MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Assembly<br />

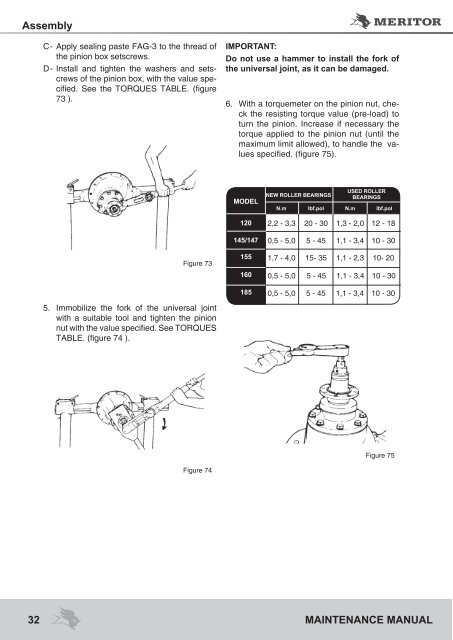

C - Apply sealing paste FAG-3 to the thread of<br />

the pinion box setscrews.<br />

D - Install and tighten the washers and setscrews<br />

of the pinion box, with the value specified.<br />

See the TORQUES TABLE. (figure<br />

73 ).<br />

IMPORTANT:<br />

Do not use a hammer to install the fork of<br />

the universal joint, as it can be damaged.<br />

6. With a torquemeter on the pinion nut, check<br />

the resisting torque value (pre-load) to<br />

turn the pinion. Increase if necessary the<br />

torque applied to the pinion nut (until the<br />

maximum limit allowed), to handle the values<br />

specified. (figure 75).<br />

MODEL<br />

USED ROLLER<br />

NEW ROLLER BEARINGS<br />

BEARINGS<br />

N.m lbf.pol N.m lbf.pol<br />

120<br />

2,2 - 3,3<br />

20 - 30<br />

1,3 - 2,0<br />

12 - 18<br />

145/147<br />

0,5 - 5,0<br />

5 - 45<br />

1,1 - 3,4<br />

10 - 30<br />

Figure 73<br />

155<br />

1,7 - 4,0<br />

15- 35 1,1 - 2,3 10- 20<br />

160<br />

0,5 - 5,0<br />

5 - 45 1,1 - 3,4 10 - 30<br />

185<br />

0,5 - 5,0<br />

5 - 45 1,1 - 3,4 10 - 30<br />

5. Immobilize the fork of the universal joint<br />

with a suitable tool and tighten the pinion<br />

nut with the value specified. See TORQUES<br />

TABLE. (figure 74 ).<br />

Figure 75<br />

Figure 74<br />

32 <strong>MAINTENANCE</strong> <strong>MANUAL</strong>