Seed moisture content is determined by using hot air oven or moisture meter. Seed<br />

moisture content is expressed as percentage by weight.<br />

Hot air oven method<br />

Here the <strong>seed</strong> moisture is removed by drying the pre-weighted sample at a specified<br />

temperature. <strong>The</strong> difference in weight is taken as moisture content and is expressed as a<br />

percentage <strong>of</strong> original weight. This is the most standard and accurate method <strong>of</strong> <strong>seed</strong><br />

moisture determination.

Moisture meter method<br />

Here the moisture content is determined using moisture meter which is calibrated and<br />

standardized against air oven method. Moisture test is conducted in two replications and<br />

the average is recorded in the <strong>seed</strong> analysis card.<br />

Back

1/<br />

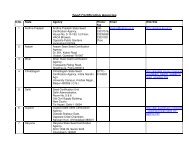

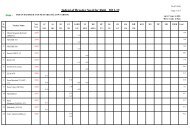

PRESCRIBE <strong>SEED</strong> STANDARDS FOR CROPS UNDER CERTIFICATION<br />

f<br />

Crop<br />

Germination Moisture Pure Seed Inert Matter O.C.S.' O.D.V.4 O.W.S.s<br />

(minimum) (maximum) (minimum) (maximum)(maximum) (maximum) (maximum)<br />

F C F C F C F C F C F C F C<br />

% Number per Kg<br />

Paddy<br />

80 80 13.0 13.0 98.0 98.0 2.0' 2.0 10 20 10 20 10 20<br />

Ragi<br />

75 75 12.0 12.0 97.0 97.0 3.0 3.0 10 20<br />

10 20<br />

Jowar<br />

75 75 12,0 12.0 97.0 97.0 3.0 3.0 10 20 10 20 5 10<br />

Wheat<br />

85 85 12.0 12.0 98.0 98.0 2.0 2.0 10 20<br />

10 20<br />

Maize<br />

a. Hybrids<br />

90 12.0 - 98.0 - 2.0 10 10 none<br />

b. Inbredsand 80 12.0 - 98.0 - 2.0 5 5<br />

none -<br />

singlecrosses<br />

c. Compositesand 90 90 12.0 12.0 98.0 98.0 2.0 2.0 10 20<br />

none none<br />

synthetics<br />

Bajra<br />

75 75 12.0 12.0 98.0 98.0 2.0 2.0 10 20<br />

10 20<br />

Redgram<br />

75** 75** 9.0 9.0 98.0 98.0 2.0 2.0 5 10 10 20 5 10<br />

Greengram and 75** 75** 9.0 9.0 98.0 98.0 2.0 2.0 5 10 10 20 5 10<br />

blackgram<br />

Horsegram<br />

80 80 9.0 9.0 98.0 98.0 2.0 2.0 none 10 5 20 none none<br />

Bengalgram<br />

85** 85** 9.0 9.0 98.0 98.0 2.0 2.0 none 10 5 20 none none<br />

Cowpea<br />

75** 75** 9.0 9.0 98.0 98.0 2.0 2.0 none 10 5 20 none 10<br />

Castor<br />

70 70 8.0 9.0 98.0 98.0 2.0 2.0 none 10 5 10 none none<br />

Groundnut<br />

70 70 8.0 9.0 98.0 98.0 4.0 4.0 none - 10 none none<br />

Sunflower<br />

70 70 9.0 9.0 98.0 98.0 2.0 2.0 none none none none 5 10<br />

Safflower<br />

80 80 9.0 9.0 98.0 98.0 2.0 2.0 none none none none 5 10<br />

Sesamum<br />

80 80 9.0 9.0 97.0 97.0 3.0 3.0 10 20 10 20 10 20<br />

Niger<br />

80 80 9.0 9.0 98.0 98.0 2.0 2.0 10 20 10 20 10 20<br />

Soyabean<br />

70*' 70*' 12.0 12.0 98.0 98.0 2.0 2.0 none 10 5 10 5 10<br />

Cotton<br />

65 65 10.0 10.0 98.0 98.0 2.0 2.0 5 10<br />

5 10<br />

Jute<br />

80 80 9.0 9.0 97.0 97.0 3.0 3.0 10 20 10 20 10 20<br />

Bhendi<br />

65*' 65** 10.0 10.0 99.0 99.0 1.0 1.0 none 5 10 20 none none<br />

Brinjal<br />

70 70 8.0 8.0 98.0 98.0 2.0 2.0 none none -<br />

none none<br />

Tomato<br />

70 70 8.0 8.0 98.0 98.0 2.0 2.0 5 10<br />

none none<br />

Capsicumand 60 60 8.0 8.0 98.0 98.0 2.0 2.0 5 10 0 0 5 10<br />

chilli<br />

Cluster bean<br />

70 70 9.0 9.0 98.0 98.0 2.0 2.0 10 20 10 20 none none<br />

Peas<br />

75 75 9.0 9.0 98.0 98.0 2.0 2.0 none 5 5 10 none none<br />

Bottlegourd<br />

60 60 7.0 7.0 98.0 98.0 2.0 2.0 none none -<br />

none none<br />

and pumpkin<br />

Watermelonand<br />

ridgelbitter gourd<br />

Frenchbean<br />

60<br />

75<br />

60<br />

75<br />

7.0<br />

9.0<br />

7.0<br />

9.0<br />

98.0<br />

98.0<br />

98.0<br />

98.0<br />

2.0<br />

2.0<br />

2.0<br />

2.0<br />

none none 5<br />

none none 5<br />

10<br />

10<br />

none none<br />

none 10<br />

"F' foundation, 2'C'-~ertified, 30.C.S.-other crop <strong>seed</strong>s, 40.D.V.-other distinguisha.blevarieties, 5W.S.- weed <strong>seed</strong>s,<br />

.OW.S. - objectionable weed <strong>seed</strong>s, ** - including hard <strong>seed</strong>s.<br />

<strong>SEED</strong> STANDARDS FOR INSECT DAMAGE<br />

A <strong>seed</strong> lot under certification shall not have apparent or visible evidence <strong>of</strong> damage by insects for both<br />

foundation and certified <strong>seed</strong> classes in excess <strong>of</strong> 1.0% for the <strong>seed</strong>s <strong>of</strong> maize and legumes and 0.50%<br />

for <strong>seed</strong>s other maize and 'Iegumes unless prescribed. .<br />

~F;

GROW-OUTTEST FOR G~!>JETIl;PURITY<br />

<strong>The</strong> Agency conducts grow-out test to determine<br />

genetic purity <strong>of</strong> a <strong>seed</strong> lot wherever it is a prerequisite<br />

for grant <strong>of</strong> certificate and also on the <strong>seed</strong> lots where doubt has arisen about the genetic purity<br />

<strong>SEED</strong> STANDARDS FOR GENETIC PURITY<br />

otherwise<br />

All certified <strong>seed</strong> lots shall conform to the following minimum standards for genetic purity unless<br />

prescribed.<br />

Class Minimum genetic;: purity (%)<br />

Foundation<br />

99.0<br />

Certified<br />

a. Varieties, composites, synthetics 98.0<br />

b. Hybrids (except cotton and castor hybrids) 95.0<br />

Cotton hybrids . 90.0<br />

Castorhybrids . 85.0<br />

*Off-type plants other than selfed plants such as segregants, out crosses and plants <strong>of</strong> other<br />

varieties should not exceed 1.5%<br />

REPORTING OF RESULTS<br />

All the observations recorded in the <strong>seed</strong> analysis card are checkedfor proper entry and calculations<br />

before reporting. <strong>The</strong> results are then decoded and transferred to the <strong>seed</strong> analysis report for further<br />

communication to the sender <strong>of</strong> the sample. .<br />

RECOMMENDED <strong>SEED</strong> TREATMENTS<br />

Crop Chemical Name Quantity <strong>of</strong> chemical (g)/ Method <strong>of</strong><br />

100 kg <strong>seed</strong> Water (litre) treatment<br />

I'<br />

Paddy Thiram 75 WDP 100<br />

(except Jyothi)<br />

Jyothi Bavistin 100<br />

Bajra Thiram 75 WDP or 100 0.5 Slurry treatment<br />

Thiram 75 Dust or 300 -<br />

Dry dressing<br />

Captan 75 Dust 300 - Dry dressing<br />

Brine 10% solution Solution to completely immerse <strong>seed</strong><br />

Sorghum Thiram 75 WDP 100 0.5 Slurry treatment<br />

Captafol 100 0.5 Slurry treatment<br />

Wheat Thiram 75 WDP <strong>of</strong> 100 0.5 Slurry treatment<br />

Mancozeb or 100 0.5 Slurry treatment<br />

Carboxin or 50 - Dry dressing<br />

Carbendazim2 '250 -<br />

Dry dressing<br />

Maize Thiram 75 WDP 100 0.5 Slurry treatmnt<br />

':1.1':

"<br />

-<br />

Crop Chemical Name Quantity <strong>of</strong> chemical (g)/ Method <strong>of</strong><br />

100 kg <strong>seed</strong> Water (litre) treatment<br />

Bengalgram Captafol 250 - Drydressing<br />

Blackgram Thiram 75 Dust 250 - Drydressing<br />

Cowpea Captan 75 WDP or 100 0.5 Slurrytreatment<br />

Thiram 75 Dust 250 - Drydressing<br />

Greengram Thiram 75 WDP 100 0.5 Slurrytreatment<br />

Redgram Thiram 75 WDP 100 0.5 Slurrytreatment<br />

Sunflower ." Thiram75 Dust 250 - Drydressing<br />

Groundnut Captan75 Dustor 250 - Drydressing<br />

Thiram 75 WDP or 125 0.5 Slurrytreatment<br />

.<br />

Captafol 200 - Drydressing<br />

Castor Organomercurial (1%) 250 -<br />

Drydressing<br />

Soyabean Captan75 Dustor 150 - Drydressing<br />

Thiram 75 Dust or<br />

Mancozeb or 300 - Drydressing<br />

Captafol. 300 -<br />

Drydressing<br />

Sesamum Thiram 75 Dust 300 - Drydressing.<br />

Cotton Captan75 Dustor 250 - Drydressing<br />

Thiram 75 WDP 100 0.5 Slurrytreatment<br />

Jute Captan 75 WDP 80 0.5 Slurrytreatment<br />

Mesta Captan 75 Dust' 250 -<br />

Drydressing<br />

Beans Captan 75 WDP or 100 0.5 Slurrytreatment<br />

Thiram 75 Dust 250 - Drydressing<br />

Bhendi Thiram 75 Dust or 100 0.5 Slurrytreatment<br />

Captan 75 Dust 250 -<br />

Drydressing<br />

Brinjal Thiram 75 Dust or. 250 -<br />

Drydressing<br />

Captan75 Dust 250 - Drydressing<br />

Chilli Thiram75 Dust. 250 - Drydresing<br />

Clusterbean Thiram 75 WDP ..100 0.5 Slurrytreatment<br />

Colecrops Thiram '75Dust 250 - Diy dressing<br />

. Cucurbits Thiram 75 Dust 250 - Drydressing<br />

Captan75 WDP 250 -<br />

Drydressing<br />

Onion Thiram75 Dust 250 -<br />

Dry dressing<br />

Tomato Thiram 75 Dust 250 -<br />

Dry dressing<br />

7

Note: 1. Brine (10%) is prepared by dissolving 10g common salt (sodium ehlorh:le)in 100ml <strong>of</strong><br />

water. Soaking in brine has to be done only where ergot infection i5 noticed byt within the<br />

prescribed field standard. <strong>The</strong> <strong>seed</strong> is to be dipped in brine solution for 5-1 a min and ergot<br />

sclerotia removed. <strong>The</strong> send is washed thoroughly with water.<br />

2. <strong>The</strong> <strong>seed</strong> is to be treated only if loose smut infection is suspected or detected in the <strong>seed</strong>.<br />

BAGGING, TAGGING, SEALING AND GRANT OF CERTIFICATE<br />

Every <strong>seed</strong> lot meeting the prescribed <strong>seed</strong> standard!;; for certification is duly treated with the<br />

recommended <strong>seed</strong>-treatment chemical and is bagged in required si~es affixing ;:;eed certification tags<br />

(blue tags for certified <strong>seed</strong> and' white tags for foundation <strong>seed</strong>) and the containtJf ig seal@d. This is<br />

followed by issue <strong>of</strong> the Release Order (Form-II) for each <strong>seed</strong> lot.<br />

VALIDITY PERIOD OF THE CERTIFICATE<br />

<strong>The</strong> validity period <strong>of</strong> the <strong>seed</strong> lot will be nine months from the date <strong>of</strong> test at the time <strong>of</strong> initi(!1<br />

certification. <strong>The</strong> validity period may be further extended for six months provided the <strong>seed</strong> conforms to<br />

, the prescribed standards on re<strong>testing</strong>. A <strong>seed</strong> lot will be eligible for extension <strong>of</strong> the validity period as long<br />

as it conforms to the prescribed standards. <strong>The</strong> procedure for extension <strong>of</strong> validity is as follows.<br />

Holder <strong>of</strong> the certified <strong>seed</strong> stock or authorized representative may request the Agency for<br />

extension <strong>of</strong> the validity <strong>of</strong> certified <strong>seed</strong> before expiry <strong>of</strong> the previous validity, Informatjc;>n regarding<br />

name <strong>of</strong> the crop, variety, class <strong>of</strong> <strong>seed</strong>, quantity <strong>of</strong> <strong>seed</strong> in lot, lot number, size andtype <strong>of</strong> container;:;,<br />

Release Order No. etc., should be fumished to the Agency at the time <strong>of</strong> submission <strong>of</strong> application,<br />

<strong>The</strong> Agency will arrange for the drawing <strong>of</strong> <strong>seed</strong> sample and its analysis after verifying the tags,<br />

labels, seals and validity period. <strong>The</strong> sample is tested for physical purity, germination and insect damage.<br />

If reprocessing, <strong>testing</strong> and rebagging at the time <strong>of</strong> extension <strong>of</strong> validity period is requested, it may also<br />

be considered if the Agency is <strong>of</strong> the opinion that such operation may improve the quality <strong>of</strong> <strong>seed</strong>,<br />

After analysis <strong>of</strong> the'<strong>seed</strong> sample, if <strong>seed</strong> is found to conform to the prescribed standards, the<br />

Agency will extend the validity <strong>of</strong> the <strong>seed</strong> for a further period <strong>of</strong> six months from the date <strong>of</strong> test. <strong>The</strong> date<br />

<strong>of</strong> test and the validity period shall be stamped<br />

on existing tags or new tags shall be issued. <strong>The</strong> signature<br />

and address <strong>of</strong> the Seed Certification Officer attending to the validity work are also affixed on the tag. If<br />

new tags are issued the information in the old tags will be transferred to the new tags allotted, A complete<br />

record <strong>of</strong> the validation process will be <strong>main</strong>tained by the Agency.<br />

REVOCATION OF CERTIFICATE<br />

If the Agency is satisfied, either on reference made to it in this behalf <strong>of</strong> or otherwise that (a) the<br />

certificate granted by it under Section-9(3) <strong>of</strong> the Seed Act has been obtained by misrepresentation as to<br />

an essential fact or (b) the holder <strong>of</strong> the certificate has, without reasonable cause, failed to comply with<br />

the conditions subject to which the certificate has been granted or has contravened any <strong>of</strong> the provisions<br />

<strong>of</strong> the Act or the Rules made there-under, then, without prejudice to any other penalty to which the holder<br />

<strong>of</strong> the certificate may be liable under the Act, the Agency may, after giving the holder <strong>of</strong> the certificate an<br />

opportunity <strong>of</strong> showing cause, revoke the certificate under the provisions <strong>of</strong> Section -10 <strong>of</strong> the Act.<br />

REFUSAL FOR CERTIFICATION AND APPEALS<br />

<strong>The</strong> Agency shall have the authority. to refuse certification <strong>of</strong> any <strong>seed</strong> production field or,any<br />

<strong>seed</strong> that does not conform to the minimum standards prescribed for the that particular crop either for<br />

38

field or for <strong>seed</strong> or for both. Such refusal will be subject to appeal made to the Appellate authority constituted<br />

under Section -11 (1) <strong>of</strong> the Seeds Act. 1966.<br />

All such appeals should be made within 30 days from the date on which the decision <strong>of</strong> the<br />

Agency is communicated, enclosing a copy <strong>of</strong> the decision <strong>of</strong> Agency against which appeal is being<br />

preferred with the grounds for objection to such decision and a bank draft for Rs. 100.00 (Rupees one<br />

hundred only) towards<br />

appeal fees.<br />

DOWNGRADING<br />

OF <strong>SEED</strong> CLASS<br />

If a <strong>seed</strong> field or a <strong>seed</strong> lot registered but is not found meeting prescribed standards for the class for<br />

,<br />

I<br />

.<br />

r<br />

I<br />

I<br />

I<br />

which it hasb~!3n confirms to the prescribed standards to the immediate lower class, the certification<br />

Agency may accept such <strong>seed</strong> fields/<strong>seed</strong> lots for certification to immediate lower class provided request<br />

has been made to this effect by the <strong>seed</strong> producer. However, downgrading <strong>of</strong> the <strong>seed</strong> class shall not be<br />

applicable<br />

in case <strong>of</strong> Hybrids their parents.<br />

RECLEANING, RESAMPLING &. RE<strong>TESTING</strong><br />

When a <strong>seed</strong> lot does not meet the prescribed <strong>seed</strong> standards certification agency on the request <strong>of</strong> <strong>seed</strong><br />

producer may permit Recleaning, Resampling and Re<strong>testing</strong> duly collecting the necessary charges. <strong>The</strong><br />

recleaning, resampling and re<strong>testing</strong> shall be permitted only once.<br />

RETENTION OF CERTIFICATION RECORD<br />

<strong>The</strong> certification agency shall preserve in order all the documents including the guard samples pertaining<br />

to certification <strong>of</strong> each <strong>seed</strong> lot for two (2) years from the date <strong>of</strong> grant / extension <strong>of</strong> the certificate and<br />

four (4) years in respect <strong>of</strong> rejected <strong>seed</strong> crops or lots from the date <strong>of</strong> communication <strong>of</strong> rejection unless<br />

and otherwise required for longer period.<br />

LEGAL STATUS OF CERTIFICATION<br />

SYSTEM:<br />

/Under Seeds Act 1966 "Seed Certificatiol')" has become a legally sanctioned system <strong>of</strong> quality control <strong>of</strong><br />

Seed during Production/Multiplication and distribution stages and relates to:<br />

1<br />

a) Section-8<br />

b) Section-8(A)<br />

c) Section-9<br />

d) Section-10<br />

e) Section-11<br />

f) Part-IV<br />

Refers establishment <strong>of</strong> Seed Certification Agency at state level to<br />

discharge the function <strong>of</strong> certification.<br />

Refers to establishment <strong>of</strong> Central Certification Board primarily to render<br />

advisory on scientific and operational matters.<br />

Refers to grant <strong>of</strong> Certificate by the Certificate Agency as prescribed to a<br />

Seed lot <strong>of</strong>fered for Certification.<br />

Refers to 'evocation <strong>of</strong> Certificate issued, on breach <strong>of</strong> trust or non<br />

accomplishment <strong>of</strong> procedure prescribed.<br />

Refers to appeals by Growers against the decision(s) <strong>of</strong> the Seed<br />

Certification Agency to an appelant authority.<br />

Refers to function <strong>of</strong> Seed Certification Agency to regulate <strong>seed</strong> quality<br />

(S€ed Rule-6) Prescribing procedure for growing, processing storage<br />

etc. <strong>of</strong> <strong>seed</strong> crop<br />

'On

Arranging notification <strong>of</strong> varieties,processing plants, field inspections etc. for the confirmation <strong>of</strong> field<br />

standards.<br />

Carrying out the education programmes to promote the use <strong>of</strong> certified Seed. Sampling Seed lots for<br />

<strong>testing</strong> to confirm Seed Standards.<br />

Issuance <strong>of</strong> Certificate, tag seal etc.<br />

INTRODUCTION OF <strong>SEED</strong> ACT 1966<br />

<strong>The</strong> Government <strong>of</strong> <strong>India</strong> enacted the sed act in 1966 and the <strong>seed</strong> rules under the act are framed in<br />

1968. <strong>The</strong> <strong>seed</strong>s Act 1966 and the <strong>seed</strong> Rules 1968 with the amendements carried out from time to<br />

time are in existence and inforce as on to day. -'<br />

DECLARING THE <strong>SEED</strong> AS ESSENTIAL COMMODITY<br />

<strong>The</strong> Government <strong>of</strong> <strong>India</strong> on 24th February, 1983 have declared the <strong>seed</strong>s <strong>of</strong> food crops, fruits and<br />

vegetables, cotton <strong>seed</strong>s, <strong>seed</strong>s <strong>of</strong> cattle fodder and jute <strong>seed</strong>s as essential commodities under section<br />

2 <strong>of</strong> Essential Commodity Act 1955 (10 <strong>of</strong> 1955) 'and a <strong>seed</strong>s (control) order was issued in December'<br />

1983. This control order provide to control and regulate the production, supply and distribution <strong>of</strong> <strong>seed</strong>s<br />

by effective check on the activities <strong>of</strong> the dealers and producers <strong>of</strong> <strong>seed</strong>.<br />

<strong>The</strong> salient features <strong>of</strong> the Seeds Act 1966, <strong>seed</strong>s rules 1968 and the <strong>seed</strong>s (control) order 1983.<br />

THE <strong>SEED</strong> ACT 1966<br />

<strong>The</strong> Seeds Act 1966 is <strong>main</strong>ly applicable to the notified kind <strong>of</strong> variety in relation to any <strong>seed</strong> under<br />

section 5. It is basically regulatory in nature and <strong>main</strong>ly to ensure that <strong>seed</strong>s <strong>of</strong> notified varieties <strong>of</strong>fered<br />

for sale conform to certain minimum limits <strong>of</strong> purity and remination,<br />

<strong>The</strong> act provides -the onstruction <strong>of</strong> central <strong>seed</strong> committee to advice central govemment on all<br />

matters arising out <strong>of</strong> the administration <strong>of</strong> this Act.<br />

(section 3) to establish a central <strong>seed</strong> laboratory or declare the laboratories as central or state<br />

(section 4)<br />

" (section 5)<br />

(section 6)<br />

(section 7)<br />

(section 8)<br />

<strong>seed</strong> laboratorieswhere analysis <strong>of</strong> <strong>seed</strong>s <strong>of</strong> anyh notified kind or variety shall be<br />

carried<br />

out by <strong>seed</strong> analyst.<br />

to notify any kind or variety to be sold for the purpose<br />

<strong>of</strong> agriculture.<br />

to presribe minimum limits <strong>of</strong> germination and purity standards for each category<br />

<strong>of</strong> <strong>seed</strong>s and label the <strong>seed</strong> indicating the standards. .<br />

Regulation <strong>of</strong> sale <strong>of</strong> <strong>seed</strong>s <strong>of</strong> notified kinds <strong>of</strong> varities,<br />

to establish certification agency for the states.<br />

to establish central <strong>seed</strong> certification Board and other committees,<br />

(pection 8A to 8E)<br />

to appoint <strong>seed</strong> Analysts, <strong>seed</strong> inspectors and specify their powers, functions and<br />

duties.<br />

(section 12 to 16) ti regulate, impose certain restrictions on export <strong>of</strong> <strong>seed</strong>s <strong>of</strong> notified kinds <strong>of</strong><br />

varieties.<br />

(section 17) to impose certain penalities for the <strong>of</strong>fences committed under Act.<br />

" . (section 18) '- to make rules and gives proteqtion <strong>of</strong> action taken in good faith.<br />

(section 25 and" 22)

V<br />

THE <strong>SEED</strong> RULES 1968<br />

<strong>The</strong> <strong>seed</strong> rules. are framed in the year 1968 giving wider scoppe <strong>of</strong> understanding various provisions <strong>of</strong><br />

the <strong>seed</strong>s Act 1966. <strong>The</strong> function <strong>of</strong> Cental Seed Laboratory, Sees Ceertification Agency are elaborated<br />

dealth with. It made labelling <strong>of</strong> any notified kind <strong>of</strong> variety <strong>of</strong> <strong>seed</strong> compulsory. It provided certain<br />

requirement to be compiled with the person carrying on the business <strong>of</strong> selling <strong>seed</strong>. <strong>The</strong>se rules also<br />

dealt the following issues.<br />

Categorised the certified <strong>seed</strong> in to three distinct classes.<br />

Certification procedures are dealt in detail.<br />

Qualification <strong>of</strong> <strong>seed</strong> Analysts and his duties are specified.<br />

'Qualification <strong>of</strong> <strong>seed</strong> inspectors and his duties are qidely defined.<br />

Seed samplihg prodecures are dealt in detail.<br />

Maintence <strong>of</strong> various records and issung <strong>of</strong> memorandum in form VII by <strong>seed</strong> inspector to the<br />

dealer.' .<br />

<strong>SEED</strong>S (CONTROL) ORDER 1983<br />

<strong>The</strong> <strong>seed</strong>s (control) order 1983 is promulgated under essential commodities Act <strong>of</strong> 1955 <strong>main</strong>ly with a<br />

view to evolve a mechanism for registration <strong>of</strong> <strong>seed</strong> dealers, get regular floe <strong>of</strong> information on <strong>seed</strong><br />

production ;and sales and to ensure suitable<br />

<strong>of</strong> <strong>seed</strong>s all over the country.<br />

<strong>The</strong> order provides for drawing <strong>of</strong> samples <strong>of</strong> <strong>seed</strong>s including truthful labelled <strong>seed</strong>s and does not<br />

envisage any requirement <strong>of</strong> sale <strong>of</strong> only notified <strong>seed</strong>. <strong>The</strong> <strong>seed</strong> control order 1983 envisages the<br />

obligations on the part <strong>of</strong> the dealer to obtain licence (clause 3)<br />

Display stock board and price list (clause 8).<br />

Gice memorandum <strong>of</strong> cash or credi(ta:the purchaser (clause 9).<br />

Maintain records and submission <strong>of</strong> reports (clause 18)<br />

Ensure suitable distribution <strong>of</strong> <strong>seed</strong>s (clause 10)<br />

<strong>SEED</strong> PRODUCTION<br />

MANAGEMENT<br />

Several factors are responsible for successful <strong>seed</strong> production <strong>of</strong> hybrids, as <strong>seed</strong> production is a highly<br />

commercial venture, it is essential to <strong>main</strong>tain high level <strong>of</strong> crop management in order to maximise<br />

production. -<br />

Selection <strong>of</strong> Site and Field Preparations: <strong>The</strong> <strong>main</strong> consideration for selection <strong>of</strong> site are suitable<br />

climatic conditions, assured rainfall or irrigation facilitity, and dry weather at harvest. <strong>The</strong> land selected for<br />

<strong>seed</strong> production should be uniform with good drainage. <strong>The</strong> <strong>seed</strong> procluction programmes are to be<br />

organised primarily in areas which are suitable for producing good quality <strong>seed</strong>s. <strong>The</strong> <strong>seed</strong> plot must also<br />

have the required isolation distance to <strong>main</strong>tain purity <strong>of</strong> the <strong>seed</strong>, <strong>The</strong> <strong>seed</strong> production is to be taken up<br />

with enterprising farming community in areas where the <strong>seed</strong> yields are high and is more economical.<br />

<strong>The</strong> <strong>seed</strong> production is to be concentrated in few clusters <strong>of</strong> villages. Each cluster can have 2-3 continuous<br />

villages. <strong>The</strong> number <strong>of</strong> clusters can be decided on the total <strong>seed</strong> required as per the estimation <strong>of</strong> the<br />

demand and supply. Compact blocks are easy for supervision and <strong>main</strong>tenance <strong>of</strong> quality with I~ss isolation<br />

problems, <strong>The</strong>se clusters will minimize the nicking problems to a major extent and will also Serve as<br />

demonstration blocks.<br />

41

FACTORS INFLUENCING HYBRID <strong>SEED</strong> PRODUCTION<br />

i. Planting ratio: <strong>The</strong> ideal planting ratio between male and female lines is two male rows alternated<br />

by 4 to 6 female rows. Where the male line has smaller earheads and shorter span <strong>of</strong> flowering<br />

compared to the female ones, it is desirable to allow only four female rows.for each pair <strong>of</strong> male<br />

rows. <strong>The</strong> female rows can be increased to six where the male line has larger panicle and longer<br />

span <strong>of</strong> flowering5-row thick border all round the <strong>seed</strong> production plots, must always be provided.<br />

ii.<br />

Plant height: Differencein heightbetween the two parents has considerable bearing on <strong>seed</strong> setting.<br />

Where the parents are <strong>of</strong> similar height or ~here the male parent is taller than the <strong>seed</strong> parent, no<br />

difficultyis usually experienced for good- set. But, if the pollen parent is considerably shorter than<br />

the <strong>seed</strong> parent obtaining good <strong>seed</strong> set even when the niking is proper is rather difficult.This<br />

problem can be avoided to some extent by planting the short parent on the raised ridges and the<br />

taller parent in the furrows below. Urea sprays also enable to increase the height to some extent by<br />

elongating the penduncle.<br />

iii. Nicking: <strong>The</strong> most serious problem faced in hybrids <strong>seed</strong> production is proper nicking or<br />

synchronization<strong>of</strong>floweringbetween the two parents. All<strong>seed</strong> producers must understand thoroughly<br />

about the floweringtime <strong>of</strong> the p~rents indifferentseasons and at differentlocations, receptivity<strong>of</strong><br />

stigma, pollen dispersal and its viabilityaccordingly the planting <strong>of</strong> the parents willbe undertaken in<br />

<strong>seed</strong> production plots. Several methods are employed to overcome this problem depending upon<br />

the situation. <strong>The</strong> commonly followedtechnique is staggered planting, Le. ,adjusting the planting<br />

dates <strong>of</strong> the parents so that they flowersimultaneusly. Ifthe difference in 'floweringbetween the two<br />

parents is only 2 to 4 days. It is possible to bridge the gap through selective application <strong>of</strong> foliar<br />

sprays. (spray <strong>of</strong> urea @ 2% z to the late flowering).<strong>The</strong> application <strong>of</strong> urea sprays has to be taken<br />

up at flowerprimordialinitiationstage (between 30-40 days after planting) and repeated 3 to 5 times<br />

on alternative days. If the 'gap between the parents is <strong>of</strong> greater magnitude (more than 15 days)<br />

transplanting or ratooning<strong>of</strong> the earlyparent at appropriate time could be followed.As an emergency<br />

measure dusting or spraying <strong>of</strong> pollen collected from the male parent, ifavailable in the vicinitycan<br />

be done.<br />

iv.<br />

v.<br />

Flowering and pollen dispersal: <strong>The</strong> longer the duration <strong>of</strong> floweringin the male line is better as<br />

pollen is available for more number <strong>of</strong> days. Since pollen is viable only for few hours after flower<br />

opening which usually takes place in the early hourse, there is need to prolong the duration <strong>of</strong><br />

flowering<strong>of</strong> male line to ensure better <strong>seed</strong> set. This can be achieved by pollination,itis not safe to<br />

rely entirely on natural wind to aid in pollen dispersal. It is desirable using artificialaids <strong>of</strong> pollen<br />

dispersal liketapping the male plants or blowingair through empty dusters over the male heads. Itis<br />

also advisable to spray 0.2% Borax to improve the pollen production and dispersal.<br />

Stigma receptivity and pollen production: Generally, the stigma retains good receptivityupto 5<br />

days after floweropening, although insome lines it is extended beyond that period. However,during<br />

hot summer months the production is also influenced by temperatures. During winter months.<br />

especially in areas in where the night temperatures are rather low,pollen production is appreciably<br />

reduced. 0.2% Borax spray on both male and female lines two times from ear head emergence till<br />

the completion <strong>of</strong> anthesis would greatly solve the problem;<br />

4

stEPS TOIMPROVE<strong>SEED</strong> QUALITY<br />

Th important <strong>seed</strong> quality parameters are <strong>main</strong>tenance <strong>of</strong> high standards <strong>of</strong> genetic purity, germination<br />

and physical purity,<br />

I) Roguing: <strong>The</strong> problem <strong>of</strong> genetic purity can be solved by adopting timely roghlng In the <strong>seed</strong> plots<br />

and <strong>main</strong>thenal1ce <strong>of</strong> prescribed isolation distance. <strong>The</strong> removal <strong>of</strong> <strong>of</strong>f-types and diseased plants<br />

Horti tlie seeos field before they start flowering is known as rouging. This is done to avoid<br />

contamination, out ct6Ssing and transmission <strong>of</strong> <strong>seed</strong> borne dieseases. Scientifically, roguing is the<br />

process <strong>of</strong> negative mass selection in which '<strong>of</strong>f types' are removed and only 'true to' plants are<br />

retained, in the whole population <strong>of</strong> <strong>seed</strong> crop. In self pollinated cops rouging should be continuously<br />

practlMd while In cross pollinated crops. It must be completed well before the commencement <strong>of</strong><br />

anthesis. <strong>The</strong> anthers start shedding <strong>of</strong> pollen after anthesis and thus become the source <strong>of</strong><br />

contamination.<br />

rows.<br />

In hybrid <strong>seed</strong> production, this procedure is to be carried out both in <strong>seed</strong> and pollinator<br />

Ii) Control <strong>of</strong> pests' and diseases: <strong>The</strong> incidence <strong>of</strong> pest and diseases 'could cause serious yield<br />

losses both in quantity and quality if not controlled in time. Complete immunity from designated<br />

diseases in cultivated crops is perhaps difficult. But a fair degree <strong>of</strong> resistance is always kept in view<br />

by the breeder while evaluating crop varities for release. <strong>The</strong> environmental conditions playa key<br />

role in the perpetuation and spred <strong>of</strong> the disease inoculum or multiplication <strong>of</strong> insects which effect<br />

the <strong>seed</strong> crop at different growth phases. <strong>The</strong> necessitates prophylatic control measures right from<br />

the stage <strong>of</strong> <strong>seed</strong>bed preparation to the harvesting stage. Use <strong>of</strong> prescribed fungicides!insecticides<br />

as may be available at regular intervals not only ensures the helath <strong>of</strong> the crop but also increases<br />

the <strong>seed</strong> yield considerably. Common practices for the control <strong>of</strong> pests and diseases are: (a) Soil<br />

and Seed treatment, (b) Spraying! dusting on the standing crop at various stages. <strong>The</strong> concentration<br />

<strong>of</strong> fungicides! insecticides should be adjusted in such a way that there is no scorching effect on the<br />

crop and the <strong>objective</strong>s to arrest the spread <strong>of</strong> inoculum! insect activity is fulfilled.<br />

iii) Harvesting and post-harvesting handling <strong>of</strong> <strong>seed</strong> crop: Supervising harvesting and after-care<br />

during' post harvest handling <strong>of</strong> <strong>seed</strong> crops are integral part <strong>of</strong> the certification scheme. <strong>The</strong> time,<br />

energy and money spent on growing genetically and disease-free <strong>seed</strong> crops may go waste if the<br />

harvested <strong>seed</strong> crops are left to the vagaris <strong>of</strong> weather conditions<br />

or if steps are not taken to complete<br />

its processing such as threshing, winnowing, drying, cleaning, grading <strong>seed</strong> treatment, packaging,<br />

labelling and sealing later movement <strong>of</strong> the <strong>seed</strong> lots <strong>of</strong> safe storage.<br />

STAGES OF PRECAUTIONS<br />

a. Harvesting and threshing: <strong>seed</strong>, on attaining physiological maturity in the field should be harvested.<br />

b.<br />

since it acquiries the highest degree <strong>of</strong> vigour and viability which gradually declines as it approaches<br />

the field maturity. Moisture content is the major criteria for keeping quality.<br />

Dryings: Seed produce, after harvesting and threshing, is subjected to sun drying to reduce the<br />

moisture content at the production site itself before transporting it to the processing plant. Seed<br />

produce should not be exposed to direct sunlight as it affects its quality, therefore, if necessary <strong>seed</strong><br />

IS dried under diffused sunflight in shade.<br />

Grading: Grading is done by using different models <strong>of</strong> graders with prescribed aperture-size screens.<br />

4::\

d. Seed treatment: Treatment <strong>of</strong> <strong>seed</strong> with the prescribed doses <strong>of</strong> fungicides and insecticides avoids<br />

the diseases-causing pathogens and insects carried with <strong>seed</strong>s or their fresh entry in to it. <strong>The</strong><br />

cliemicals generally used for <strong>seed</strong> tretment are (a) organomercurials such as agrosan, (b) organononmetallics<br />

such as Capton and Thlram, and (c) Inorganlc-metallics and non-mettallics like copper and<br />

e.<br />

f.<br />

iv.<br />

sulphur<br />

compounds.<br />

Packing: It is necessary to use the right type <strong>of</strong> unit packing material or containers to <strong>main</strong>tain the<br />

quality to <strong>seed</strong>. <strong>The</strong> moisture content <strong>of</strong> the <strong>seed</strong> should be bought down to 6 to 8% if the <strong>seed</strong> is to<br />

be packed in vapour-pro<strong>of</strong> containers, and to 12% level for non vapour-pro<strong>of</strong> containers (Jute or<br />

cloth bag).<br />

Labelling and sealing: Each package should be labelled in the prescribed manner and thoroughly<br />

sealed to prevent tampering. It is necessary to mention on the lable the pedigree and the identity <strong>of</strong><br />

the <strong>seed</strong>s lot with respect to its status <strong>of</strong> purity, germinations, health etc. as per the requirements <strong>of</strong><br />

the <strong>seed</strong> legislation.<br />

Storage: Ample precautions'should be taken to prevent the <strong>seed</strong> lots from deteribrating while in<br />

transit and / or in storage. Emphasis should be laid on controlling stored pests and diseases and the<br />

temperature and relative humidity status <strong>of</strong> the storage. For longer and safer storage, dry and cool<br />

conditions are preferred, the ideal conditions can be <strong>main</strong>tained if the sum <strong>of</strong> RH.and temperature<br />

does not exceed 100. Temperature <strong>of</strong> 60-70° F and relative humidity <strong>of</strong> 30-40% are ideally suited for<br />

safe storage. Specific combination is to be arrived according to the ambient..