MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Preparation for assembly<br />

J - Remove from the pinion rod manually the<br />

adjusting wedges of the roller bearings. (figure<br />

32).<br />

Cleaning<br />

The unit can undergo external washing, in order<br />

to facilitate its removal and disassembly. In<br />

this case, all the openings should be covered<br />

to avoid the possibility of water or humidity entering<br />

the unit.<br />

Figure 32<br />

K - Remove, if necessary the back roller bearing<br />

cone using an appropriate extractor or<br />

a press (figure 33).<br />

L - Remove and discard, if necessary, the elastic<br />

ring, using appropriate pliers.<br />

IMPORTANT :<br />

We do not recommend washing the unit with<br />

water after it has been disassembled. When<br />

this cleaning system is used, the water is retained<br />

in the parts. This can cause oxidation<br />

(rust) in critical parts and allow the circulation<br />

of these rust particles in the oil. This<br />

practice can lead to premature wear of the<br />

roller bearings, gears and other parts. Thuds,<br />

the unit should be totally disas-sembled<br />

as it cannot be cleaned suitably in another<br />

manner.<br />

NEVER USE GASOLINE<br />

Wash all the components which have ma-chined<br />

or rectified surfaces (gears, roller bearings,<br />

wedges, crosspiece) using appropriate solvents<br />

with a petroleum base, such as: diesel oil<br />

of kerosene.<br />

Wash the cast parts (satellite box, bearing covers<br />

and inside of the differential box) using the<br />

afore mentioned solvents. CAUTIONly remove<br />

all the joint particles. See the LIQUIDJOINT<br />

section.<br />

Clean the breathing plugs CAUTIONly (an air<br />

jet can be used). If it is blocked or damaged,<br />

replace it.<br />

Figure 33<br />

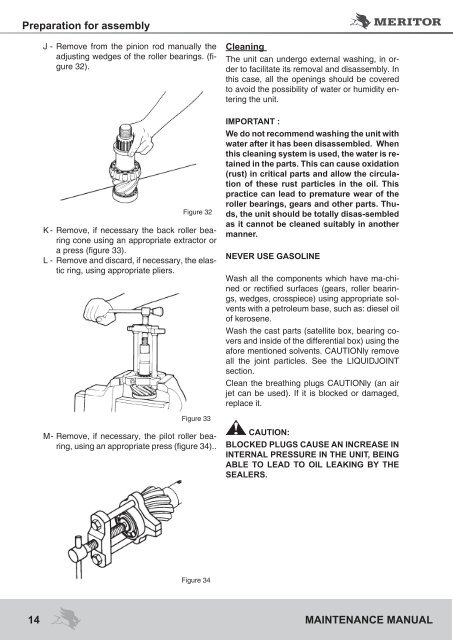

M - Remove, if necessary, the pilot roller bearing,<br />

using an appropriate press (figure 34)..<br />

CAUTION:<br />

Blocked plugs cause an increase in<br />

internal pressure in the unit, being<br />

able to lead to oil leaking by the<br />

sealers.<br />

Figure 34<br />

14 <strong>MAINTENANCE</strong> <strong>MANUAL</strong>