Renewable Energy in Industrial Applications â an ... - Unido

Renewable Energy in Industrial Applications â an ... - Unido

Renewable Energy in Industrial Applications â an ... - Unido

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SOLAR THERMAL SYSTEMS<br />

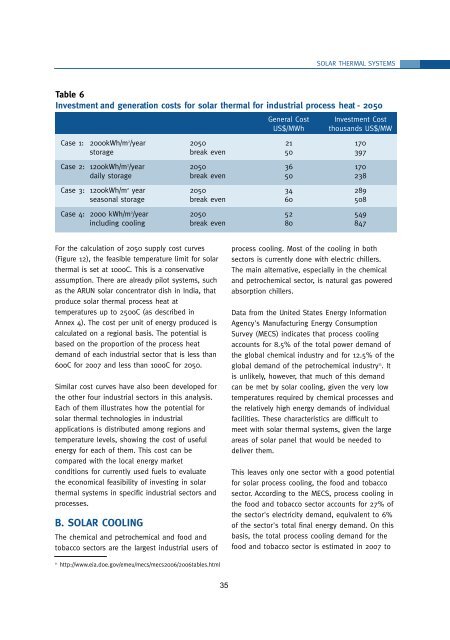

Table 6<br />

Investment <strong>an</strong>d generation costs for solar thermal for <strong>in</strong>dustrial process heat - 2050<br />

General Cost<br />

US$/MWh<br />

Investment Cost<br />

thous<strong>an</strong>ds US$/MW<br />

Case 1: 2000kWh/m 2 /year 2050 21 170<br />

storage break even 50 397<br />

Case 2: 1200kWh/m 2 /year 2050 36 170<br />

daily storage break even 50 238<br />

Case 3: 1200kWh/m 2 year 2050 34 289<br />

seasonal storage break even 60 508<br />

Case 4: 2000 kWh/m 2 /year 2050 52 549<br />

<strong>in</strong>clud<strong>in</strong>g cool<strong>in</strong>g break even 80 847<br />

For the calculation of 2050 supply cost curves<br />

(Figure 12), the feasible temperature limit for solar<br />

thermal is set at 100oC. This is a conservative<br />

assumption. There are already pilot systems, such<br />

as the ARUN solar concentrator dish <strong>in</strong> India, that<br />

produce solar thermal process heat at<br />

temperatures up to 250oC (as described <strong>in</strong><br />

Annex 4). The cost per unit of energy produced is<br />

calculated on a regional basis. The potential is<br />

based on the proportion of the process heat<br />

dem<strong>an</strong>d of each <strong>in</strong>dustrial sector that is less th<strong>an</strong><br />

60oC for 2007 <strong>an</strong>d less th<strong>an</strong> 100oC for 2050.<br />

Similar cost curves have also been developed for<br />

the other four <strong>in</strong>dustrial sectors <strong>in</strong> this <strong>an</strong>alysis.<br />

Each of them illustrates how the potential for<br />

solar thermal technologies <strong>in</strong> <strong>in</strong>dustrial<br />

applications is distributed among regions <strong>an</strong>d<br />

temperature levels, show<strong>in</strong>g the cost of useful<br />

energy for each of them. This cost c<strong>an</strong> be<br />

compared with the local energy market<br />

conditions for currently used fuels to evaluate<br />

the economical feasibility of <strong>in</strong>vest<strong>in</strong>g <strong>in</strong> solar<br />

thermal systems <strong>in</strong> specific <strong>in</strong>dustrial sectors <strong>an</strong>d<br />

processes.<br />

B. SOLAR COOLING<br />

The chemical <strong>an</strong>d petrochemical <strong>an</strong>d food <strong>an</strong>d<br />

tobacco sectors are the largest <strong>in</strong>dustrial users of<br />

process cool<strong>in</strong>g. Most of the cool<strong>in</strong>g <strong>in</strong> both<br />

sectors is currently done with electric chillers.<br />

The ma<strong>in</strong> alternative, especially <strong>in</strong> the chemical<br />

<strong>an</strong>d petrochemical sector, is natural gas powered<br />

absorption chillers.<br />

Data from the United States <strong>Energy</strong> Information<br />

Agency's M<strong>an</strong>ufactur<strong>in</strong>g <strong>Energy</strong> Consumption<br />

Survey (MECS) <strong>in</strong>dicates that process cool<strong>in</strong>g<br />

accounts for 8.5% of the total power dem<strong>an</strong>d of<br />

the global chemical <strong>in</strong>dustry <strong>an</strong>d for 12.5% of the<br />

global dem<strong>an</strong>d of the petrochemical <strong>in</strong>dustry 11 . It<br />

is unlikely, however, that much of this dem<strong>an</strong>d<br />

c<strong>an</strong> be met by solar cool<strong>in</strong>g, given the very low<br />

temperatures required by chemical processes <strong>an</strong>d<br />

the relatively high energy dem<strong>an</strong>ds of <strong>in</strong>dividual<br />

facilities. These characteristics are difficult to<br />

meet with solar thermal systems, given the large<br />

areas of solar p<strong>an</strong>el that would be needed to<br />

deliver them.<br />

This leaves only one sector with a good potential<br />

for solar process cool<strong>in</strong>g, the food <strong>an</strong>d tobacco<br />

sector. Accord<strong>in</strong>g to the MECS, process cool<strong>in</strong>g <strong>in</strong><br />

the food <strong>an</strong>d tobacco sector accounts for 27% of<br />

the sector's electricity dem<strong>an</strong>d, equivalent to 6%<br />

of the sector's total f<strong>in</strong>al energy dem<strong>an</strong>d. On this<br />

basis, the total process cool<strong>in</strong>g dem<strong>an</strong>d for the<br />

food <strong>an</strong>d tobacco sector is estimated <strong>in</strong> 2007 to<br />

11<br />

http://www.eia.doe.gov/emeu/mecs/mecs2006/2006tables.html<br />

35